Optimal design method for high-pressure rubber hose structure on the basis of finite element

An optimized design and high-pressure rubber hose technology, which is applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of heavy rubber hose, uneven pressure bearing, high cost, etc., to save resources, prolong service life, improve The effect of pressure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

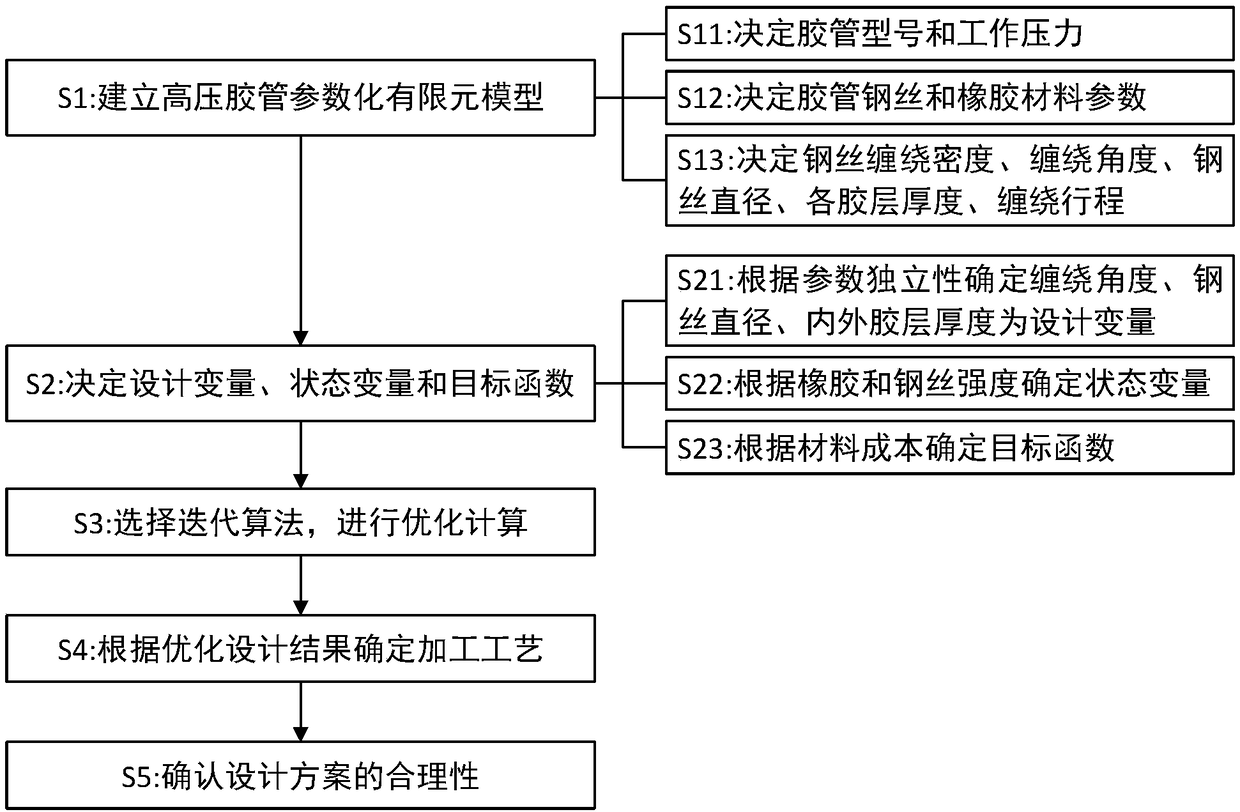

[0034] A finite element-based method for optimizing the design of the high-pressure rubber hose structure, the specific implementation mainly includes the following steps:

[0035] Step S1: Establish a parametric finite element model of the high-pressure hose, mainly including:

[0036] Step S11: Determine the type and working pressure of the high-pressure hose, and determine it with reference to API SPEC 7K-2010;

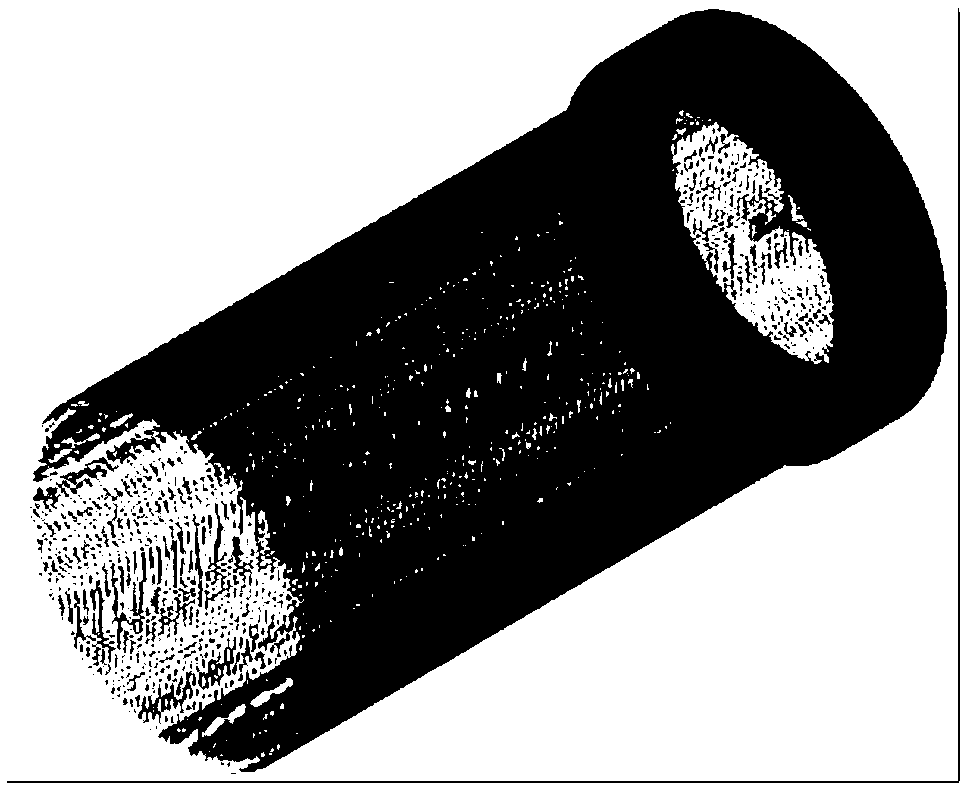

[0037] Step S12: Determine the parameters of the hose steel wire and rubber material. The model of the hose steel wire refers to the national standard GB / T 11182-2006. The rubber material is mainly nitrile rubber. The parameters of the steel wire and rubber material are determined through experiments. figure 2 ;

[0038] Step S13: Determine the wire winding density, winding angle, wire diameter, thickness of each glue layer, and winding stroke;

[0039] Its calculation formula is:

[0040]

[0041] Among them, X is the winding stroke of the designed rubber h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com