Metasurface-based convex conformal Gregory antenna

A Gregorian and metasurface technology, applied to antennas, electrical components, waveguide horns, etc., can solve problems such as large phase compensation errors, phase error increases, and large phase errors, achieving accurate phase compensation, simple structure, and easy Processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

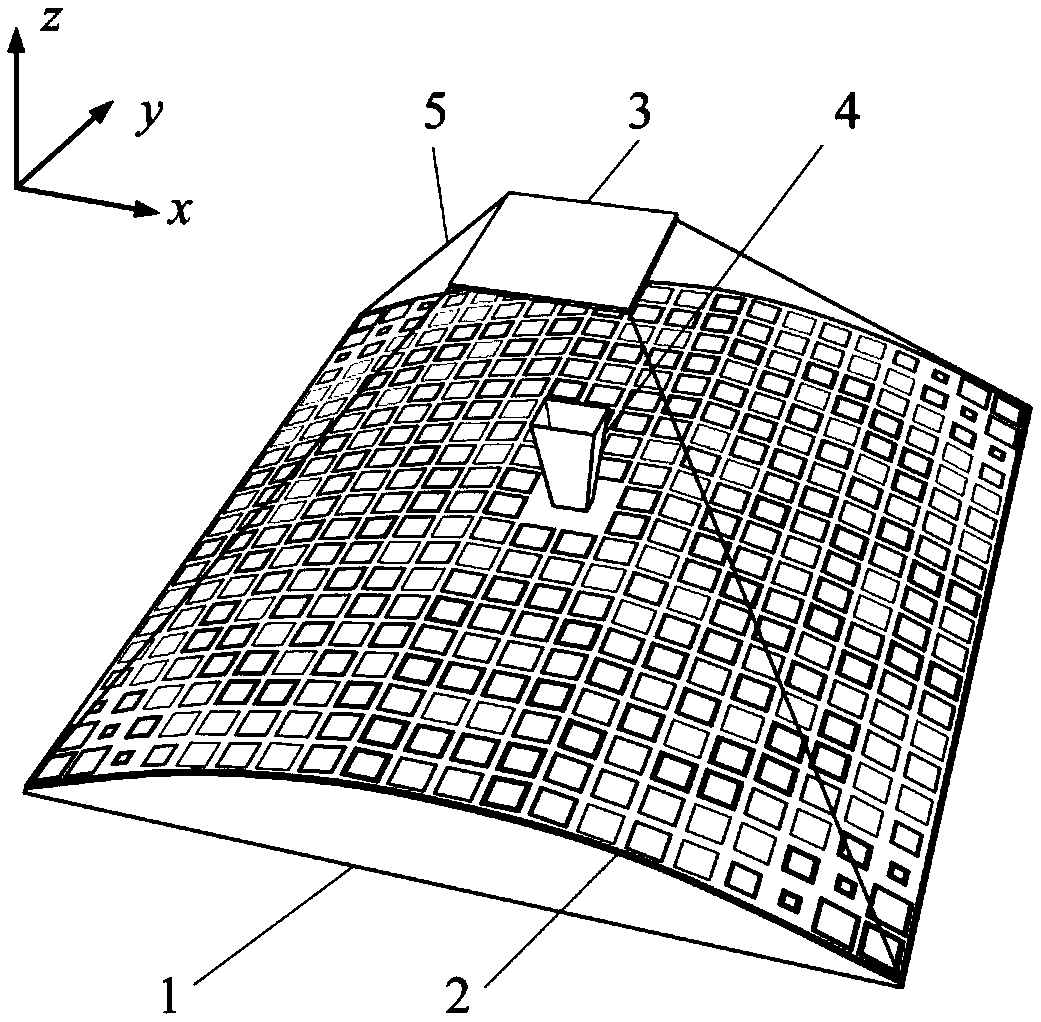

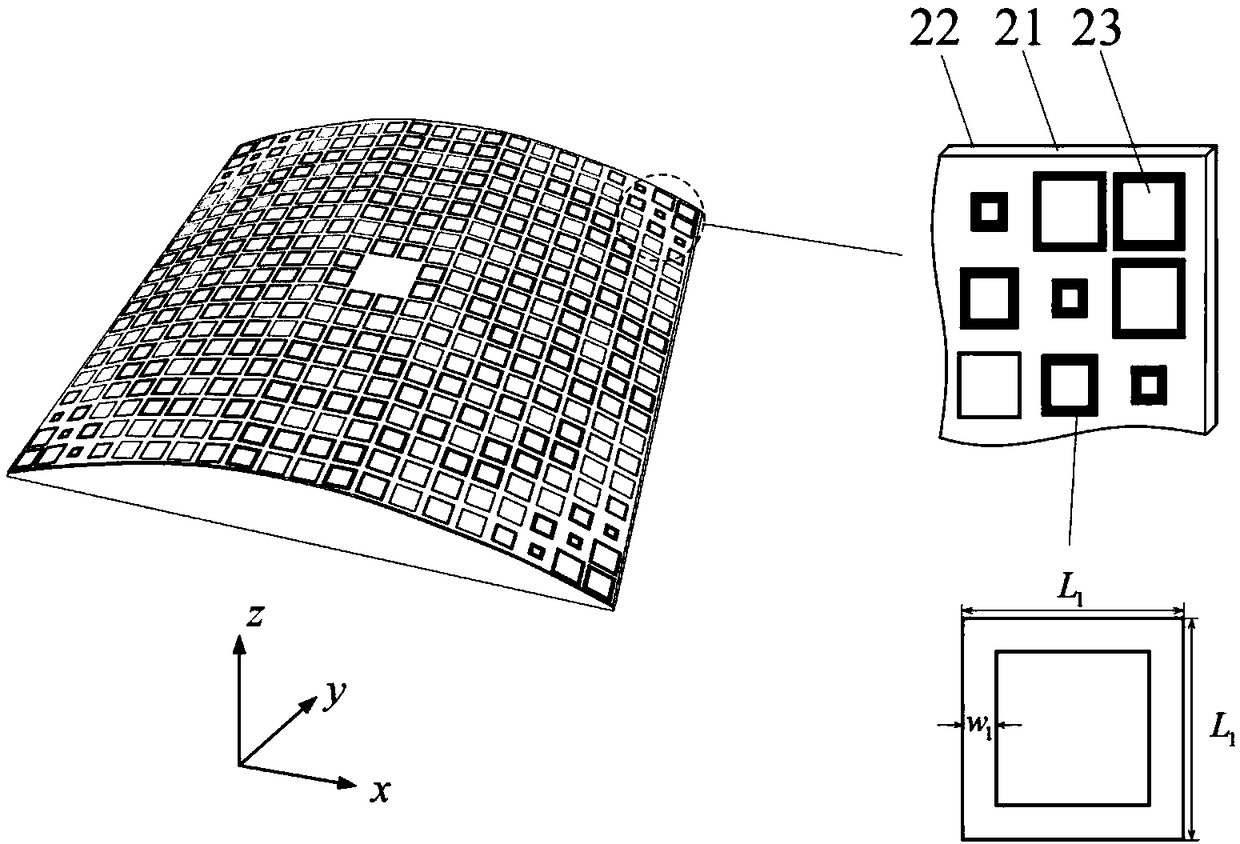

