Automatic steel cylinder filling system and method

A steel cylinder, automatic technology, applied in the direction of container filling method, container discharge method, equipment loaded into pressure vessels, etc., can solve the problems of high manual labor intensity, low production efficiency, frequent handling of steel cylinders, etc., to reduce labor intensity, The effect of simple design and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

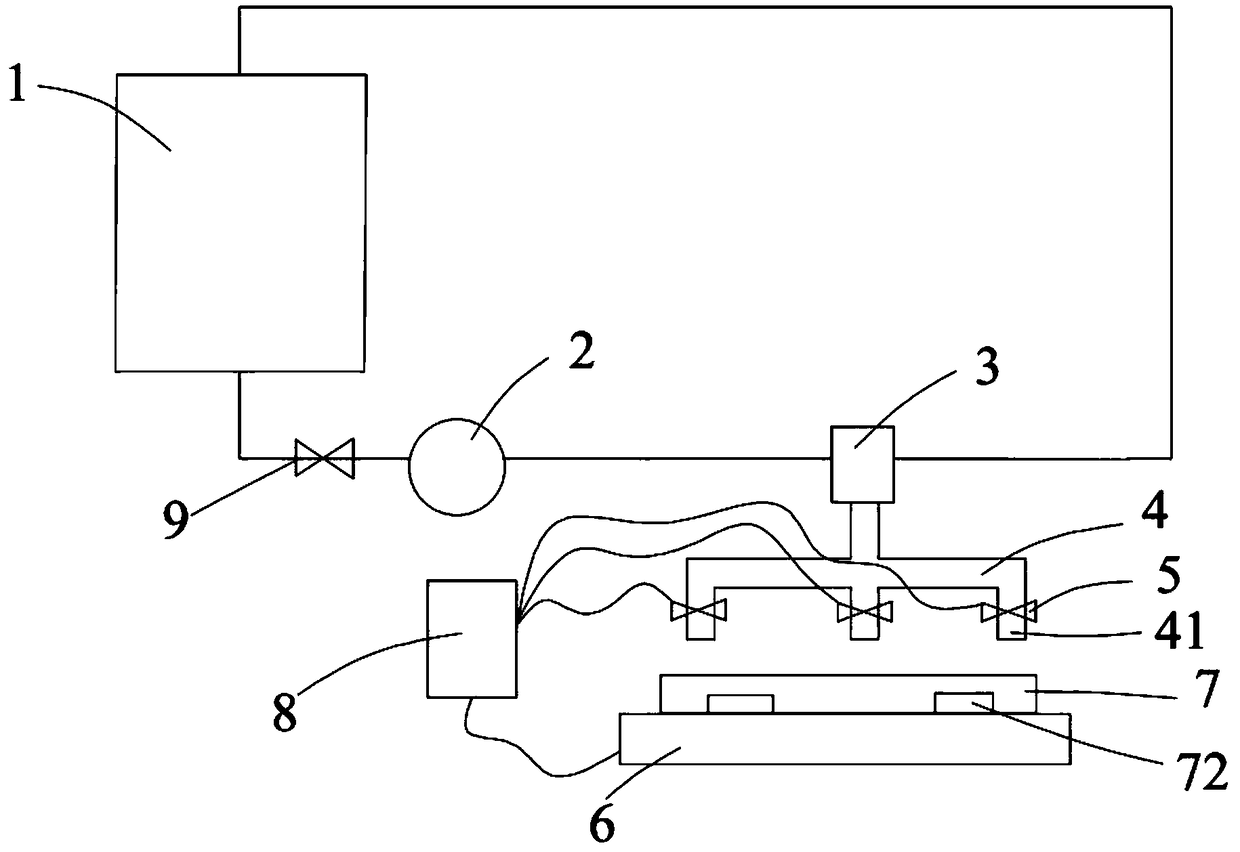

[0023] Please refer to figure 2 and 3 As shown, are respectively the structural schematic diagram of the automatic filling steel cylinder system and the top view of the loading pallet in the present application.

[0024] The application provides an automatic filling cylinder system, which is mainly used in liquid bottling, especially liquid carbon dioxide bottling, which includes a liquid storage tank 1, a filling pump 2, a plurality of inflation valves 3, and a plurality of A plurality of filling pipes 4 corresponding to the inflation valve 3, a plurality of solenoid valves 5, a plurality of weighing devices 6 corresponding to the plurality of charging valves 3, a plurality of loading pallets 7 corresponding to the plurality of weighing devices 6, and PLC control System 8. Among them, the liquid storage tank 1 is mainly used to store liquid carbon dioxide, the filling pump 2 is connected to the liquid storage tank 1 through a pipeline, and the filling pump 2 is mainly used...

