Multi-station machine tool for processing wrenches

A multi-station, machine tool technology, applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low efficiency, time-consuming and labor-intensive processing of wrenches, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

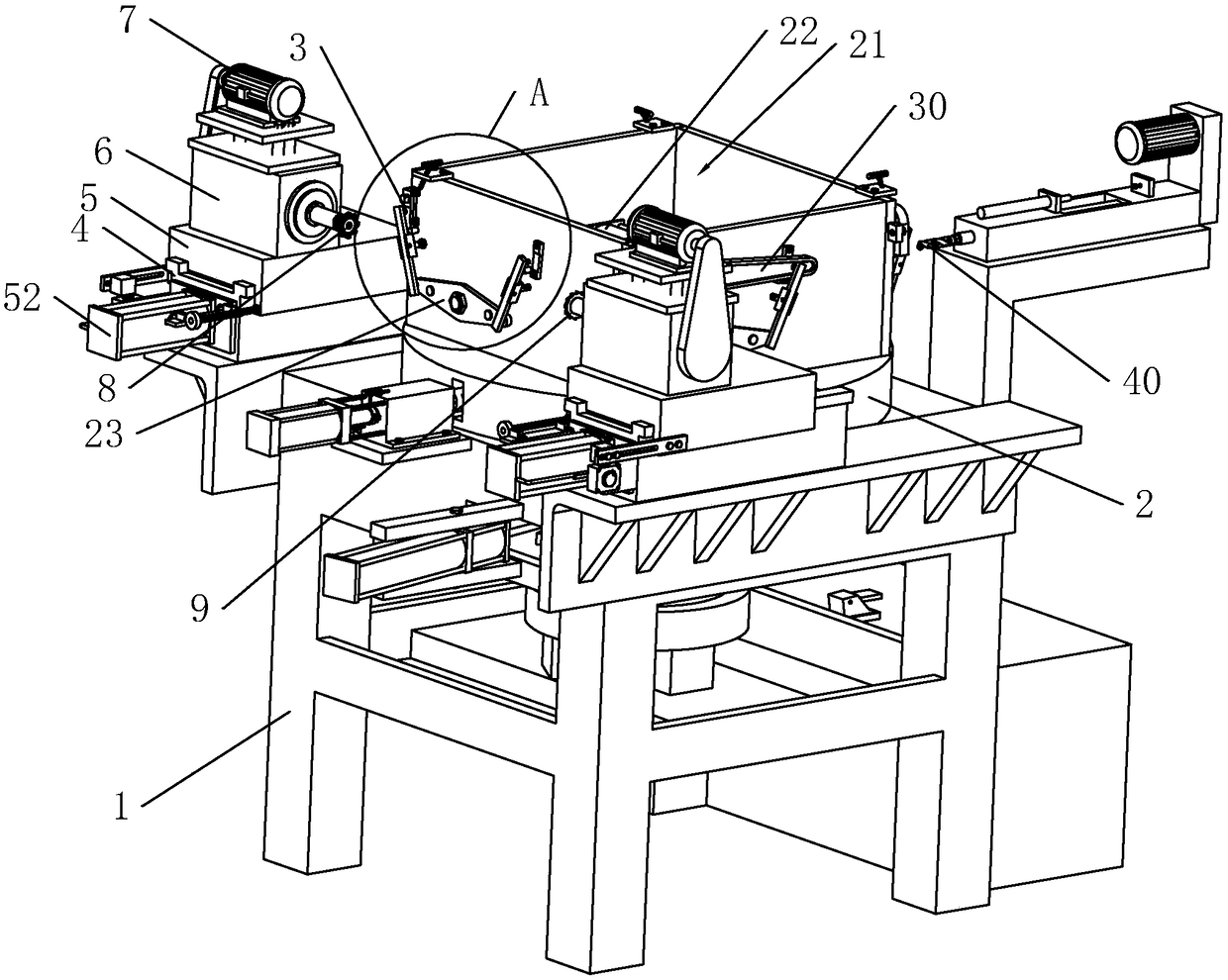

[0044] Such as figure 1 As shown, a multi-station machine tool for processing wrenches, including a frame 1, a turntable 2, a clamping mechanism 3, a guide rail 4, a sliding plate 5, a transmission gearbox 6, a driving motor 7, a face milling cutter 8, a groove Milling cutter 9, drill bit 40, turntable 2 are connected on the frame 1 in rotation, and pass drive mechanism 10 (see Figure 4 ) to drive; the turntable 2 mainly relies on its own rotation to drive the blank wrench 30 to move from the previous station to the next station, and the clamping mechanism 3 is used to fix the blank wrench 30 on the turntable 2 .

