Iron core coil type current transformer with high detection precision and electric leakage detection device

A technology for current transformers and detection accuracy, which is applied in the field of leakage detection, which can solve the problems of increasing the iron core area, reducing the magnetic circuit, and difficult installation, etc., and achieves the effects of improving detection accuracy, reducing residual magnetism, and improving anti-saturation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

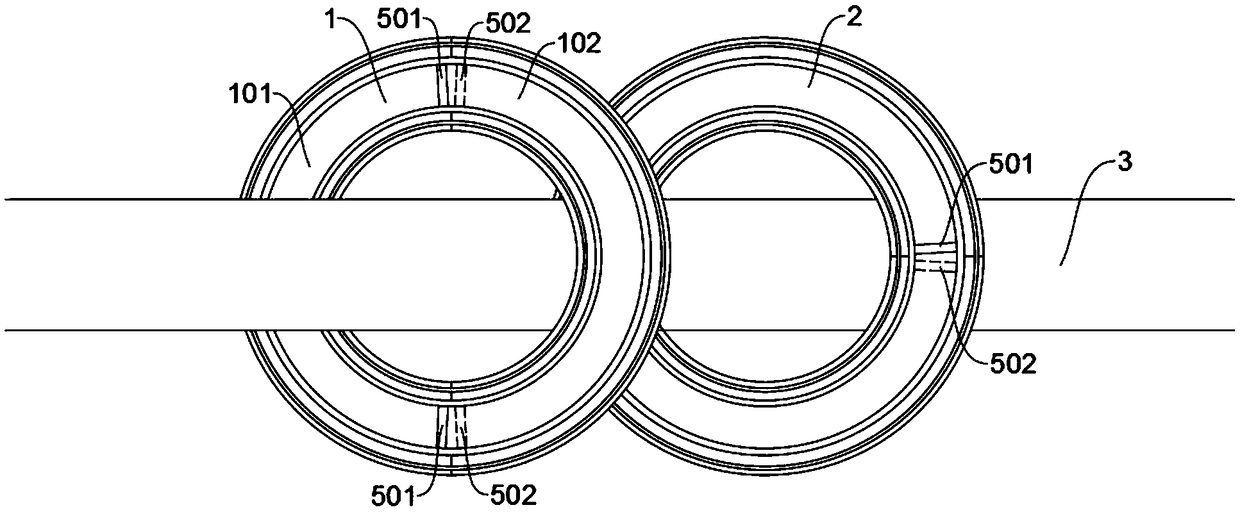

[0036] Such as figure 1 As shown, the present invention provides a core-coil current transformer with high detection accuracy, including a first core group 1 and a second core group 2, and the first core group 1 and the second core group 2 are coaxial Arranged and connected in series, the first iron core group 1 and the second iron core group 2 all include a semicircular first iron core 101 and a second iron core 102, and the first iron core 101 and the second iron core 102 are closed to form a ring. The conductor 3 of the line to be tested passes through the centers of the first core group 1 and the second core group 2 in sequence.

