Disc type filtering machine for low product water content of fine-particle ores

A disc filter and fine particle technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of large filter cake layer thickness, large suction pressure, large energy consumption, etc., and achieve filtration products. The effect of low moisture, avoidance of gas waste, and high vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

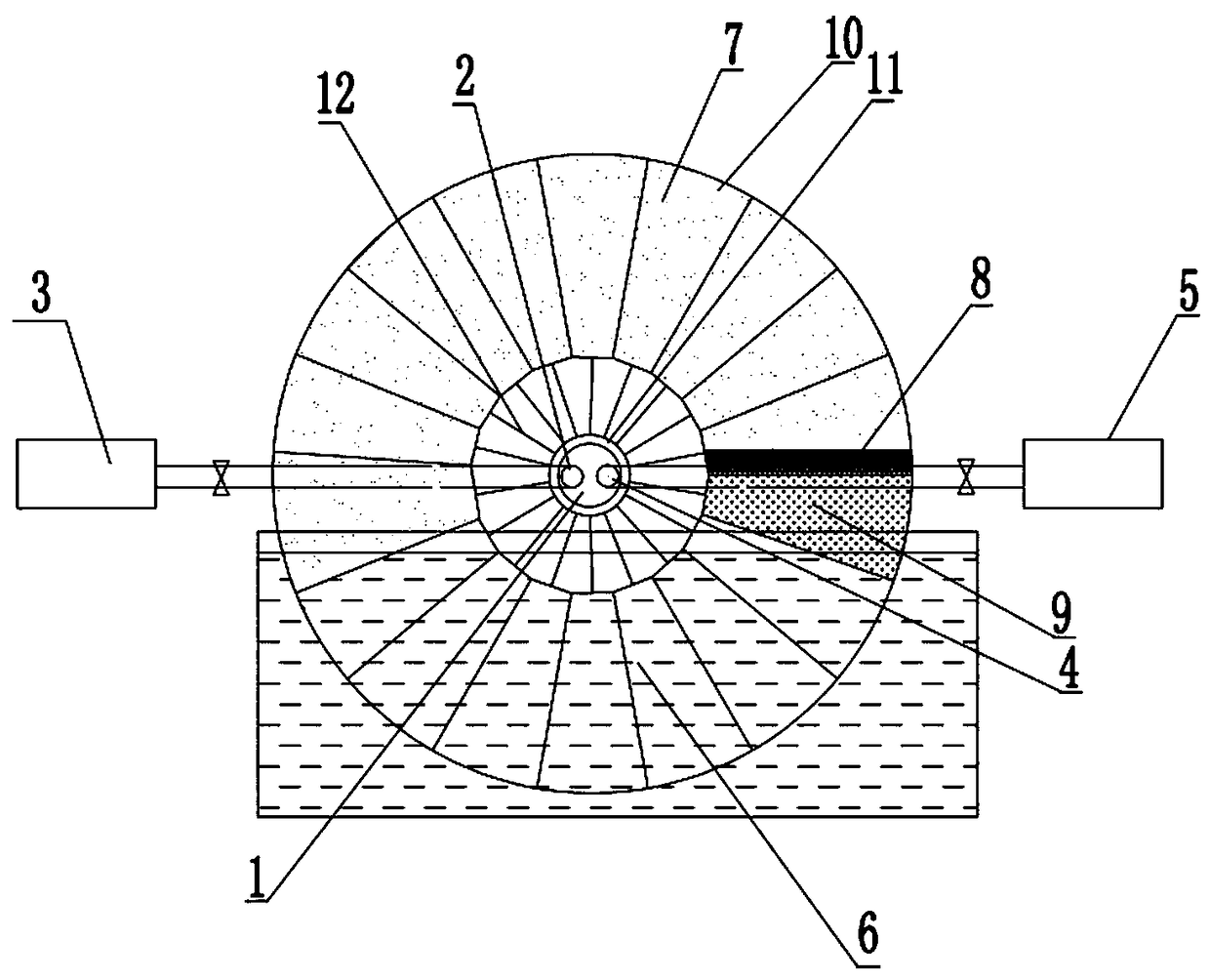

[0019] Such as figure 1 As shown, the micro-fine ore low-product moisture disc filter of the present invention is characterized in that it includes a main shaft 11, through several filter discs arranged along the circumference of the main shaft 11, the distribution head 1 arranged on the main shaft 11, each The filter disc is composed of several filter fans 10 inserted on the main shaft 11, and each filter fan 10 is plugged on the main shaft 11 through a filter rod 12, and each filter disc includes a liquid suction area 6, a suction dry Zone 7, discharge zone 8 and transition zone 9, the liquid suction zone 6 on each filter disc is connected to the liquid suction port 2 on the distribution head 1, and the liquid suction port 2 is connected to the liquid suction port through a pipeline The vacuum pumps 3 are connected, and the dry-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com