Cloth cutting device for garments

A cloth and cutting technology, which is applied in the cutting of textile materials, textiles and paper making, etc., can solve the problems of wasting manpower, illegally guaranteeing the service life, and unable to realize the automatic movement of cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

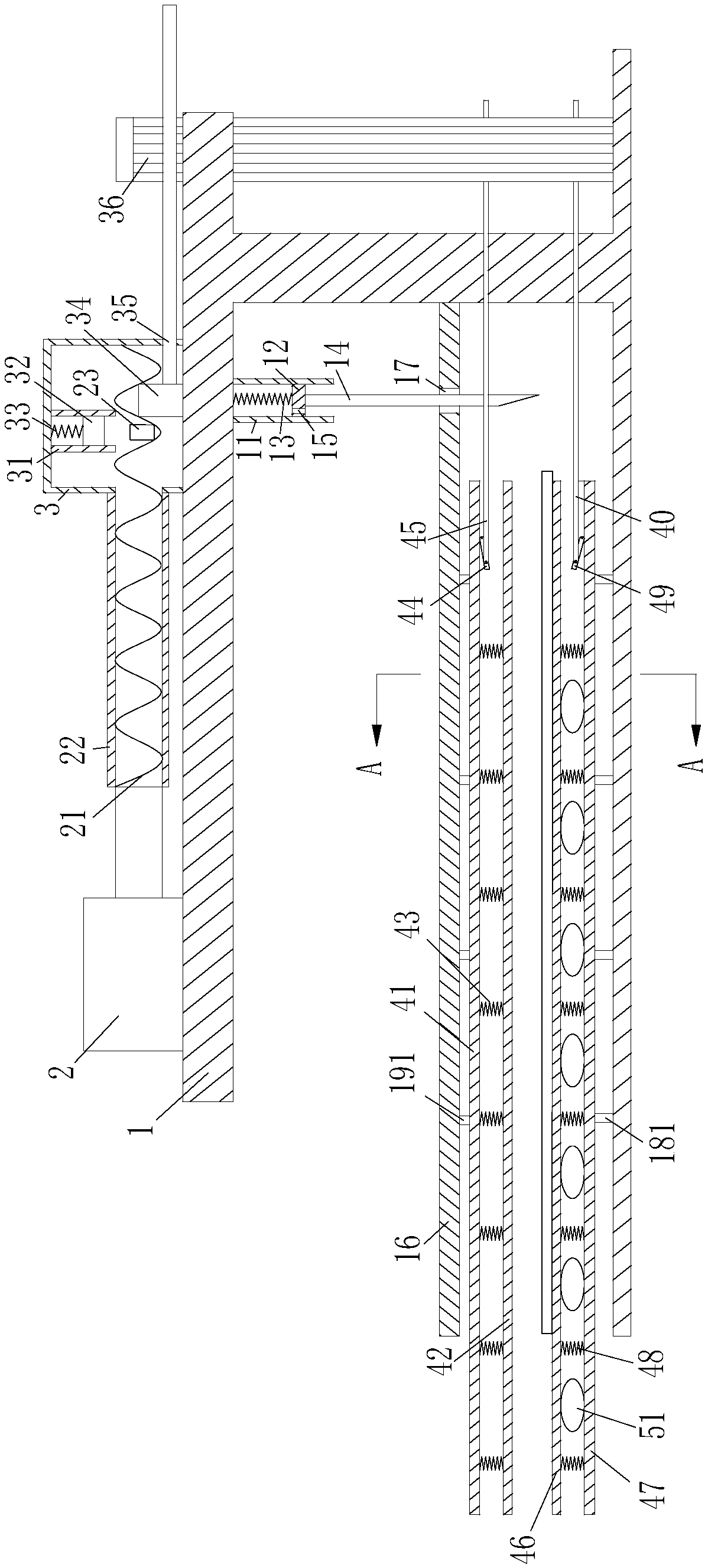

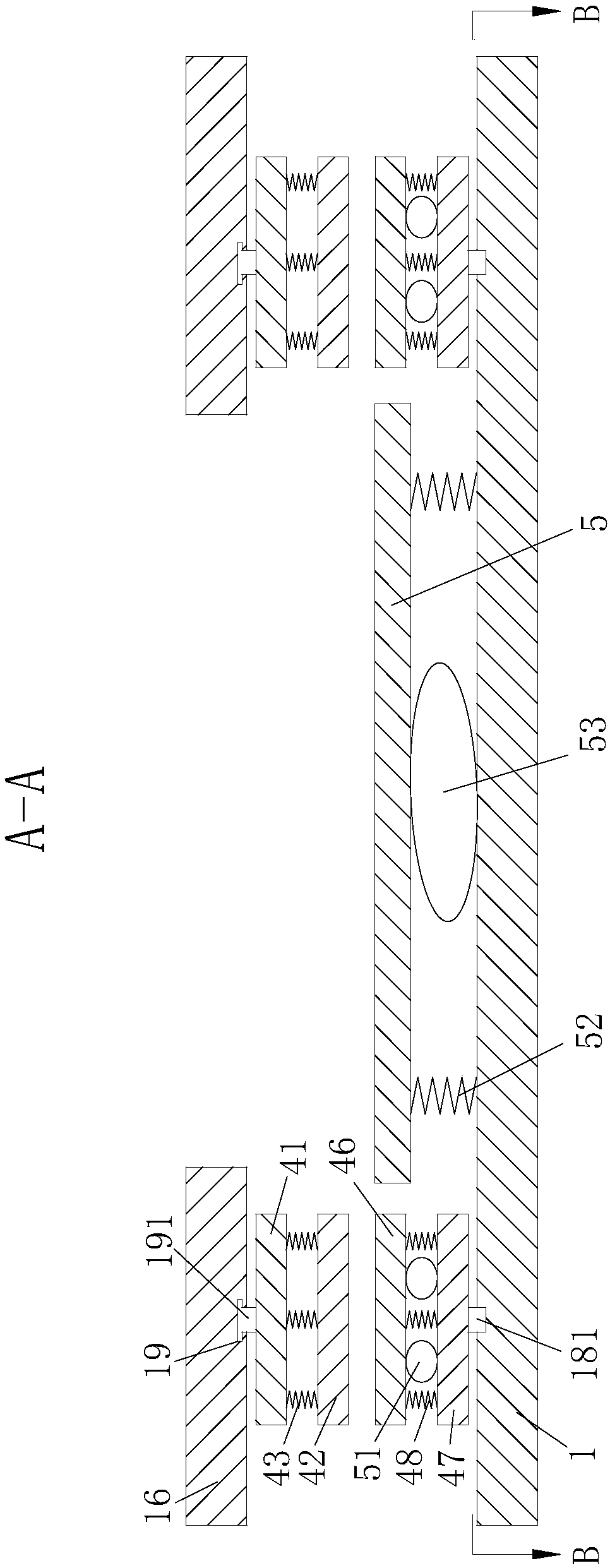

[0025] As an embodiment of the present invention, the transmission cabin 3 is provided with a first slider 34 slidably connected to the upper surface of the frame body 1, and the first slider 34 is located between the two circles of the first spring 21; The motor 2 drives the first spring 21 to rotate forward and backward, and the