Edible oil bottling machine

An oil bottle and oil filling technology, applied in the field of edible oil filling equipment, can solve the problems of inconsistent oil quantity, high labor cost input, low work efficiency, etc., and achieve the effects of avoiding direct contact, reducing labor input, and preventing artificial pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

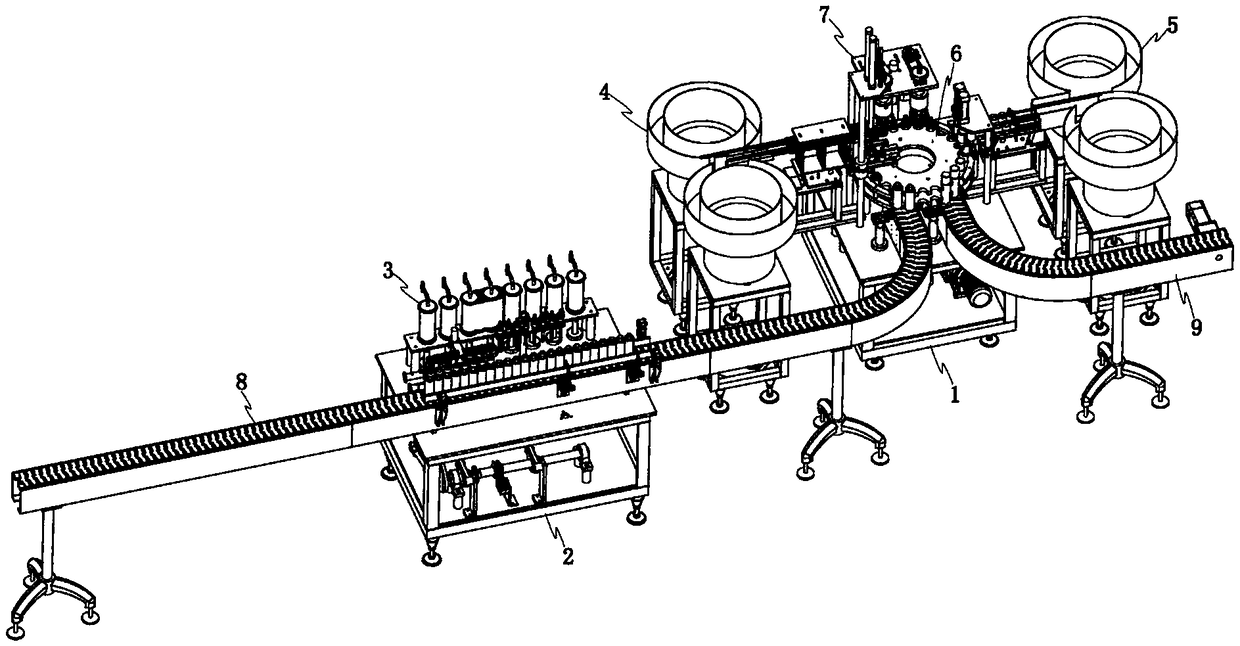

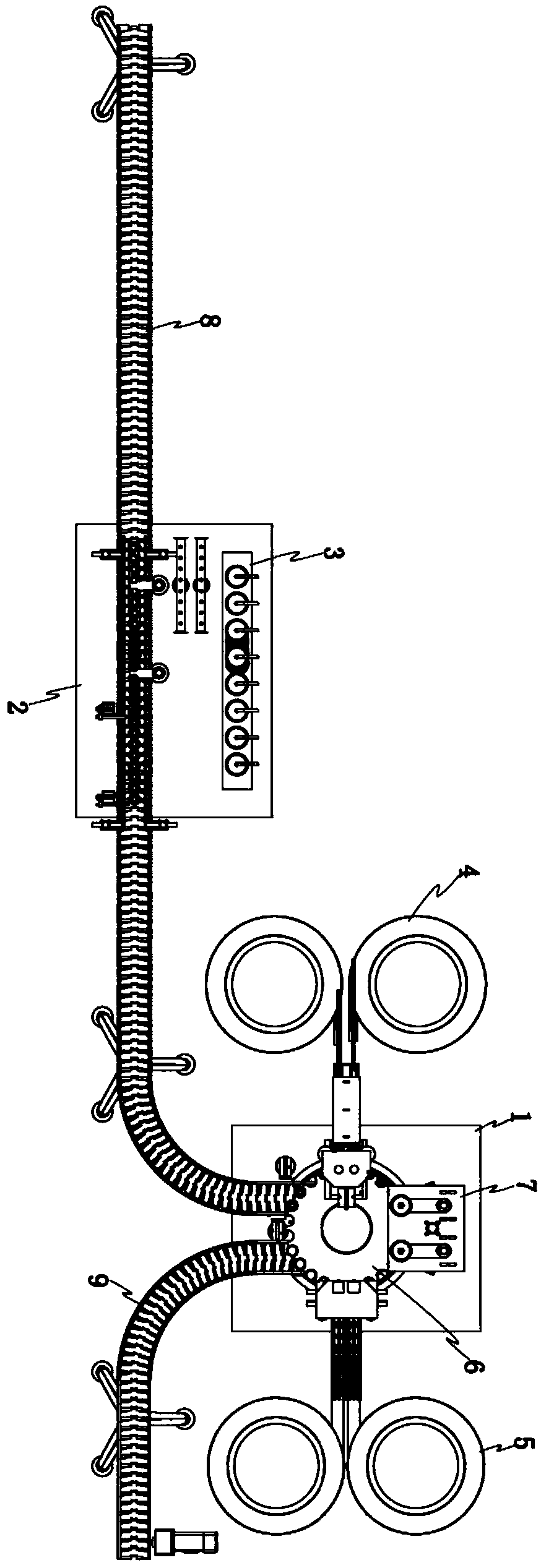

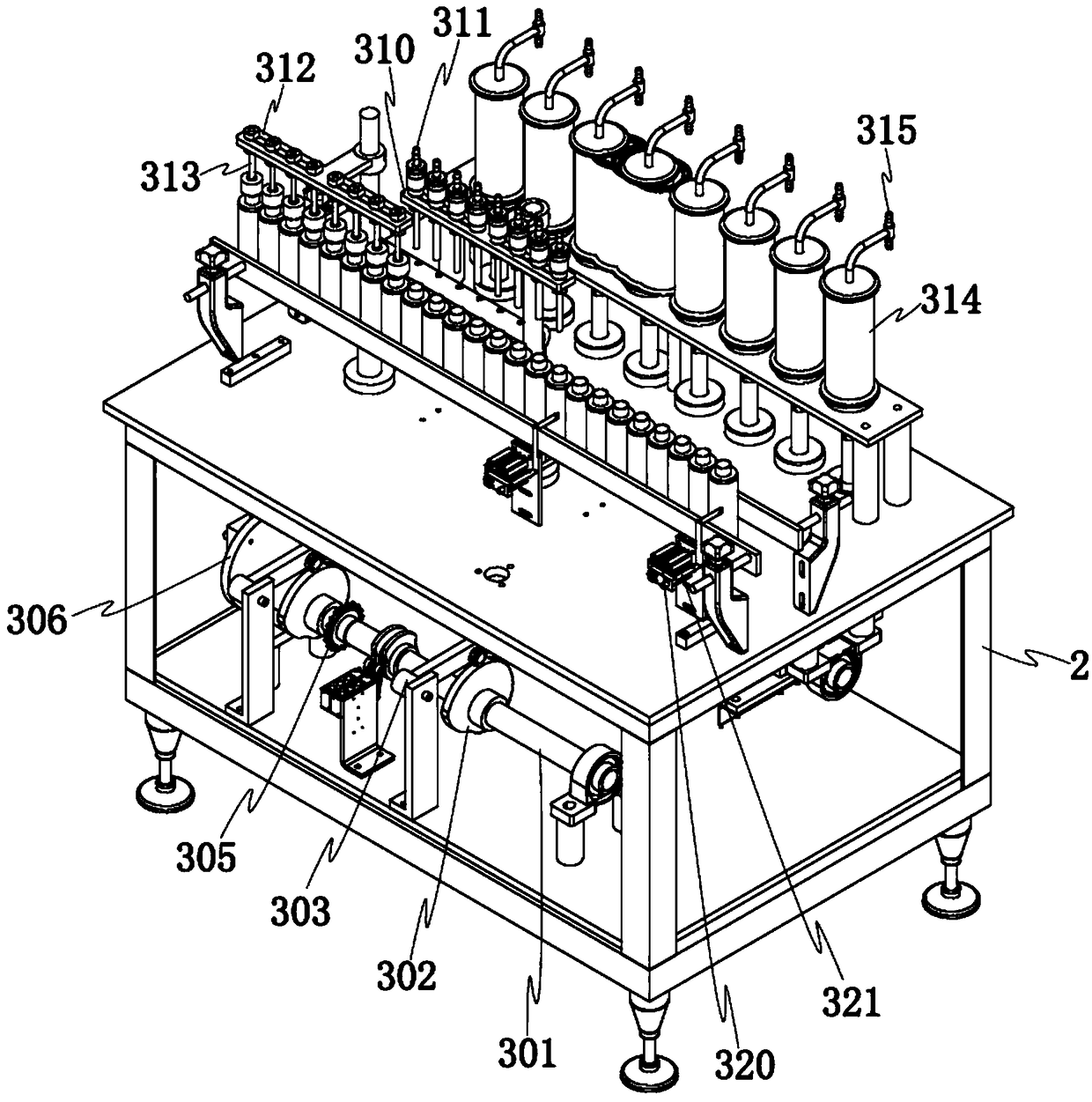

[0038] The filling machine is composed of a dust removal and oil filling mechanism 3, a turntable mechanism 6, an inner cover input capping mechanism 4, an inner cover tightening mechanism 7, an outer cover input fastening mechanism 5, an input belt 8 and an output belt 9. The belt 8 inputs the empty bottles one by one to the dust removal and oil filling mechanism 3 of the second table body 2, the driving motor I317 of the dust removal and oil filling mechanism 3 drives the gearbox 318 to run, and the gearbox 318 drives the first rotating shaft 301 to rotate through the sprocket transmission , so as to drive the cam I302 on the first rotating shaft 301 and the eccentric wheel 