Generative Design Method for Cooling Channels of Heat Dissipating Devices Based on Meshless Galerkin Method

A heat-dissipating component, Galerkin method, applied in design optimization/simulation, geometric CAD, special data processing applications, etc., can solve problems such as limiting the layout of auxiliary materials, optimization, etc., achieving easy remodeling, solving three-dimensional problems, Easily expandable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

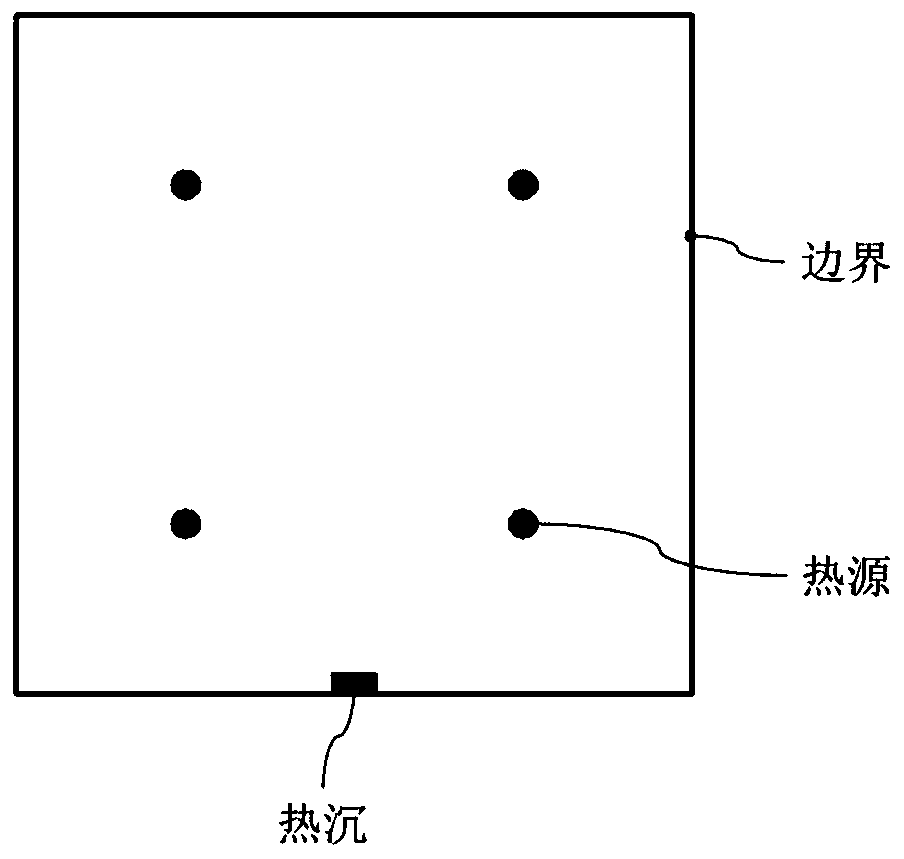

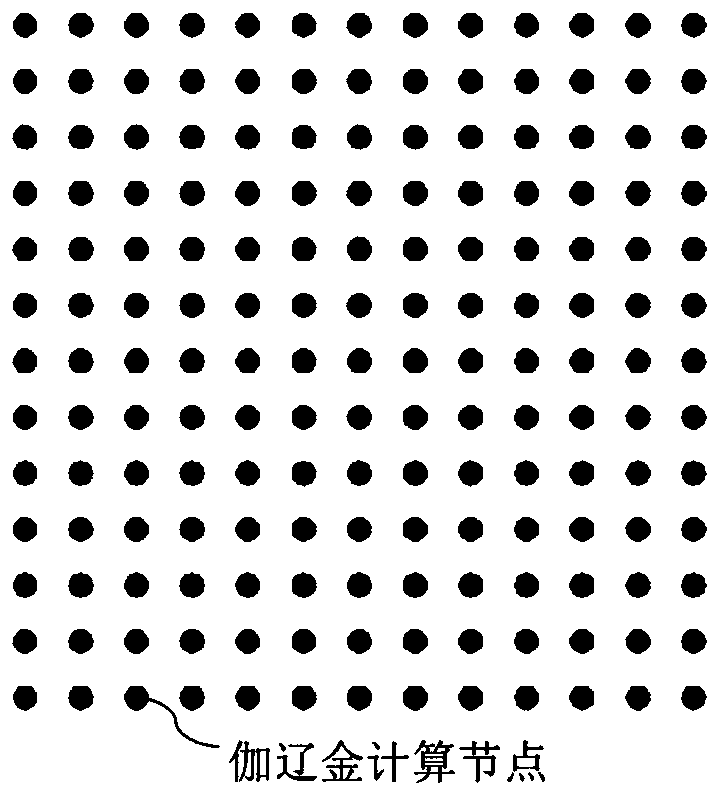

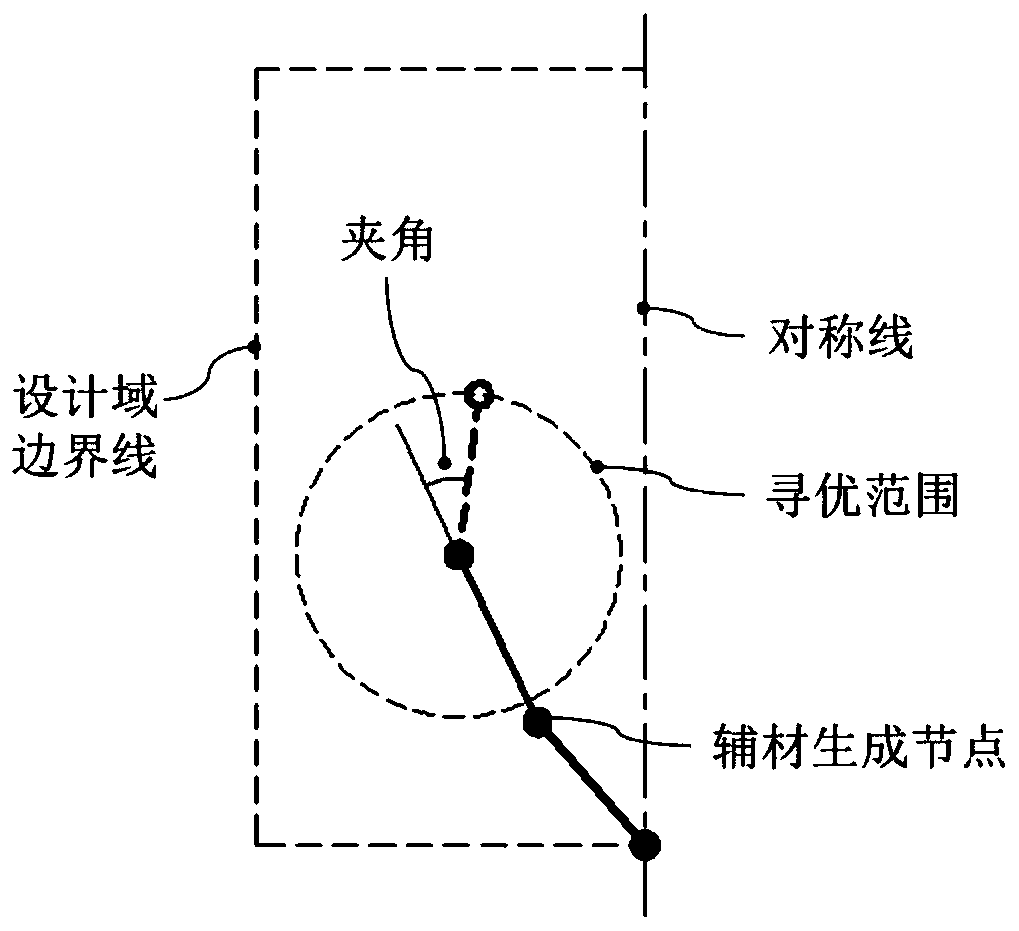

Embodiment 1

[0049] In a given 40mm x 40mm design domain base material, 81x81 evenly distributed nodes are arranged first. There are evenly distributed heat sources in the body, the four sides are insulated, and there is only one heat dissipation point at the midpoint of one side, and the temperature is 0°C. Given that the thermal conductivity of the base material is 0.01W / (m K), set each growth distance to 0.5mm; take the heat sink as the seed point, conduct a 360° range of optimization, and find the heat transfer potential capacity dissipation Minimal growth angle. And add it as a node at the end position, and set its thermal conductivity to 1W / (m·K). After that, use this node as a new seed point to continue growing. If the difference between the two growth angles before and after is greater than 90°, it is considered that the modified point has the ability to diverge, and the growth of main branches and side branches is carried out at the same time. If the growth reaches the boundary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com