Control system based on multi-axis synchronous movement of EtherCAT bus, for laser cutting head

A laser cutting head, multi-axis synchronization technology, applied in the field of laser cutting head control system, can solve the problems of reducing the processing efficiency of the whole set of equipment, increasing the processing time of workpieces, etc., to achieve the effect of fast processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

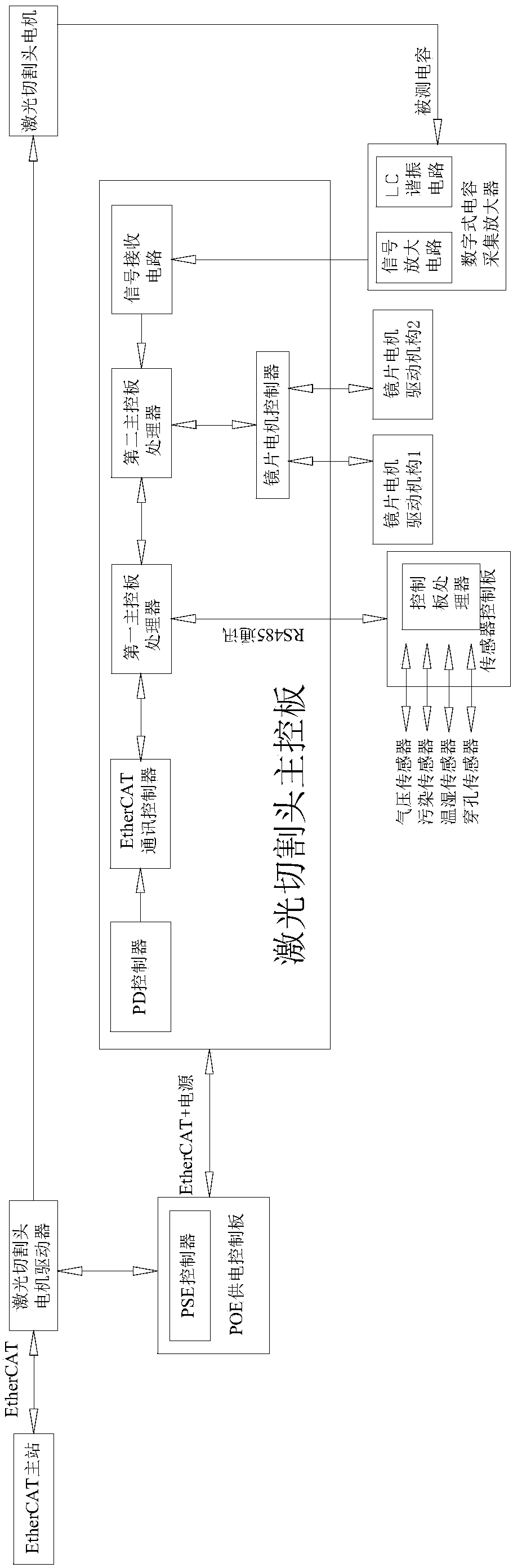

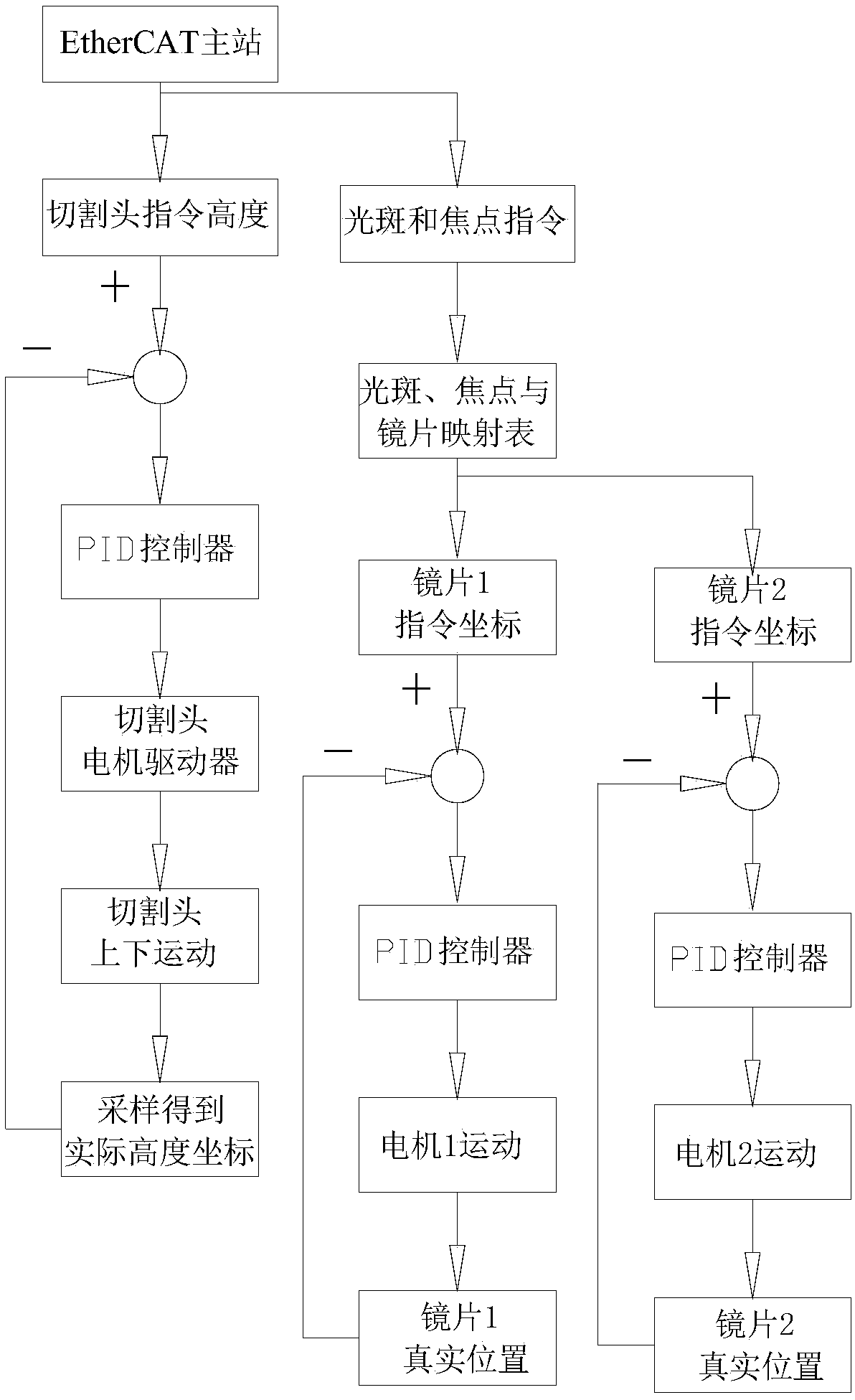

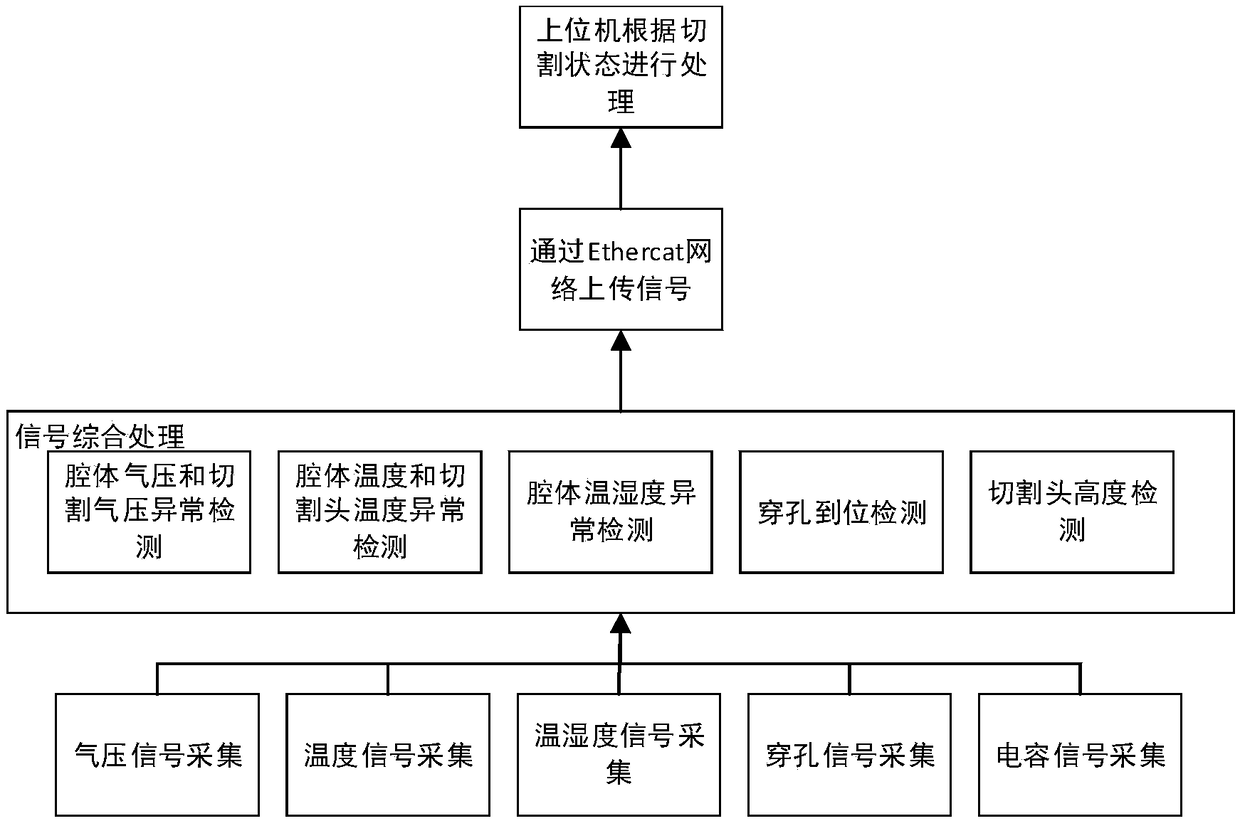

Method used

Image

Examples

Embodiment 1

[0060] Example 1, such as Figure 5 As shown, according to the needs of processing the workpiece 101 and the workpiece 102, a positive lens is arranged in the upper lens fixing mechanism 3, a negative lens is arranged in the lower lens fixing mechanism 4, and a positive lens is arranged in the focusing optical element fixing mechanism 5.

[0061] When processing the workpiece 101, first, the sensor control board detects whether the working environment data is qualified; secondly, according to the workpiece 101, the EtherCAT master station retrieves the height data of the laser cutting head and the