306 at the end of the shaft to rotate, and the rotating cam I302 drives the hinged rod 303 adjoined to it to float up and down, thereby driving the lifting rod I304 to move up and down, and the same eccentric wheel 306 The rotation drives the second rotating shaft 307 to rotate back and forth within a cert...

Embodiment 2

[0040] When the bottle filled with edible oil is conveyed to the turntable mechanism 6 by the input belt 8, the drive motor II 601 of the turntable mechanism 6 drives the rotating shaft 603 at the top of the gearbox 602 to rotate, and the rotating rotating shaft 603 drives the double turntable 604 to rotate, And the bottle body clamping groove 605 on the edge of the rotating double turntable 604 snaps in the empty bottles on the input belt 8 one by one, and drives the bottle body to do the disk body rotation movement. The driving motor II601 stops rotating, and the vibrating plate I402 of the inner cap input and capping mechanism 4 outputs the inner bottle caps one by one to the conveyor frame I403, and the inner bottle caps are arranged in sequence on the conveyor frame I403 and transported to the front end, and then start The capping drive cylinder 405 is driven by the capping drive cylinder 405 to drive the capping rod 406 to press down the inner bottle cap at the front end ...

Embodiment 3

[0042]After the placement of the inner bottle cap and the tightening of the bottle mouth are completed, when the bottle body rotates and moves under the drive of the turntable mechanism 6 to directly below the outer cap input fastening mechanism 5, the driving motor II 601 stops rotating, and the outer cap input fastening mechanism 5 The vibrating plate Ⅱ502 transports the outer bottle caps to the conveyor frame Ⅱ503 in sequence, and the outer bottle caps are arranged and moved forward on the conveyor frame Ⅱ503 in sequence. When the outer bottle caps move to the front end of the conveyor frame Ⅱ503, the driving cylinder Ⅱ509 is started. Drive cylinder Ⅱ 509 to drive the cover piece 508 to retract, so that the outer bottle cap on the conveyor frame Ⅱ 503 moves forward to the crimping frame body 504, and the crimping cylinder 505 at the top of the crimping frame body 504 is started, and the crimping block 506 is driven by the crimping cylinder 505 Move, press the outer bottle ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap