Supercapacitor module set structure

A supercapacitor module and supercapacitor technology, which is applied in hybrid capacitor terminals, hybrid capacitor collectors, multiple hybrid/electric double layer capacitors, etc., can solve problems such as cumbersome installation methods, poor thermal conductivity, and complex circuit structures , to achieve the effects of compact structure, enhanced heat dissipation, and good expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

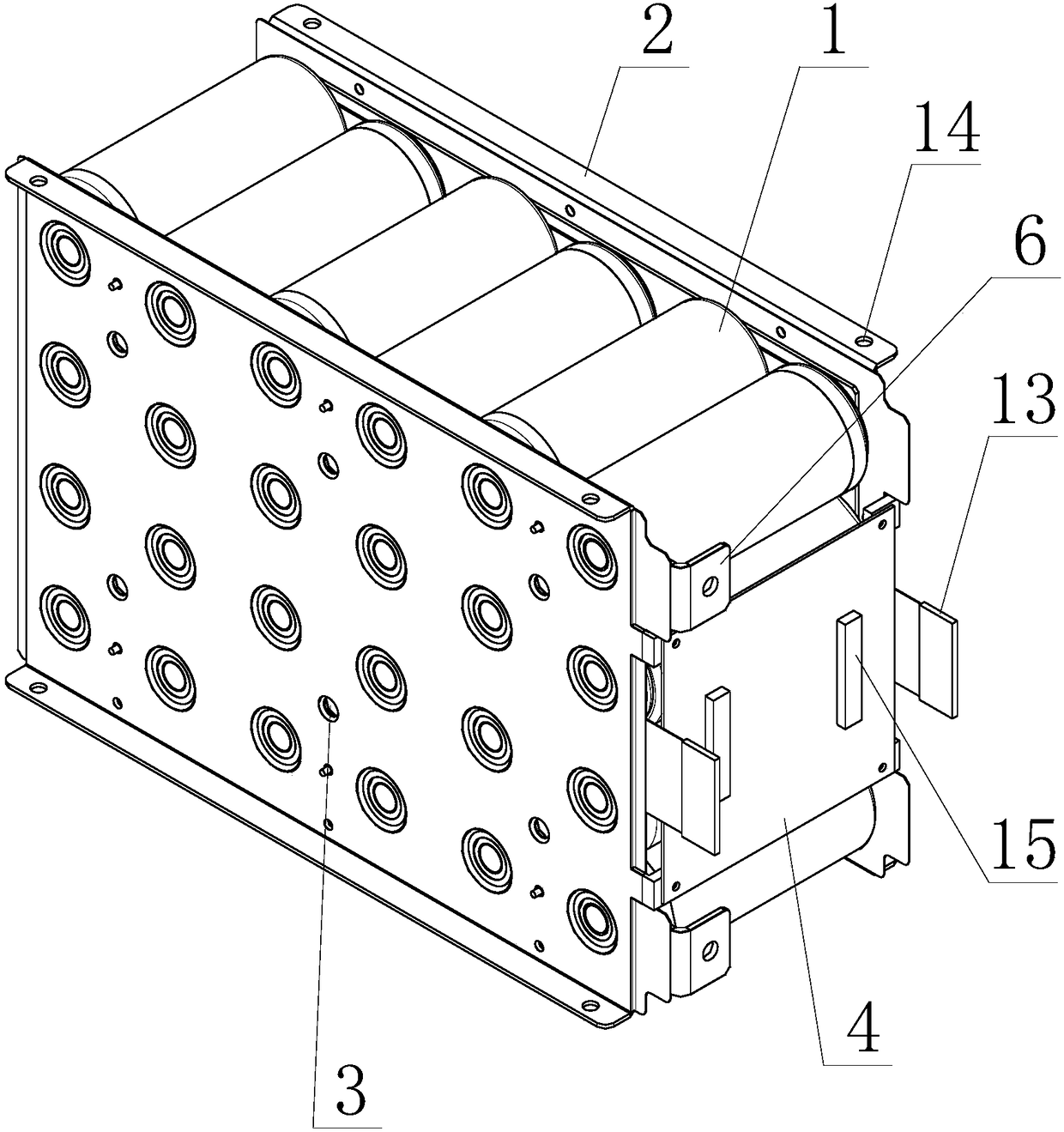