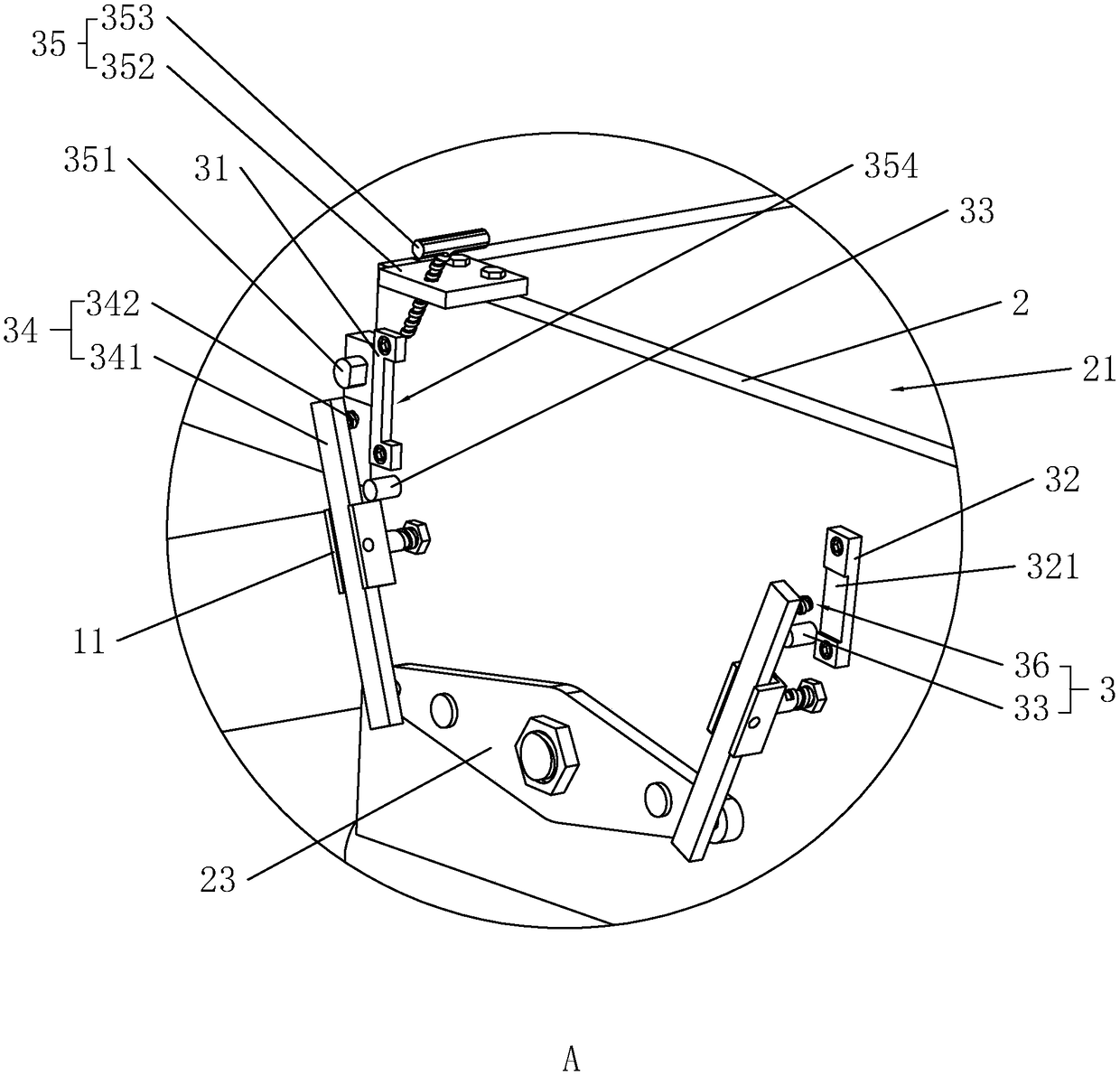

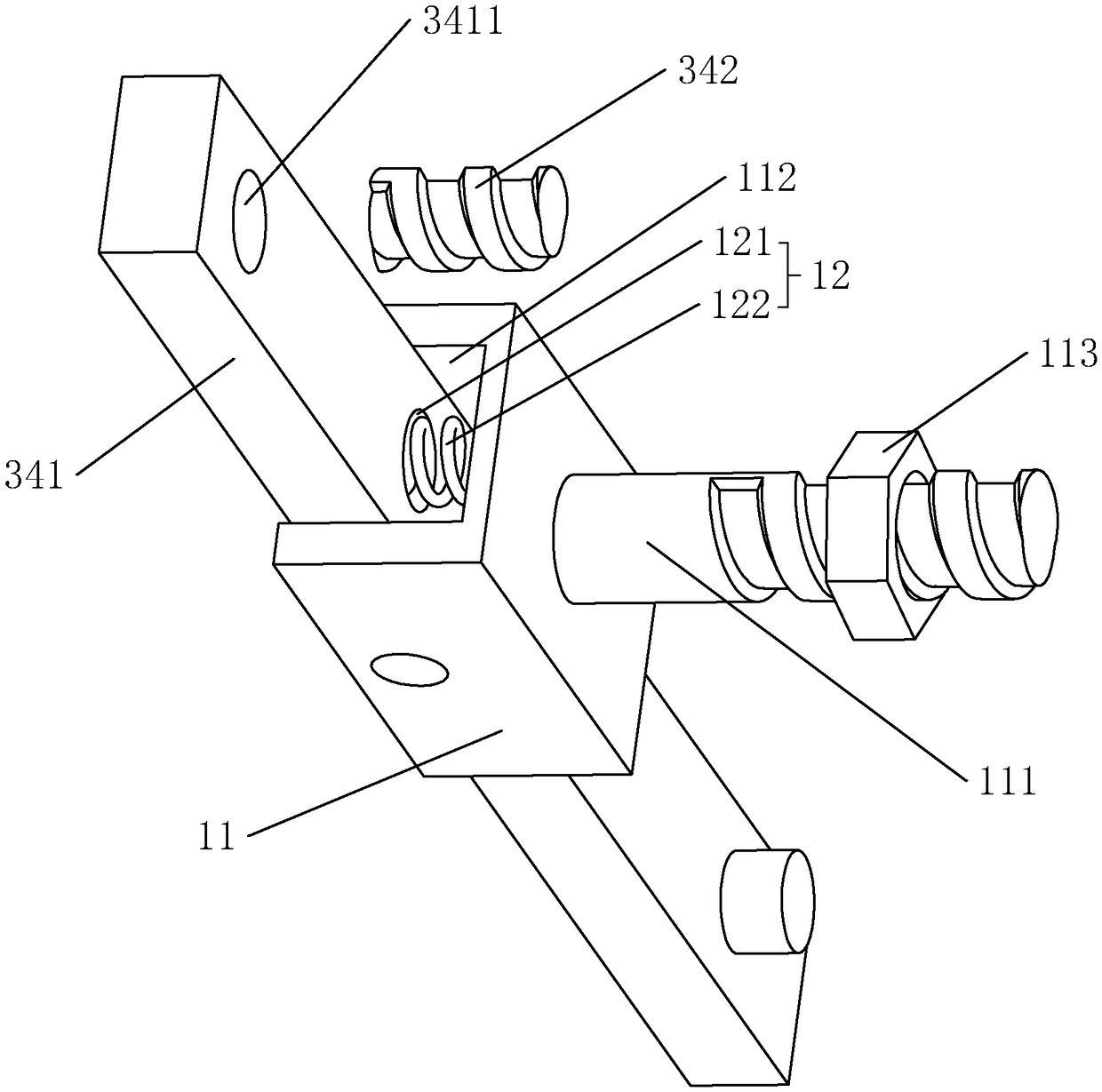

[0045] Such as figure 2 As shown, the clamping mechanism 3 includes a first positioning block 31, a second positioning block 32, two support columns 33, two pressing blocks 34, and a reinforcement assembly 35, and the first positioning block 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com