Semiconductor laser based on distributed phase compensation technology

A phase compensation and semiconductor technology, which is applied in the field of optoelectronics, can solve problems such as poor single-mode characteristics of lasers and unstable output modes of lasers, and achieve the effect of improving lasing modes, increasing energy utilization and output power, and realizing phase compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

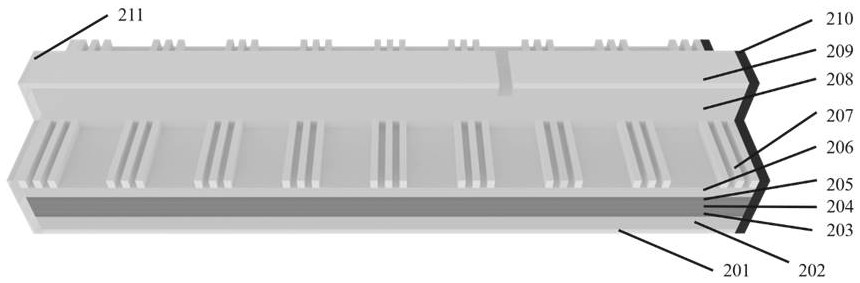

[0036] Taking the operating wavelength within the range of 1550nm as an example, a semiconductor laser based on distributed phase compensation technology provided by the present invention is described below, and the preparation process of the semiconductor laser is specifically as follows:

[0037] (1) First, the epitaxial material is manufactured by MOVPE technology, and the n-type InP buffer layer (thickness 200nm, doping concentration about 1.1x10 18 cm -2 ), non-doped lattice-matched InGaAsP confinement layer (thickness 100nm), strained InGaAsP multi-quantum well layer (fluorescence wavelength 1.52 microns, 7 quantum wells: well width 8nm, 0.5% compressive strain, barrier width 10nm, lattice matching material), p-type lattice matching InGaAsP (thickness 100nm, doping concentration about 1.1x10 17 cm -2 ) on the confinement layer and corrosion barrier layer respectively;

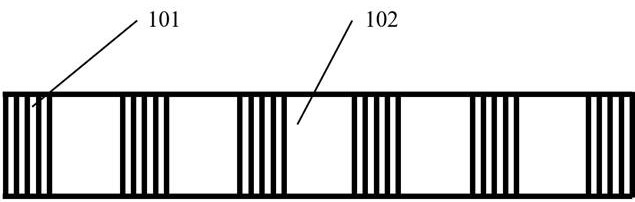

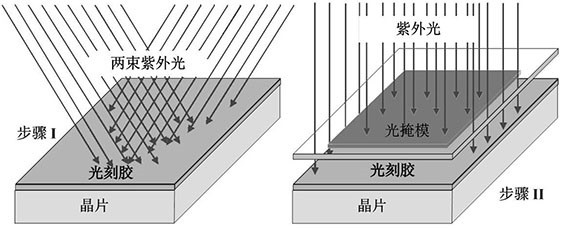

[0038] (2) Design and manufacture the sampling grating pattern of semiconductor lasers based on dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com