Embodiment 2

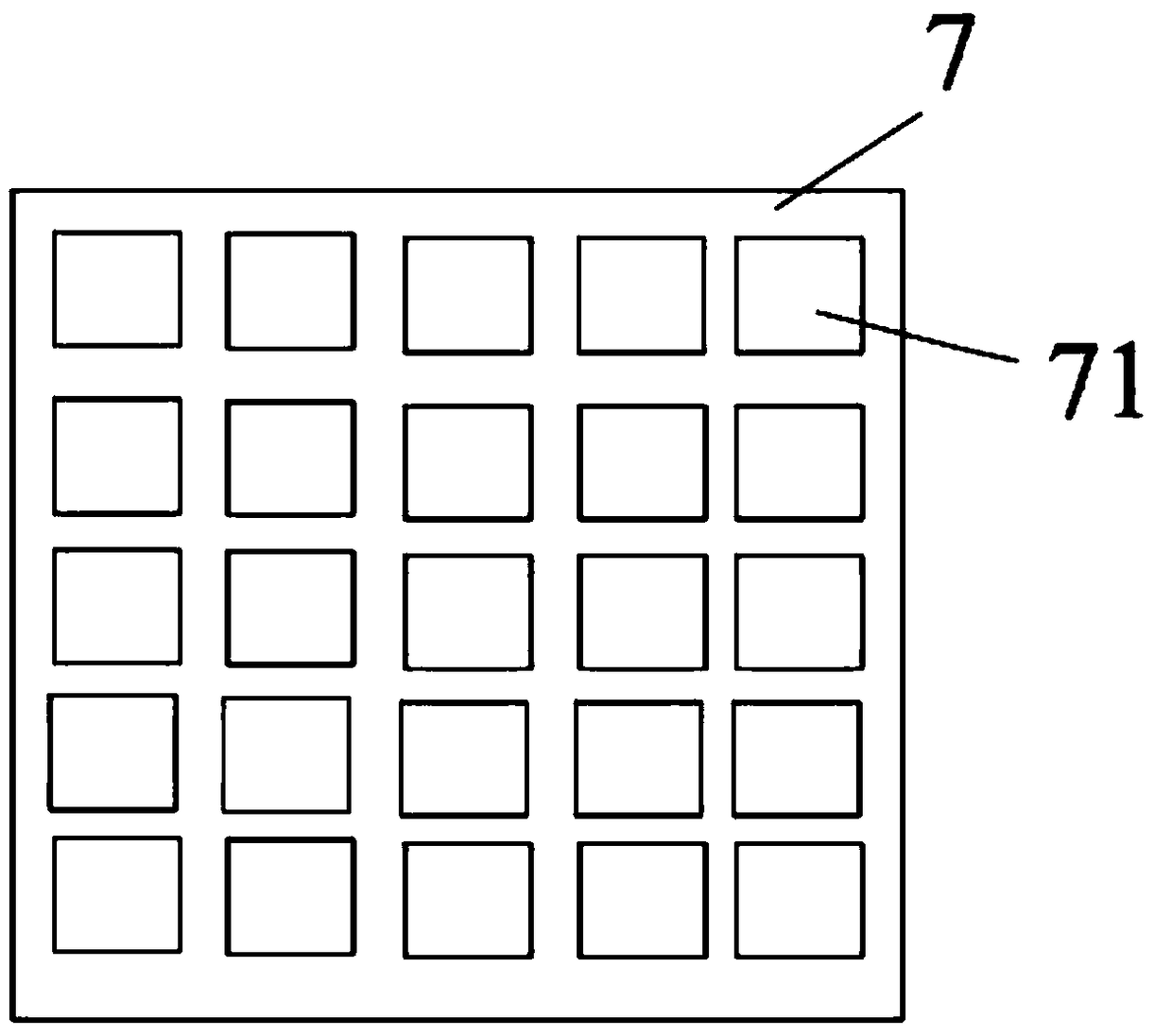

[0030] The present application also provides a method for automatically filling steel cylinders. Below, each filling pipe 4 is provided with 25 filling ports 41, and each loading pallet 7 is provided with 25 loading grooves 71 as an example. The method of automatic filling of steel cylinders will be explained.

[0031] The method for automatically filling steel cylinders comprises the steps:

[0032] S1: Place the steel cylinders to be inflated on the loading slots 71 of the loading pallet 7 , for example, load 25 steel cylinders into the 25 loading slots 71 of the loading pallet 7 .

[0033] S2: Place the loading pallet 7 loaded with steel cylinders on a weight measuring device 6, for example, transport the loading pallet 7 loaded with 25 steel cylinders by means of a forklift and place it on a weight measuring device 6, wherein the forklift It is fixed by the lifting slot 72 at the bottom of the loading pallet 7 .

[0034] S3: Manually install the air inlet of each steel c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap