Line side automatic tooling three-dimensional switching and storing device

A storage device and automatic technology, applied in storage devices, transportation and packaging, conveyors, etc., can solve problems such as slow switching of tooling, small space in the production area, and single storage method, so as to reduce utilization rate, reduce capital pressure, and invest low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

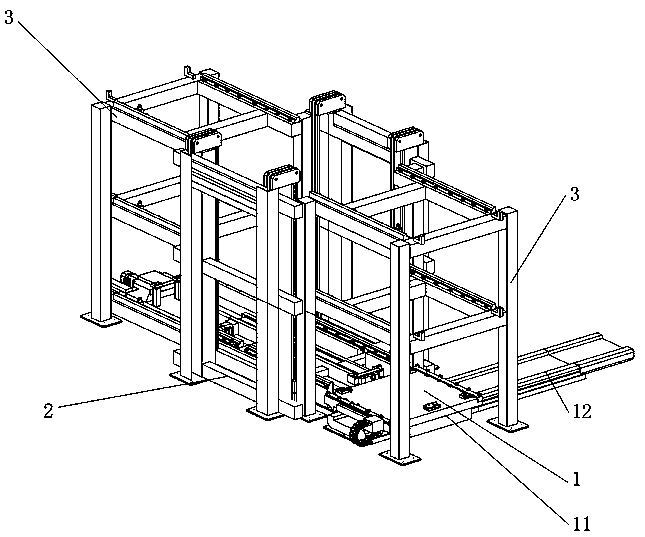

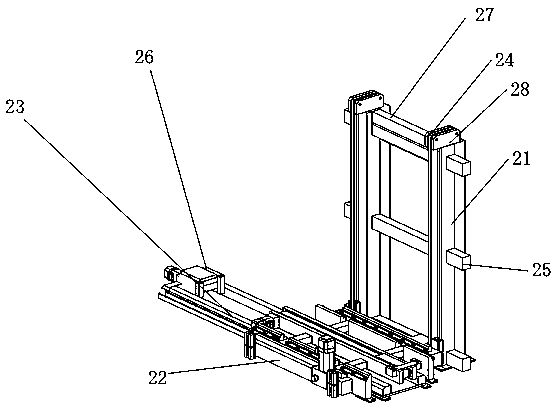

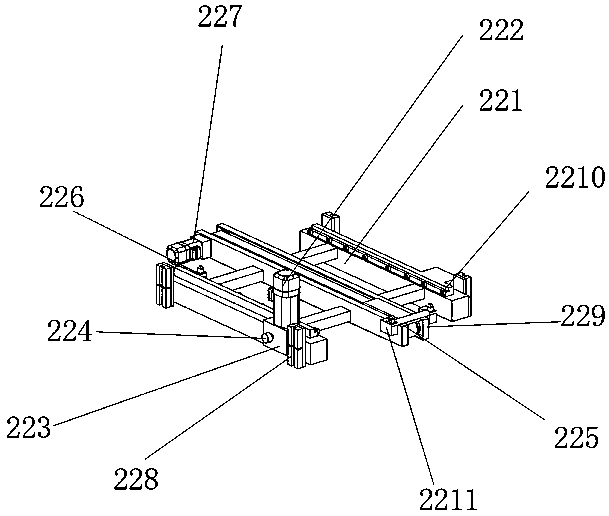

[0016] In a preferred embodiment of the present invention, in order to solve the above-mentioned technical problems, the present invention adopts a three-dimensional switching and storage device for automatic tooling at the edge of the line, please refer to figure 1 , including a servo tooling positioning platform and a track 1, a lifting and traversing system 2, and a three-dimensional tooling warehouse 3. It is characterized in that the servo tooling positioning platform and track 1 include a tooling positioning platform 11 and a track 12, positioning tooling fixtures and conveying Tooling fixtures to production stations; the lifting and lateral movement system 2 can move up and down and laterally to complete the scheduling and lifting of tooling fixtures; the tooling stereoscopic warehouse 3 is a frame structure, and the servo tooling positioning platform and track 1 and lifting and traverse system 2 are all installed on the tooling three-dimensional warehouse structure.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com