Shock-absorption and breathable insoles and manufacturing method thereof

A production method and a technology for insole, applied in the field of insole, can solve the problems of poor fit of the foot, discomfort, low friction force of the fiber fabric layer, etc., and achieve good adhesion and covering effect, simple production process, composite good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

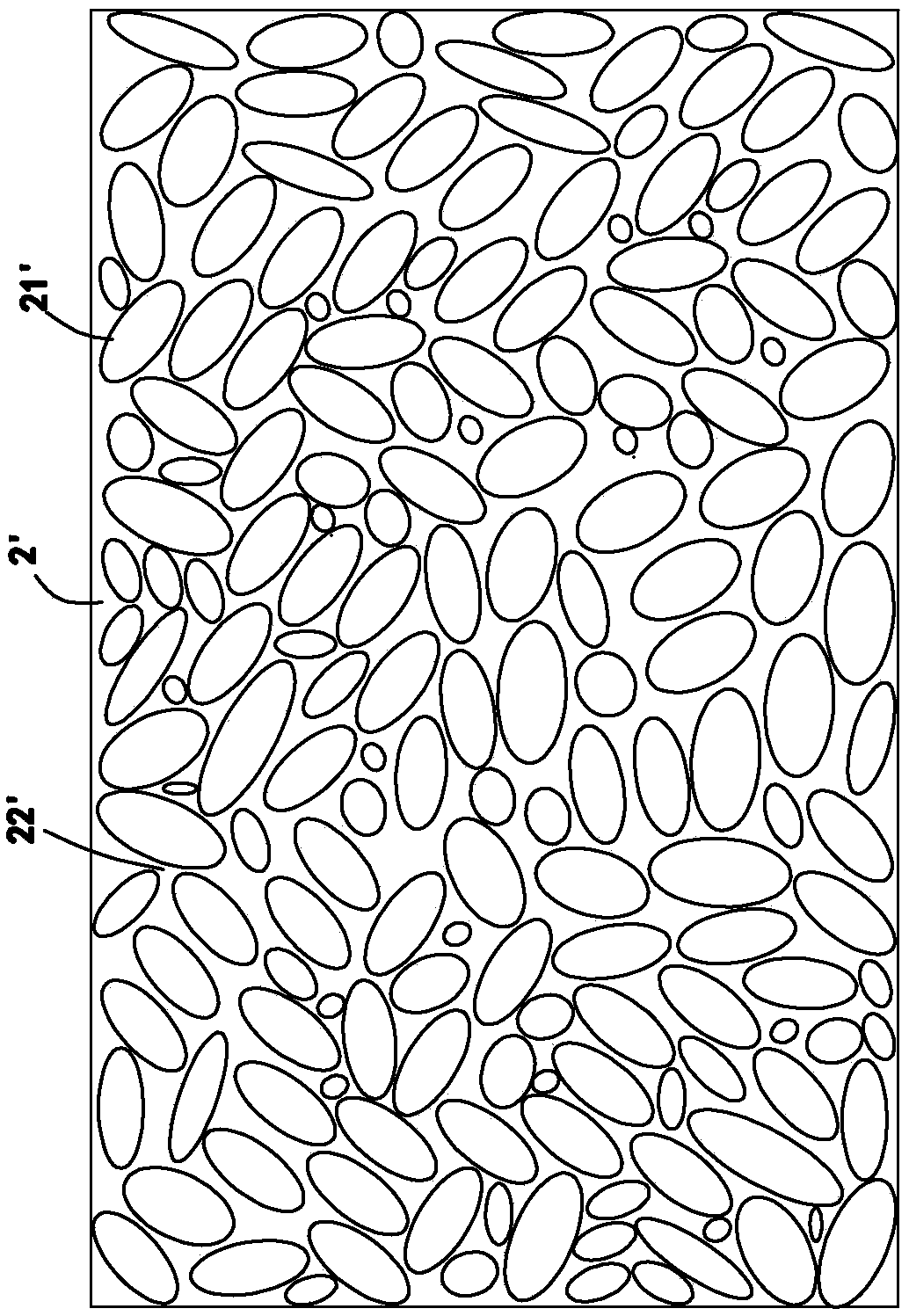

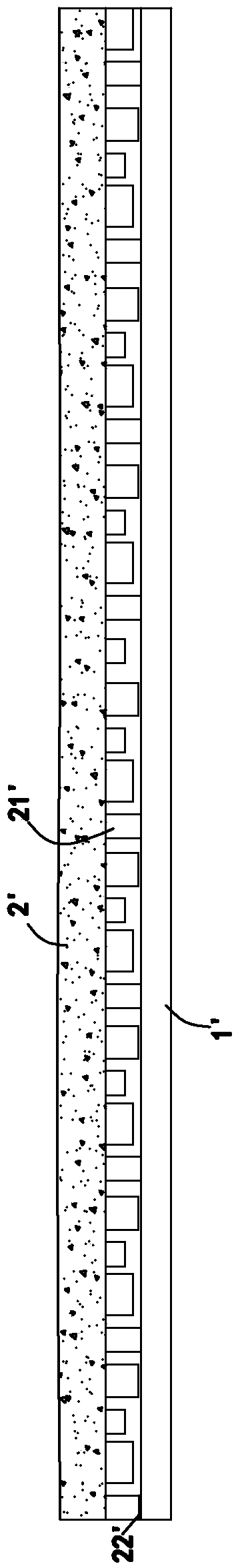

[0026] refer to figure 1 1. A shock-absorbing and breathable insole disclosed in an embodiment of the present invention includes an insole body, the insole body includes a lower bottom 1' and a surface bottom 2', and the lower surface of the surface bottom 2' is evenly distributed with irregular protrusions. 