rotation of the first spring 21 makes the first slider 34 slide left and right; the right side of the first slider 34 is fixedly connected with a first rack 35; The right side of the frame body 1 is provided with a transmission gear 36 vertically arranged and rotatably connected to the upper and lower surfaces of the frame body 1; the first rack 35 is meshed with the transmission gear 36; A rack 35 makes the transmission gear 36 forward and reverse.

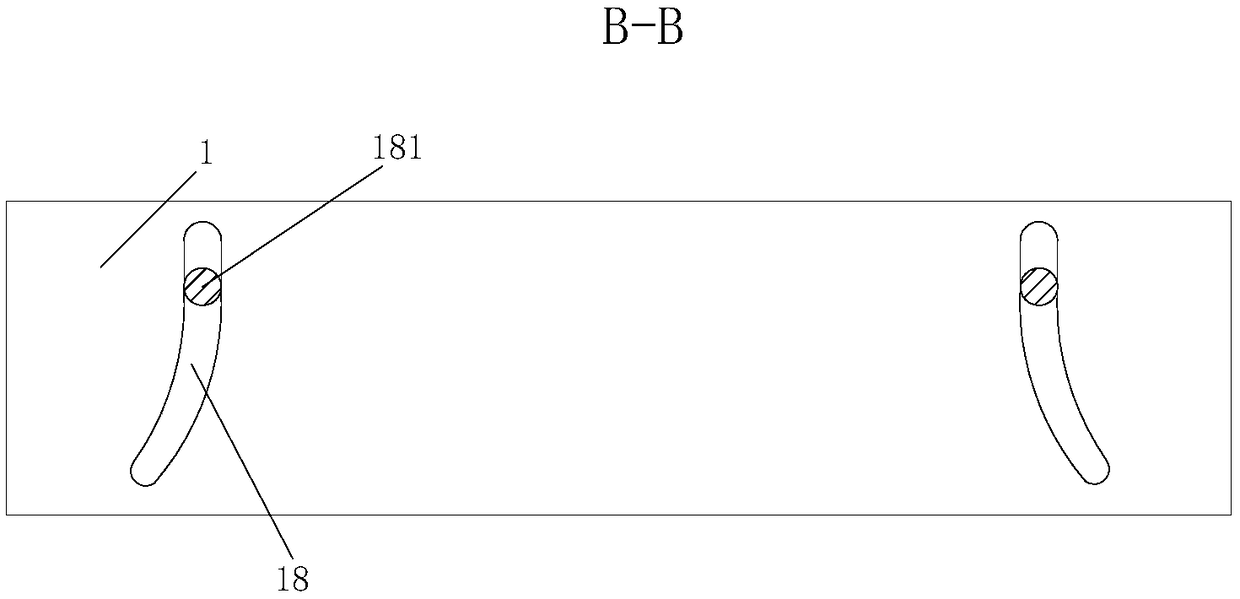

[0026] As an embodiment of the present invention, two clamping units 4 are arranged inside the left frame body 1; above the clamping unit 4, there is a fixed plate arranged horizontally and the right en...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap