Preparation method of porous platinum breathable sheet for nuclear battery ventilation window

A technology of ventilation window and nuclear battery, applied in the field of metal powder metallurgy, can solve the problems of low production efficiency and high production cost, and achieve the effect of good connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

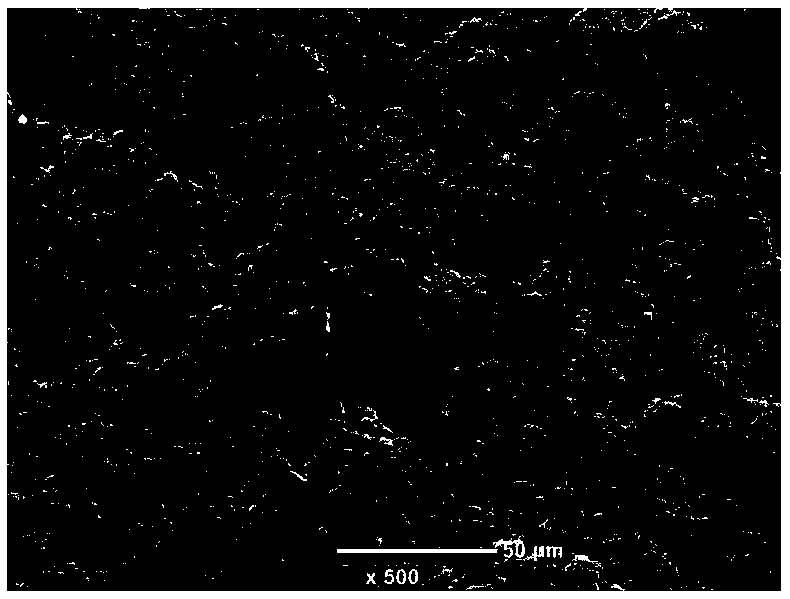

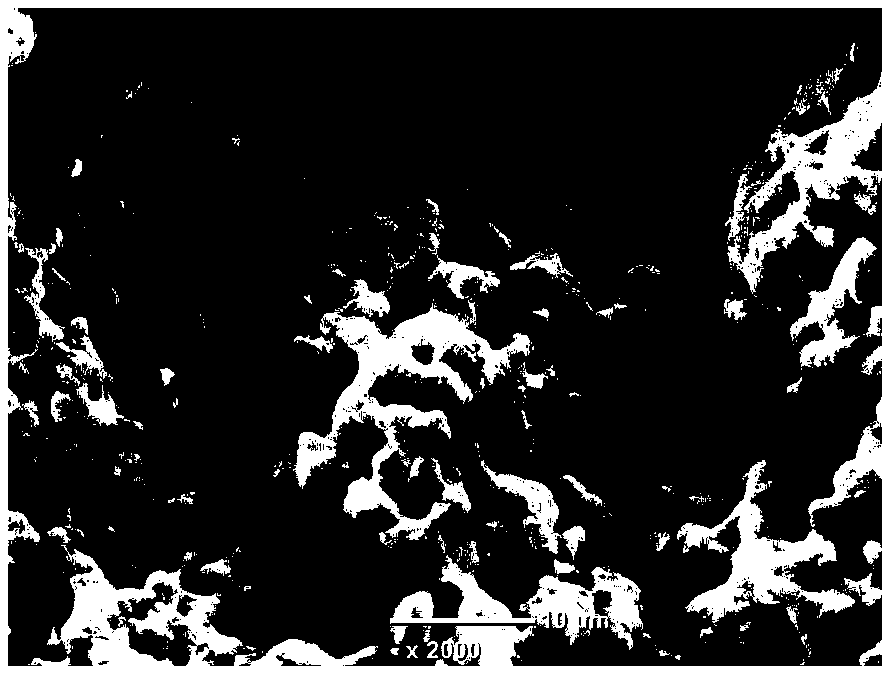

Image

Examples

Embodiment 1

[0037] In this example, platinum powder is selected as the raw material, and the porosity is controlled at 20% by controlling the ratio of the actual filling powder volume to the total volume of the mold filling area, and the secondary sintering temperature is set at 1200°C to obtain porous platinum with extremely small air permeability Breathable sheet. Its specific process includes the following steps:

[0038] Step 1: Determine the porosity and particle size of the powder:

[0039] The particle size of the powder has two different particle sizes in proportion;

[0040] The determined porosity is 20%; the determined two different particle sizes are 300 mesh and 500 mesh respectively; the 300 mesh platinum powder:500 mesh powder=1.216:3.755; the ratio is the mass ratio.

[0041] When determining the porosity and the particle size of the powder, the relationship between the porosity of the porous platinum air-permeable sheet and the particle size of the powder should satisfy...

Embodiment 2

[0052] In this example, platinum powder is selected as the raw material, and the porosity is controlled at 21% by controlling the ratio of the actual filling powder volume to the total volume of the mold filling area, and the secondary sintering temperature is set at 1200°C to obtain porous platinum with extremely small air permeability Breathable sheet. Its specific process includes the following steps:

[0053] Step 1: Determine the porosity and particle size of the powder:

[0054] The particle size of the powder has two different particle sizes in proportion;

[0055] The determined porosity is 21%; the two determined particle sizes are 300 mesh and 500 mesh respectively; the 300 mesh platinum powder:500 mesh powder=1.216:3.755; the ratio is the mass ratio.

[0056] When determining the porosity and the particle size of the powder, the relationship between the porosity of the porous platinum air-permeable sheet and the particle size of the powder should satisfy:

[0057...

Embodiment 3

[0065] In this example, platinum powder is selected as the raw material, and the porosity is controlled at 22% by controlling the ratio of the actual filling powder volume to the total volume of the mold filling area, and the secondary sintering temperature is set at 1220°C to obtain porous platinum with extremely small air permeability Breathable sheet. Its specific process includes the following steps:

[0066] Step 1: Determine the porosity and particle size of the powder:

[0067] The particle size of the powder has two different particle sizes in proportion;

[0068] The determined porosity is 22%; the two different particle sizes determined are 300 mesh and 500 mesh respectively; the 300 mesh platinum powder:500 mesh powder=1.216:3.755; the ratio is the mass ratio.

[0069] When determining the porosity and the particle size of the powder, the relationship between the porosity of the porous platinum air-permeable sheet and the particle size of the powder should satisfy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com