21', the lower surface of the surface bottom 2' is provided with adhesive, and the adhesive penetrates into each irregular protrusion 21', and the surface bottom 2' and the lower bottom 1' are fixed by the adhesive If they are bonded together, the heights of the protrusions 21' are inconsistent, and a ventilation channel 22' leading to the peripheral side of the insole body is formed between the protrusions 21'.

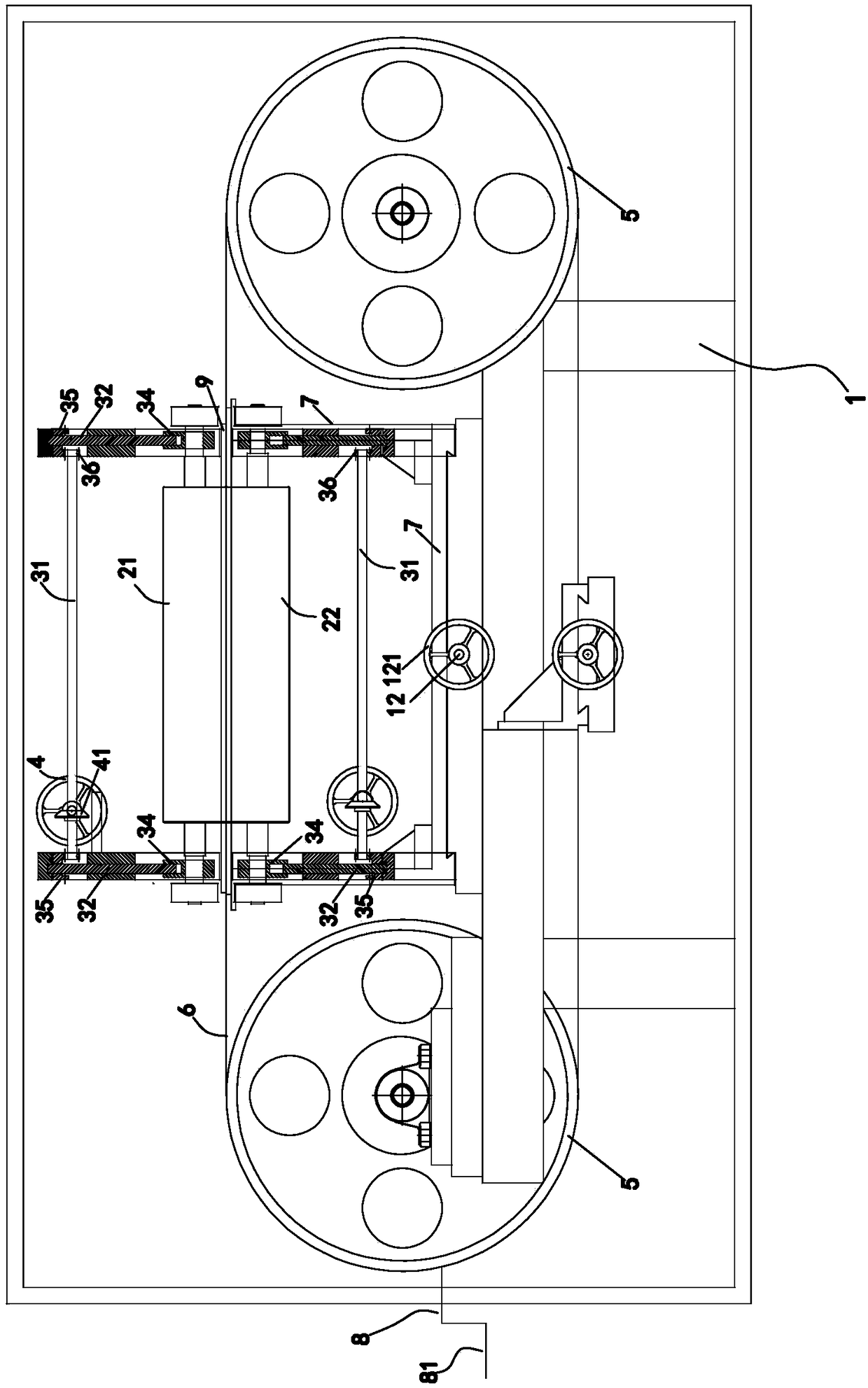

[0027] The manufacture method of above-mentioned shock-absorbing breathable insole comprises the step of making face bottom and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com