Preparation method of three-dimensional luminous character with supporting layer

A support layer and luminous characters technology, applied in the field of luminous characters, can solve problems affecting the yield rate, complex structure of luminous characters, and difficulty in component positioning, so as to improve yield rate and processing efficiency, suitable for large-scale production applications, and preparation technology The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

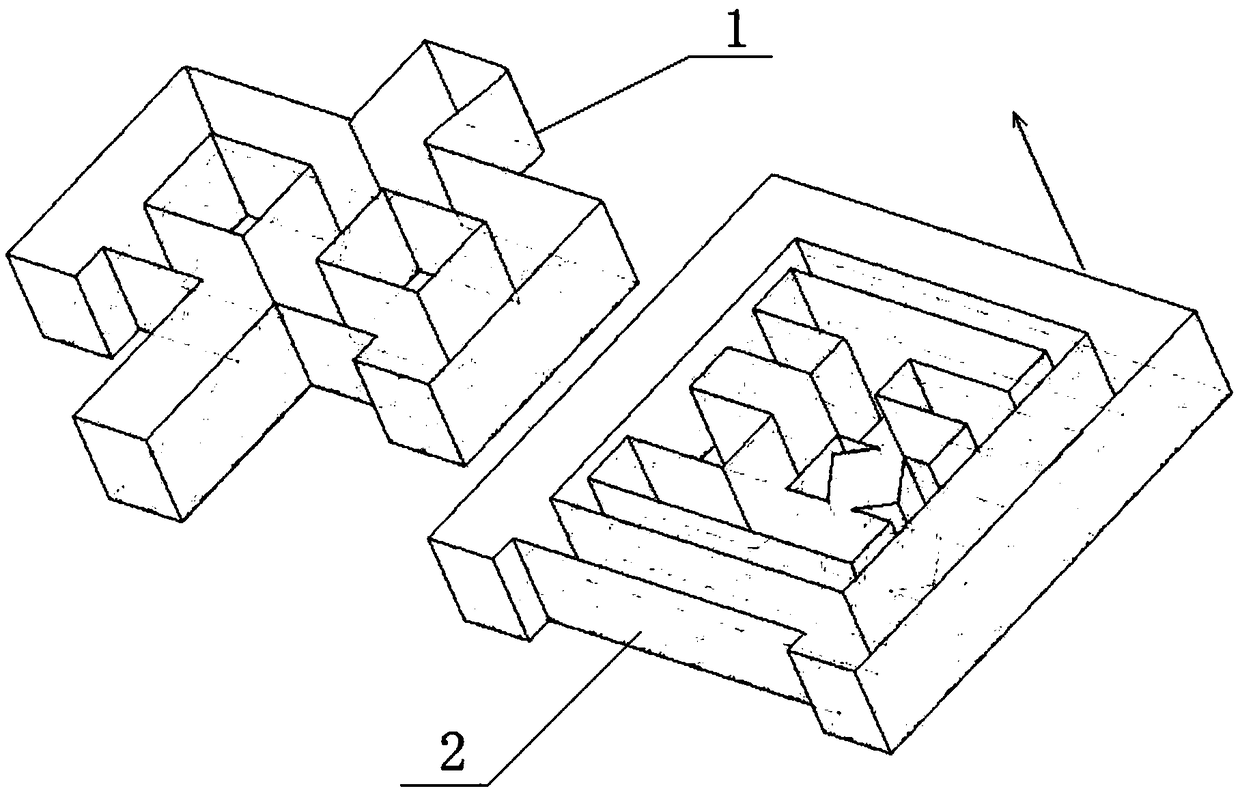

[0040] Luminous characters include font outline 1, light source and panel, among which:

[0041] Font outline 1 structure like figure 2 As shown, it is an internal hollow three-dimensional glyph frame surrounded by plate-shaped materials. The wall thickness of the font outline 1 is 2mm and is made of PMMA; the font outline 1 is provided with a support layer 2 perpendicular to the height direction of the font outline 1 , the support layer 2 is located at the bottom end of the font outline 1, with a thickness of 3 mm; the support layer 2 has a rhombus grid structure, and the side length of each rhombus is 10 mm;

[0042] The light source is an LED lamp, which is directly arranged on the supporting layer 2;

[0043] The panel is a font panel made of PMMA and is located on the light source.

