Targeted photodynamic nano probe based on upconversion nano particles and ultrathin silicon dioxide layer

A nano-probe and silicon dioxide technology, applied in the field of materials and analytical chemistry, can solve problems such as quenching, achieve the effect of reducing potential and excellent tumor inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

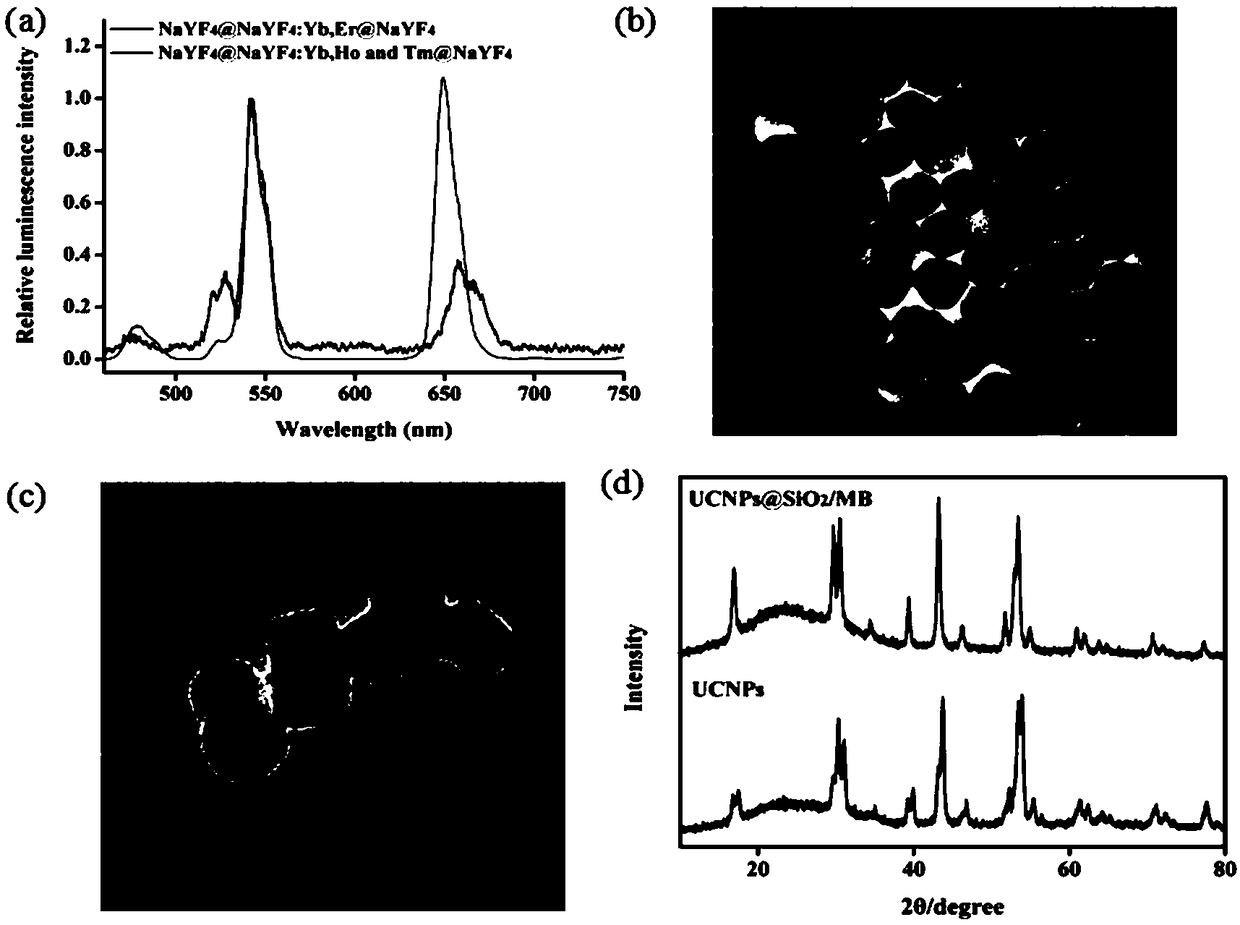

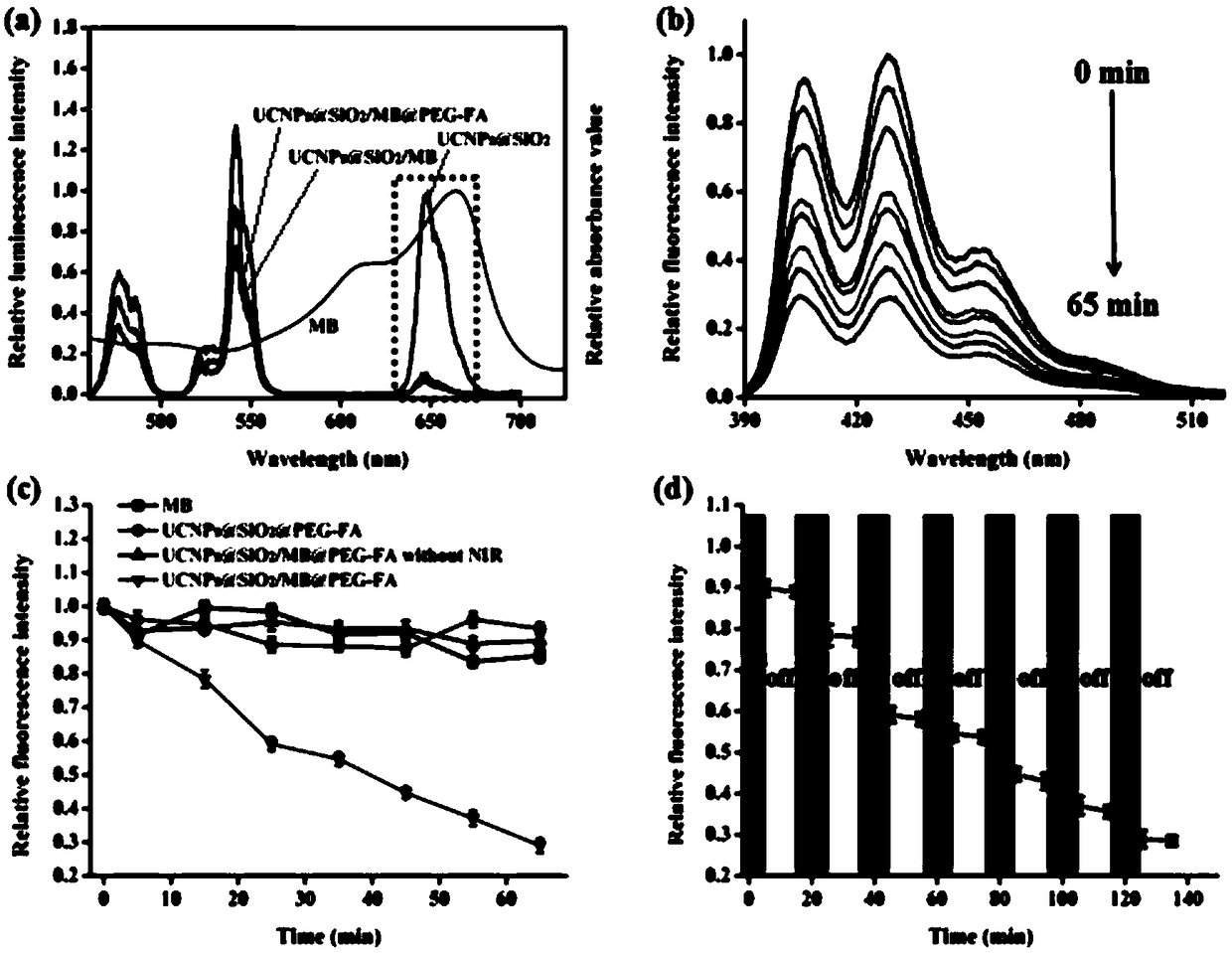

[0036] In a typical embodiment of the present invention, the UCNPs@SiO 2 The preparation method of / MB / PEG-FA nanometer probe, this method comprises:

[0037] (1)UCNPs@SiO 2 Preparation of / MB:

[0038] Mix and stir cyclohexane and surfactant to form reverse micelles, add UCNPs and mix and stir to form a mixed system 1;

[0039] Add methylene blue and ammonia solution to mixing system 1, mix and stir to form mixing system 2;

[0040] Add silicon source to the mixed system 2, mix the reaction, the partially hydrolyzed negatively charged silicon source is transferred to the hydrophilic interior of the reverse micelles to interact with the positively charged methylene blue, and UCNPs@SiO are obtained by hydrolysis and condensation 2 / MB;

[0041] (2)UCNPs@SiO 2 Preparation of / MB / PEG-FA:

[0042] The carboxylated PEG-FA was carboxyl activated, and then the activated mixture was added to the UCNPs@SiO 2 / MB, mixed reaction to prepare UCNPs@SiO 2 / MB@PEG-FA.