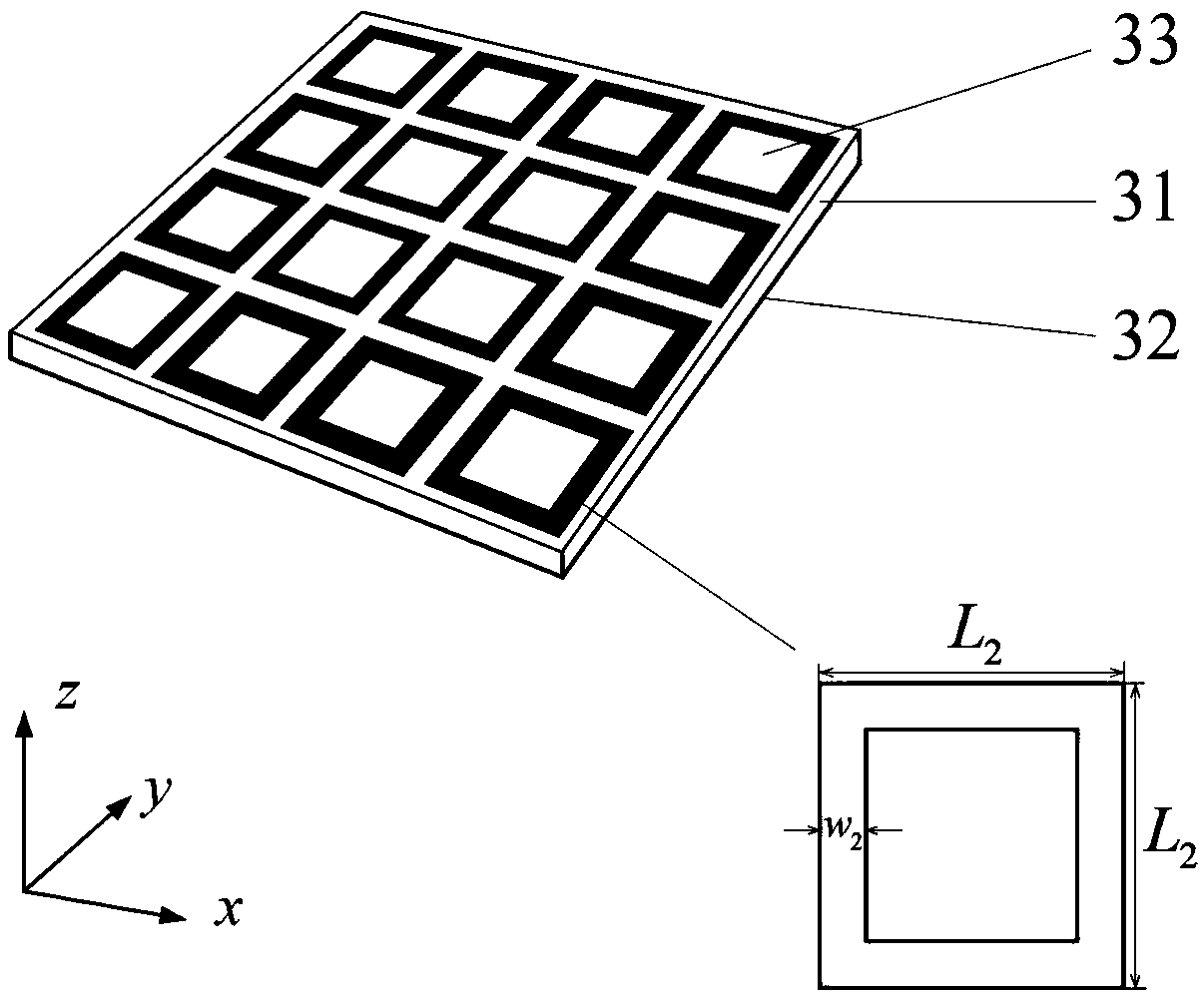

[0036] refer to figure 1 , the present invention includes a carrier 1 , a primary reflector 2 , a secondary reflector 3 , a feed source 4 and a supporting structure 5 . The carrier 1 is located at the bottom of the overall structure of the antenna, the main reflector 2 is conformally inlaid on the upper surface of the carrier 1, the feed source 4 is located in the central hollow position of the carrier 1 and the main reflector 2, and the secondary reflector 3 is located on the front of the feed source 4. Above, it is connected with the main reflector 2 through a supporting structure.

[0037]The carrier 1 adopts a convex structure, and the main reflector 2 is conformal to the carrier 1. The center of the conformal structure is hollowed out, and a feed source 4 is installed in the hollowed out position. The feed source 4 adopts a pyramidal horn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com