Electric leakage test method

A test method, a technology to be tested, applied in circuits, semiconductor/solid-state device testing/measurement, electrical components, etc., capable of solving problems such as failure analysis effects, loss of metal wires, and damage to the surface of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the leakage test method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

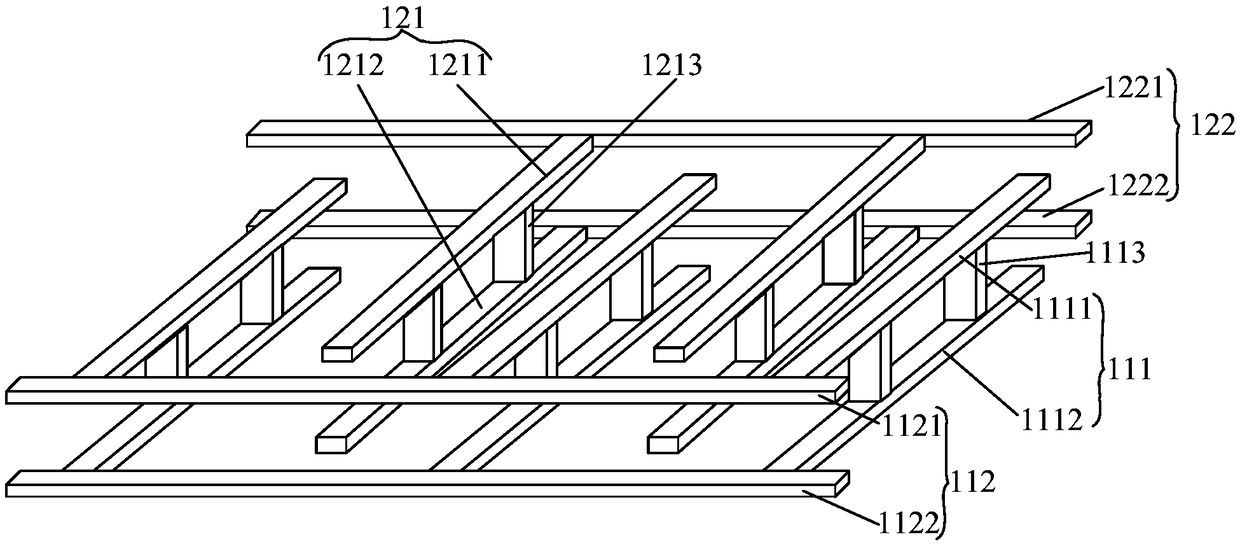

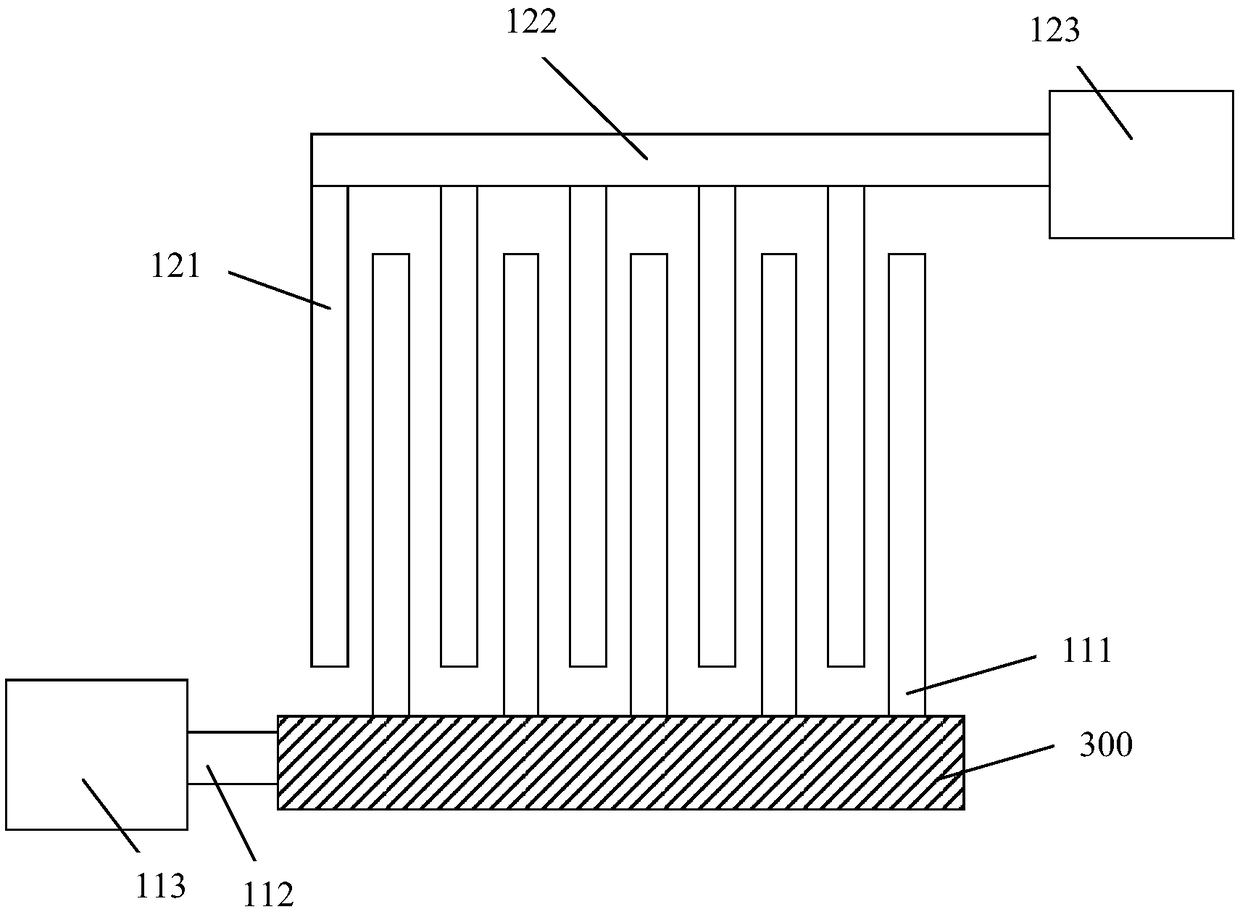

[0019] Please refer to Figure 1 to Figure 4 , is a structural schematic diagram of a leakage test process according to a specific embodiment of the present invention.

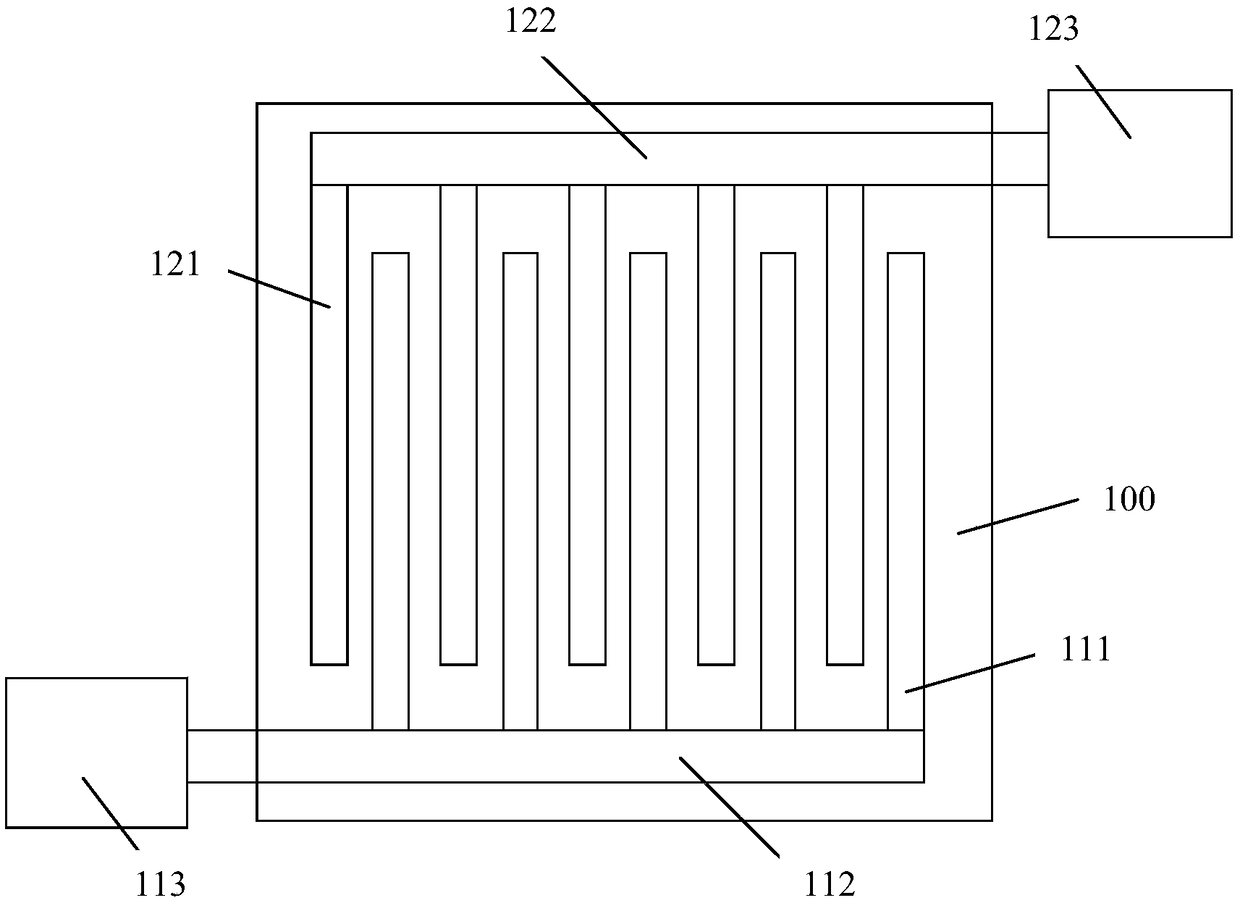

[0020] Please refer to figure 1 , providing a sample to be tested, figure 1 is a top perspective view of the sample to be tested.

[0021] The sample to be tested includes an insulating layer 100, and a leakage test structure is formed in the insulating layer 100. The leakage test structure includes: a first comb-shaped metal wire, a second comb-shaped metal wire, and the first comb-shaped metal wire The line includes a plurality of first comb-toothed metal lines 111 arranged in parallel, and the second comb-shaped metal line includes a plurality of second comb-toothed metal lines 121 arranged in parallel, and the first comb-tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com