Multi-layer fly maggot culture device and culture method

A technology of fly maggots and conveyor belts, applied in animal husbandry and other fields, can solve the problems of low mechanization level, low space utilization rate, secondary pollution, etc., and achieve the effect of reducing energy costs, reducing labor costs, and increasing local temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

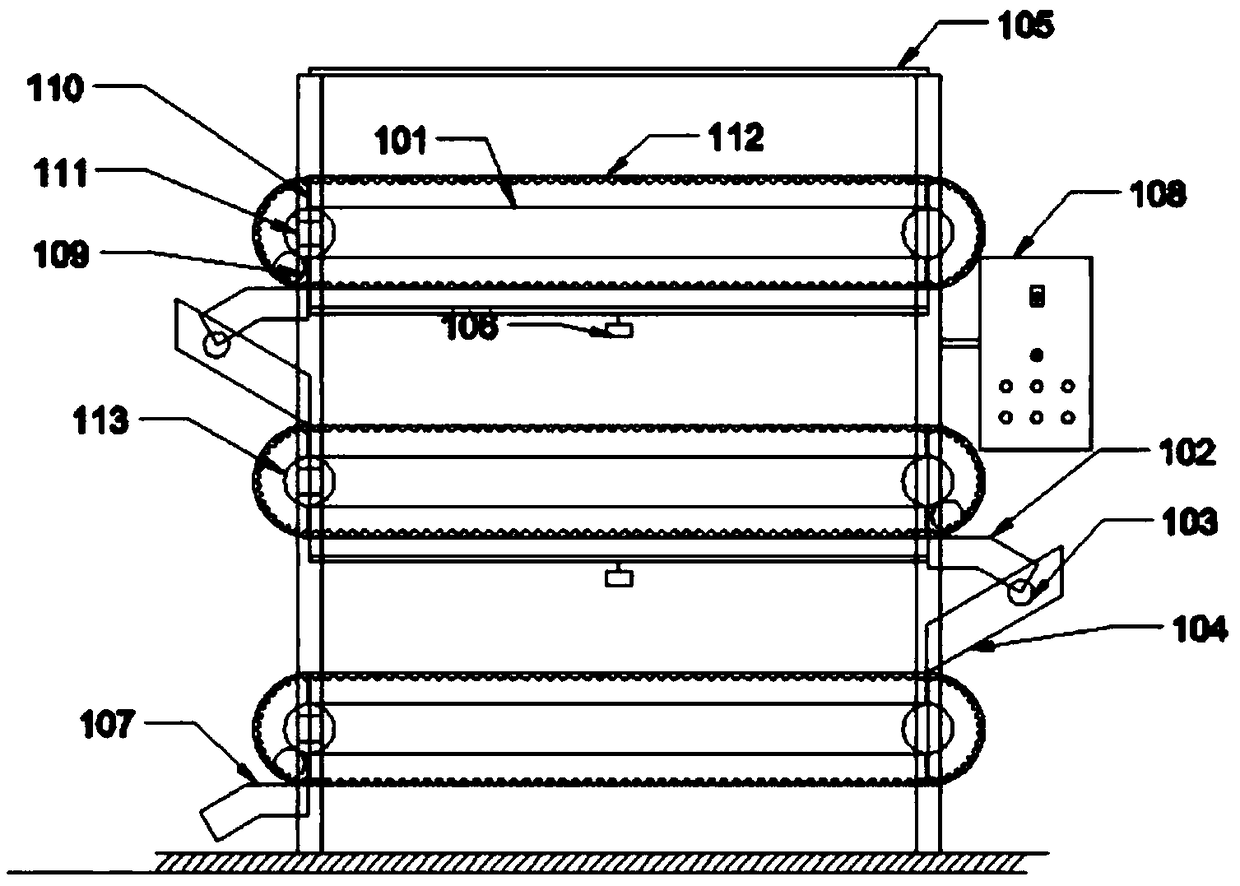

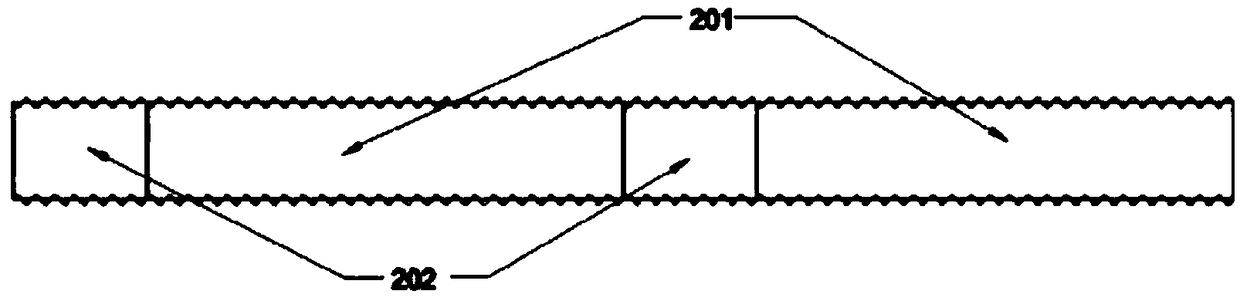

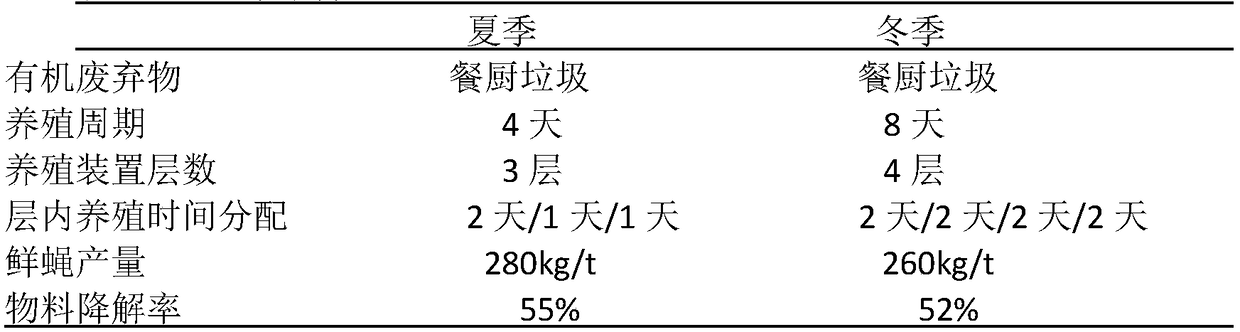

[0024] Such as figure 1 As shown, the multi-layer fly maggot breeding device described in the present embodiment includes three layers of breeding conveyor belts, the conveyor belt width is 1m, and the length is 20m, and the distance between the breeding conveyor belt layer and the layer is 60cm. There are four partitions 110 on the whole conveyer belt, and the conveyer belt is divided into four areas, wherein two large areas are breeding bed areas 201, two small areas are connecting areas 202, and the breeding area is a semi-enclosed space with edges of PVC skirt baffle plate 112, its height is 10cm; The bottom of the left end of the top floor and the bottom culture conveyor belt, the bottom of the right end of the middle layer culture conveyor belt are all fixed with inclined feeding chute, and the lower feeding chute 102 is provided with inclined feeding chute 104 , the inclination angle of the feeding chute and the feeding chute is 120°, a roller 103 is arranged between th...

Embodiment 2

[0034] Such as figure 1 As shown, the present embodiment adopts three layers of fly maggot cultivating device, and the general structure is the same as in embodiment 1, but the conveyor belt width used is 1.5m, and the length is 35m, and the interval between layers of the breeding area is 50cm. The height of the PVC skirt baffle is 10cm; the inclination angles of the feeding chute and the returning chute are both 110°. The organic waste used in this case is fresh pig manure with a water content of 80%, without any other auxiliary materials. The breeding time is autumn, and the breeding cycle is 6 days. The retractable infrared lamp 105 is located above the breeding area; the sprinkler 106 is located below the infrared lamp, but it is not opened in this case.

[0035] Fresh feces and young fly maggots are first dropped on the first layer. Next, after 2 days of fly maggot growth and material transformation, the pile in the first layer has been relatively stable. Turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com