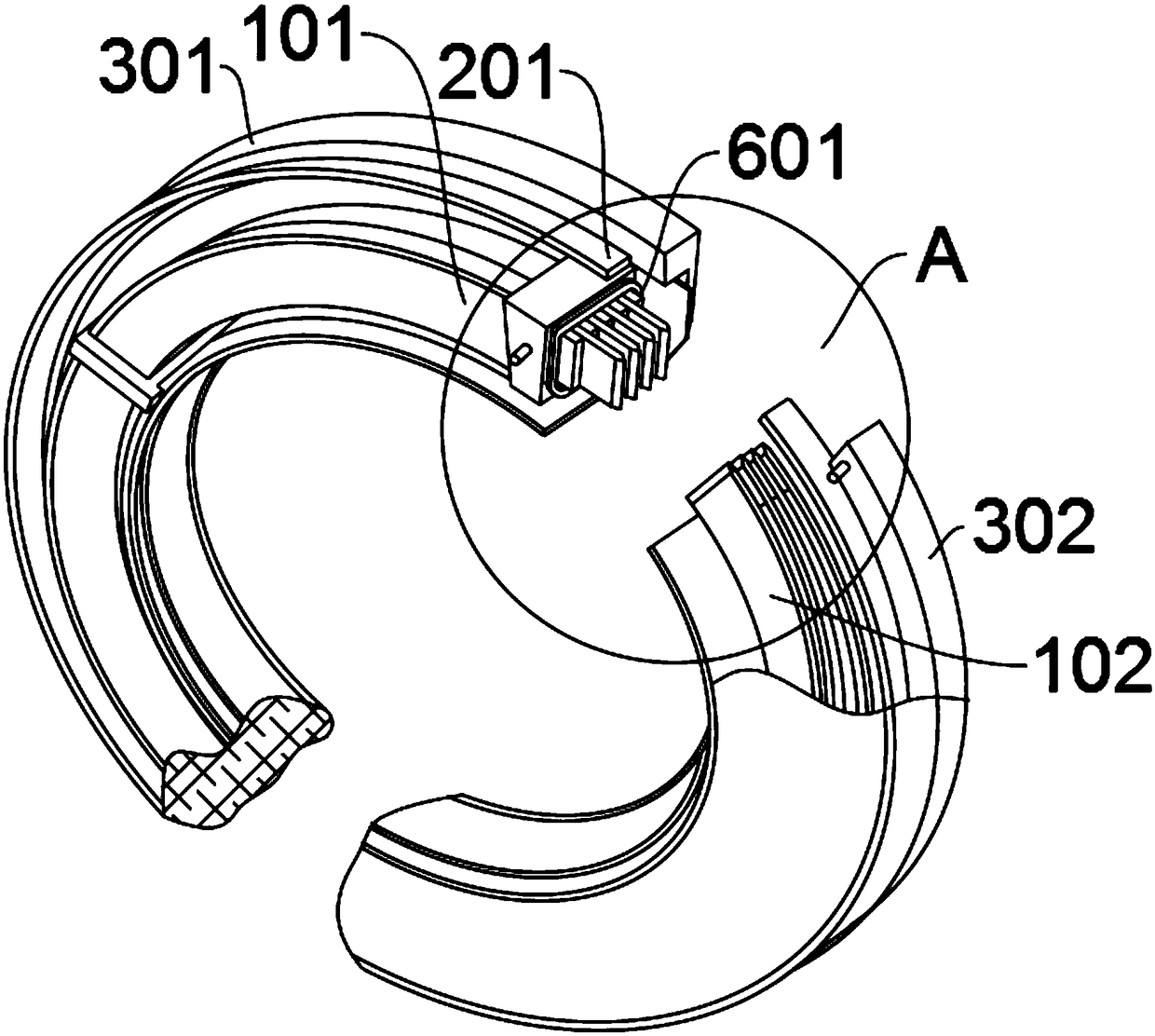

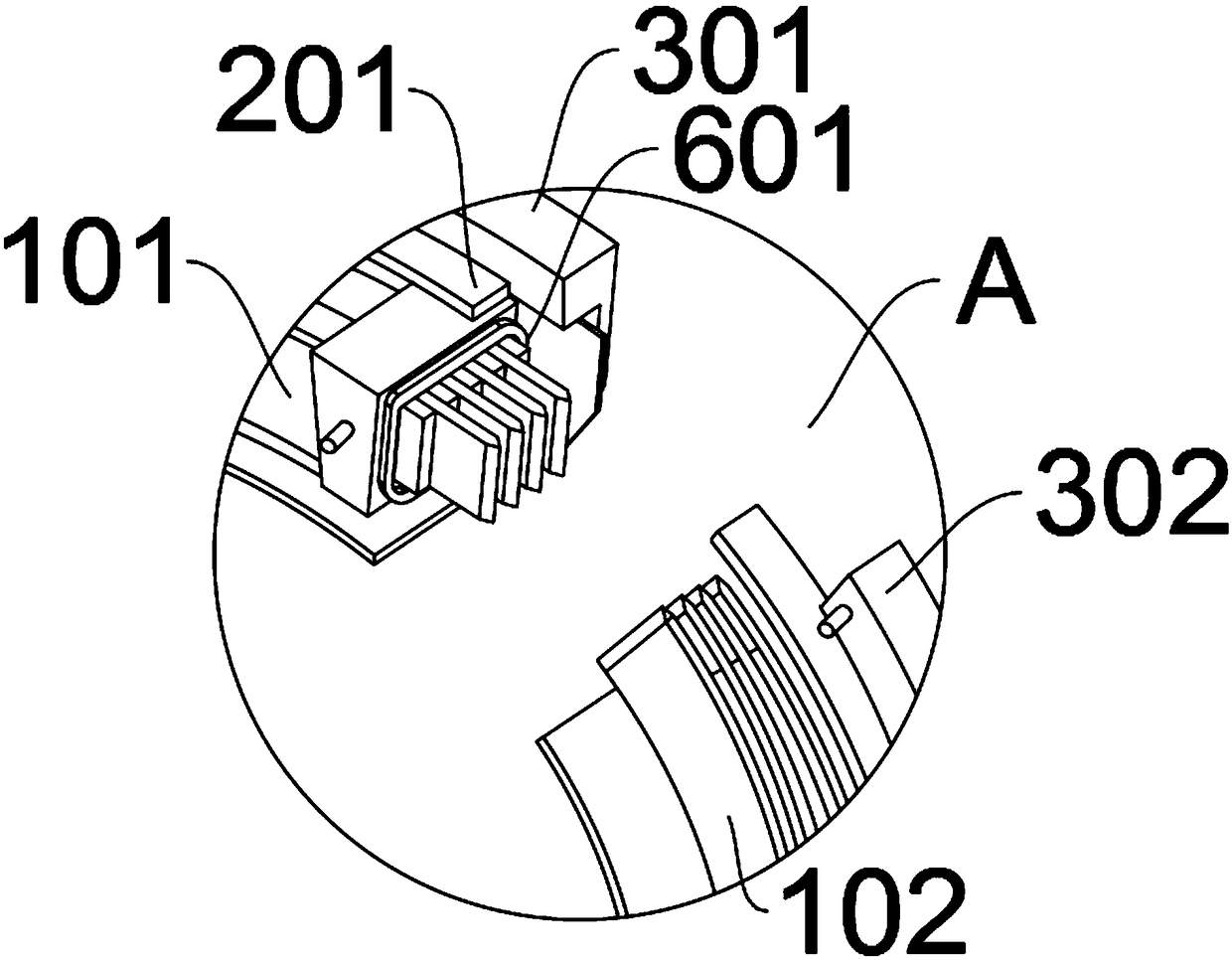

[0037] Such as figure 2 As shown, the first iron core 101 and the second iron core 102 are respectively provided with a shielding case 201, the first iron core 101 is fixed in the first semi-annular shell 301 by epoxy resin potting, and the second iron core 102 is passed through The epoxy resin is potted and fixed in the second semi-annular c...

Embodiment 2

[0046] Such as Figure 7 As shown, the present invention provides a leakage detection device with high detection accuracy, including a leakage detection terminal 10 , a concentrator 12 and a host computer 13 .

[0047] There are several electric leakage detection terminals 10, which are hung at each node to be tested respectively. Each leakage detection terminal 10 includes a current transformer 1001 , a first storage module 1002 and a wireless slave node module 1003 .

[0048] The current transformer adopts the iron core coil type current transformer with high detection accuracy of Embodiment 1. The current transformer 1001 detects the leakage data at the node to be tested and stores the leakage data in the first storage module 1002. The wireless slave node module 1003 uses The leakage data stored by the first storage module 1002 is sent out in a wireless manner. The concentrator 12 receives the data signal sent by the wireless slave node module 1003 of each leakage detecti...

Embodiment 3

[0050] Such as Figure 8 As shown, the present invention provides a leakage detection device with high detection accuracy, including a leakage detection terminal 10 , a handheld mobile terminal 11 and a host computer 13 .

[0051] There are several electric leakage detection terminals 10, which are hung at each node to be tested respectively. The leakage detection terminal 10 includes a current transformer 1001 , a first storage module 1002 and a wireless slave node module 1003 , and the handheld mobile terminal 11 includes a wireless master node module 1101 , a second storage module 1103 and a data reading port 1104 .

[0052] The current transformer adopts the iron core coil type current transformer with high detection accuracy of Embodiment 1. The current transformer 1001 detects the leakage data at the node to be tested and stores the leakage data in the first storage module 1002. The wireless slave node module 1003 uses The leakage data stored by the first storage module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com