[0044] The specific process flow for preparing the luminous characters is as follows:

[0045] ①. Drawing: Design the size and shape of the luminous characters, and make a wireframe diagr...

Embodiment 2

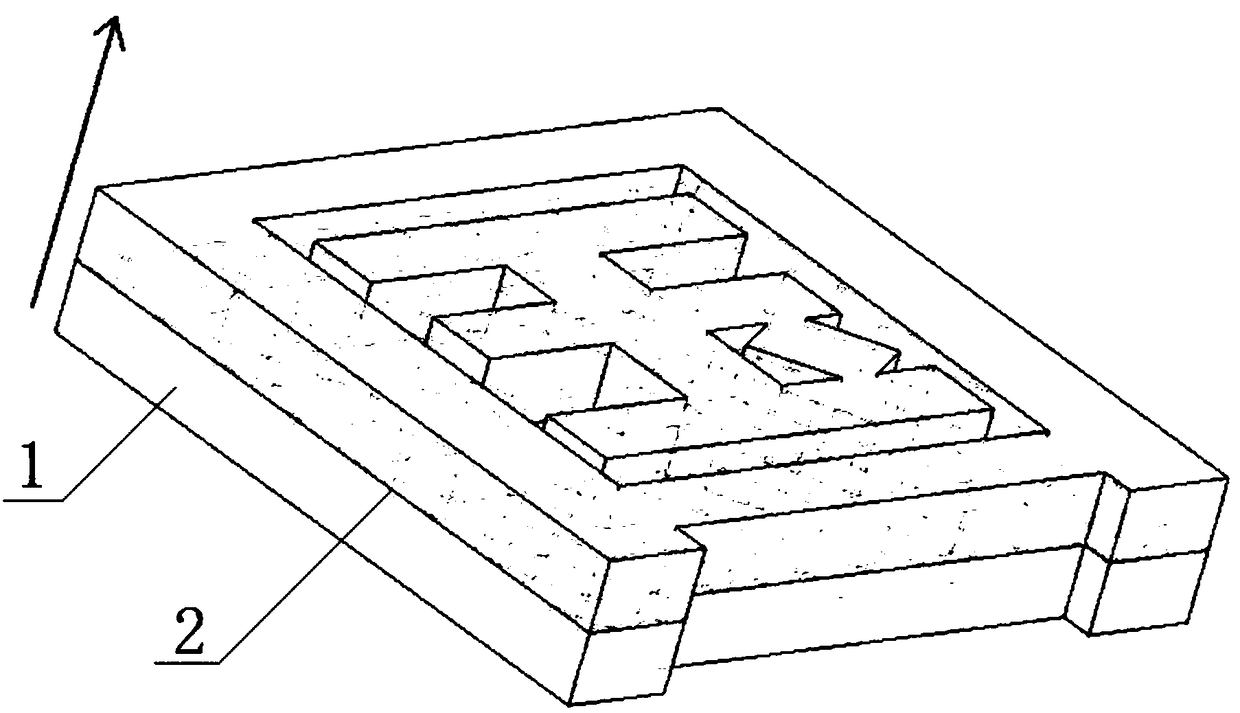

[0050] The difference from Example 1 is: when printing the font outline 1 in step ②, the support layer 2 is printed after printing half the height of the font outline 1, and the structure of the final printed font outline 1 is as follows image 3 As shown, its supporting layer 2 is located in the middle of the font outline 1, such as Figure 4 As shown, the thickness is 0.5mm.

Embodiment 3

[0052] The difference with Example 1 is:

[0053] In step ②, the support layer 2 is a triangular grid structure, the side length of the triangle is 5 mm, and the thickness of the support layer 2 is 15 mm.

[0054] The preparation method of the panel in step ④ is: use an engraving machine to carve the solid panel according to the size of the font outline 1, and stick the solid panel to one end of the font outline 1 after engraving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com