process parameters of the light spots and focus data of the upper and lower lenses, and sends instructions respectively Give the laser cutting head motor control module and the laser cutting head main control board; then, the laser cutting head motor control module moves the position of the nozzle assembly 11 of the laser cutting head to the distance d from the upper surface of the wo...

Embodiment 2

[0064] Example 2, such as Figure 6 As shown, according to the needs of processing workpieces 201 and 202, a positive lens is set in the upper lens fixing mechanism 3, a positive lens is set in the lower lens fixing mechanism 4, and a positive lens is set in the focusing optical element fixing mechanism 5.

[0065] When processing the workpiece 201, first, the sensor control board detects whether the working environment data is qualified; secondly, according to the workpiece 201, the EtherCAT master station retrieves the height data of the laser cutting head and the process parameters of the light spots and focus data of the upper and lower lenses, and sends instructions respectively Give the laser cutting head motor control module and the laser cutting head main control board; then, the laser cutting head motor control module moves the position of the nozzle assembly 11 of the laser cutting head to the distance d from the upper surface of the workpiece 201 according to the pro...

Embodiment 3

[0068] Example 3, such as Figure 7 As shown, according to the needs of processing workpiece 301 and workpiece 302, a positive lens is arranged in the upper lens fixing mechanism 3, a positive lens is arranged in the lower lens fixing mechanism 4, and a negative lens is added between the upper lens fixing mechanism 3 and the lower lens fixing mechanism 4. 33. The position of the negative lens 33 is fixed and cannot be moved, and a positive lens is arranged in the focusing optical element fixing mechanism 5 .

[0069] When processing the workpiece 301, first, the sensor control board detects whether the working environment data is qualified; secondly, according to the workpiece 301, the EtherCAT master station retrieves the height data of the laser cutting head and the process parameters of the light spots and focus data of the upper and lower lenses, and sends instructions respectively Give the laser cutting head motor control module and the laser cutting head main control boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com