An operation control method for tractor dual-flow transmission system

A control method and tractor technology, applied in transmission control, mechanical equipment, components with teeth, etc., can solve problems such as limited mechanical gears, increasing the complexity of the mechanical structure of the gearbox, and the inability to realize continuous stepless transmission. , to achieve the effect of improving productivity and alleviating operational fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

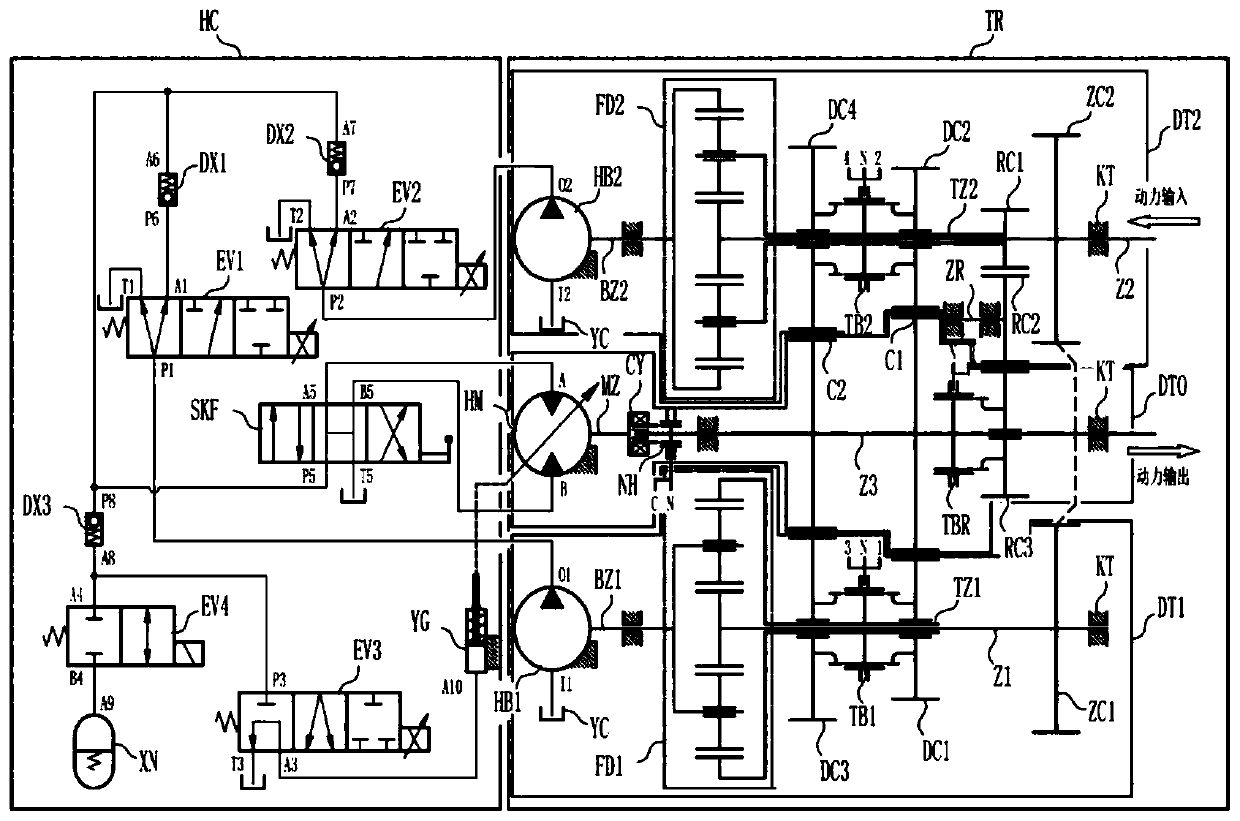

[0038] see figure 1 , the present embodiment is a parallel dual-flow variable speed transmission device, including a variable speed transmission system TR and a hydraulic control system HC, wherein the variable speed transmission system TR is provided with a first power input variable speed transmission unit DT1, a second power input variable speed transmission unit DT2 And the power output unit DT0; the hydraulic control system HC is equipped with the first solenoid valve EV1, the second solenoid valve EV2, the third solenoid valve EV3, the fourth solenoid valve EV4, the manual valve SKF, the first one-way valve DX1, the Second one-way valve DX2, third one-way valve DX3, hydraulic cylinder YG and accumulator XN.

[0039] When this embodiment is in use, it is assumed that the tractor equipped with this type of transmission is in the second gear purely mechanical transmission mode for harvesting operations. When encountering a downhill section, the driving resistance of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com