[0043] In on...

Embodiment 1

[0053] The NaYF of embodiment 1 oleic acid protection 4 :Yb 3+ ,Ho 3+ / Tm 3+ Preparation of UCNPs:

[0054] (1) Preparation of rare earth oleate

[0055] Weigh 1.129gY 2 o 3 (5mmol) and 20mL concentrated hydrochloric acid in a round-bottomed flask, cover with plastic wrap, pierce holes, and stir at 60°C. After reacting overnight, adjust the temperature to 140°C, evaporate concentrated hydrochloric acid to obtain YCl 3 . Synthesized YCl 3 Add 10mL of ultrapure water and ultrasonically dissolve. Then add 5mL of ultrapure water, filter it with a syringe and a 0.22um green filter, inject it into a flask, add 20mL of ethanol, 35mL of cycloethane, and 30mmol of sodium oleate, and reflux at 78°C for 4h. Then lower the temperature to 30-40°C, transfer it into a separatory funnel, and take the upper layer solution. Then add 20mL ultrapure water and 20mL ethanol (shake evenly). Take the upper layer by layer, and separate the liquid three times. Then move it into a round bot...

Embodiment 2

[0060] The NaYF of embodiment 2 oleic acid protection 4 :Yb 3+ ,Er 3+ Preparation of UCNPs:

[0061] Same as Example 1, the difference is: in the oleate of the light-emitting layer, Y:Yb:Er=80:18:2, the molar ratio, the total molar number is 5 mmol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com