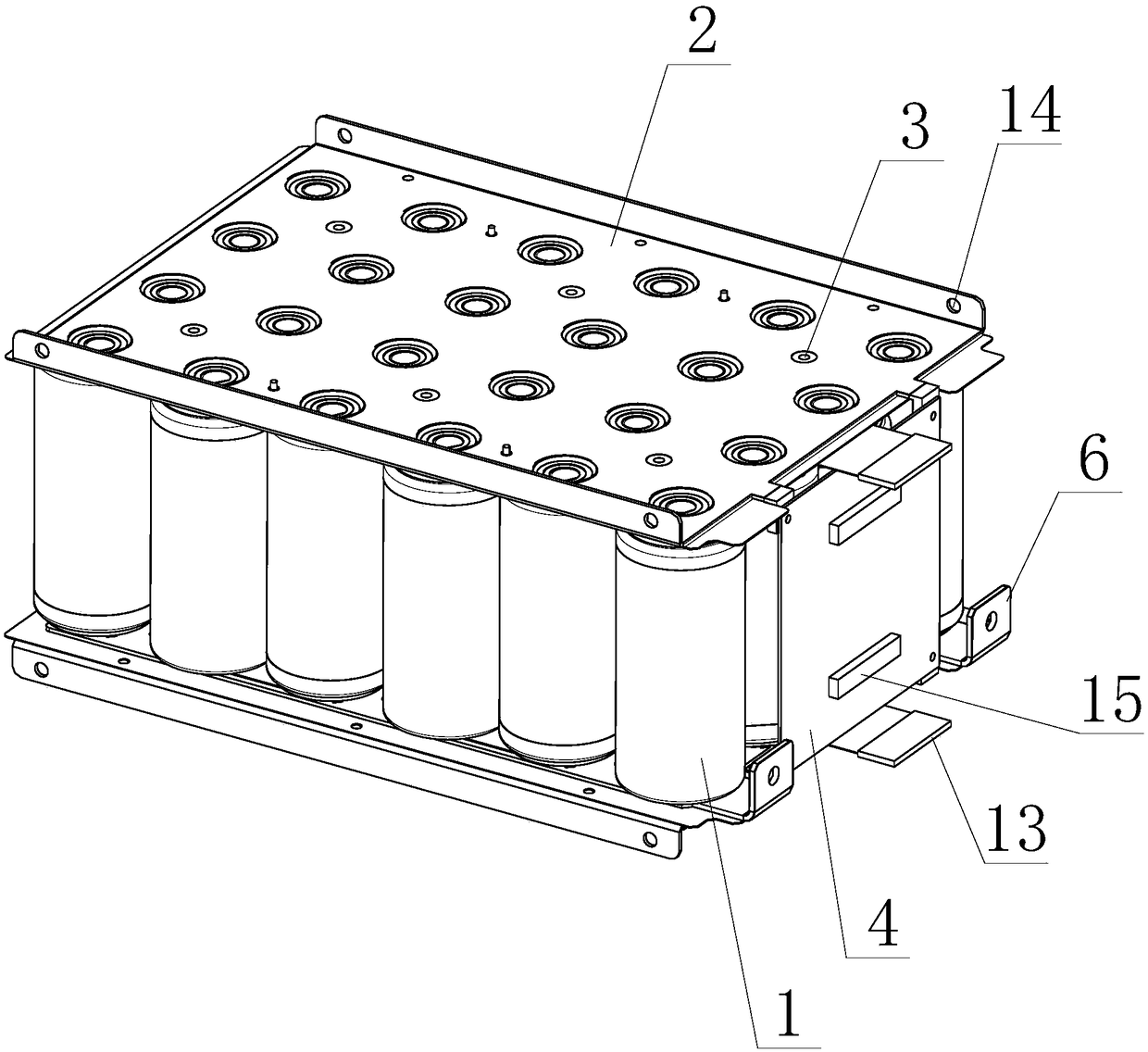

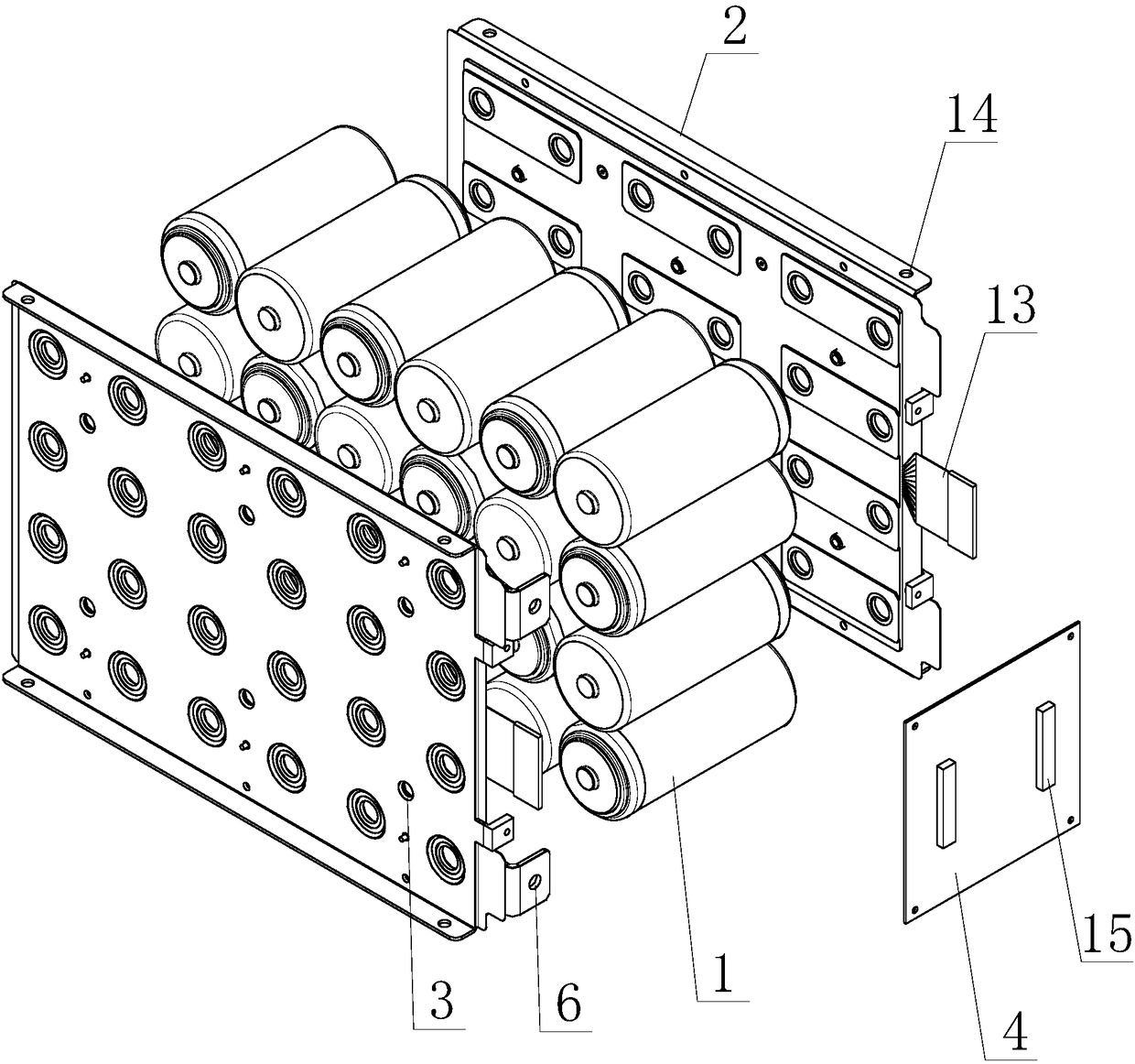

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] Such as Figure 1~3 The structure of the supercapacitor module shown includes a plurality of supercapacitor cells 1 arranged in parallel, two laminated busbars 2 fixed at both ends of the supercapacitor cell 1 and used to protect all supercapacitors in the monitoring module. The protection monitoring circuit 4 of the monomer 1 . The laminated busbar 2 integrates the busbar, frame, ground insulation support, and the connection wire lead-out function of the protection monitoring circuit 4, and also has the functions of current conduction, heat conduction, lead-out protection monitoring circuit connection wire, frame insulation and support frame. Function, the protection monitoring circuit is integrated into a PCB board, and at the same time provides the protection and detection functions of all monomers. The supercapacitor unit 1 is placed vertically or horizontally,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com