Industrial dust remover

A dust collector and dust technology, which is applied to chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of large noise pollution, poor dust removal effect, etc., and achieve the goals of reducing waste, stabilizing confluence, and improving processing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

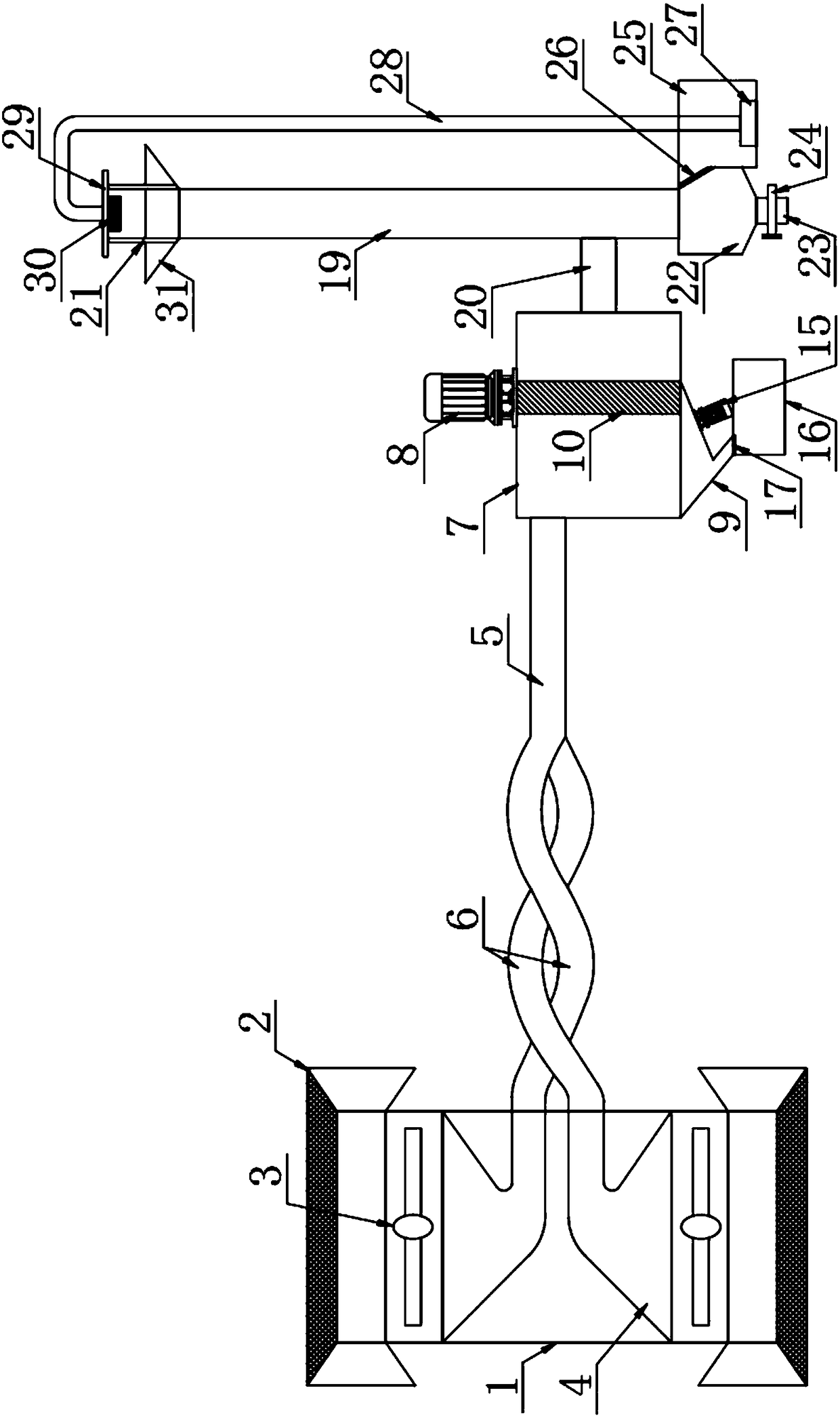

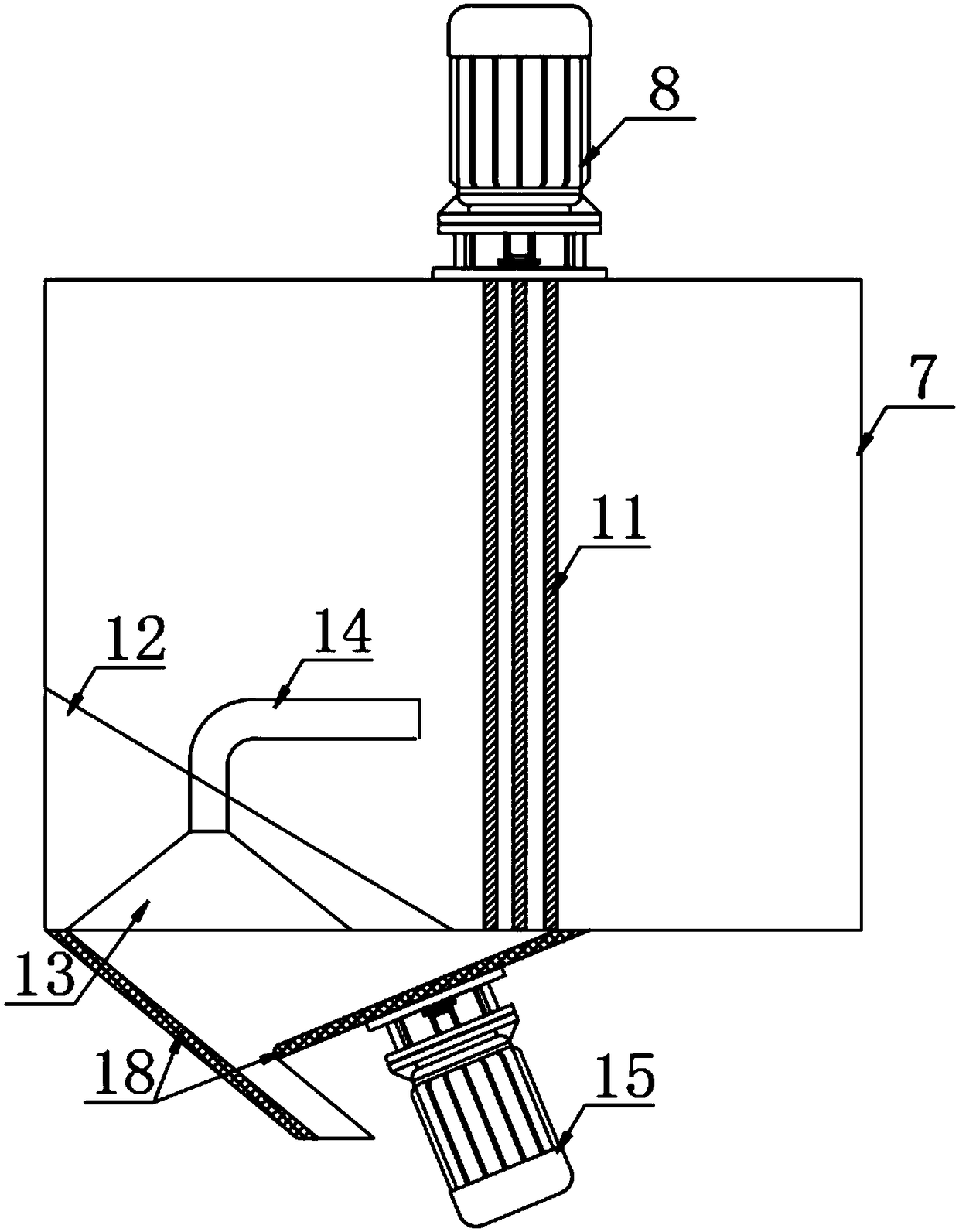

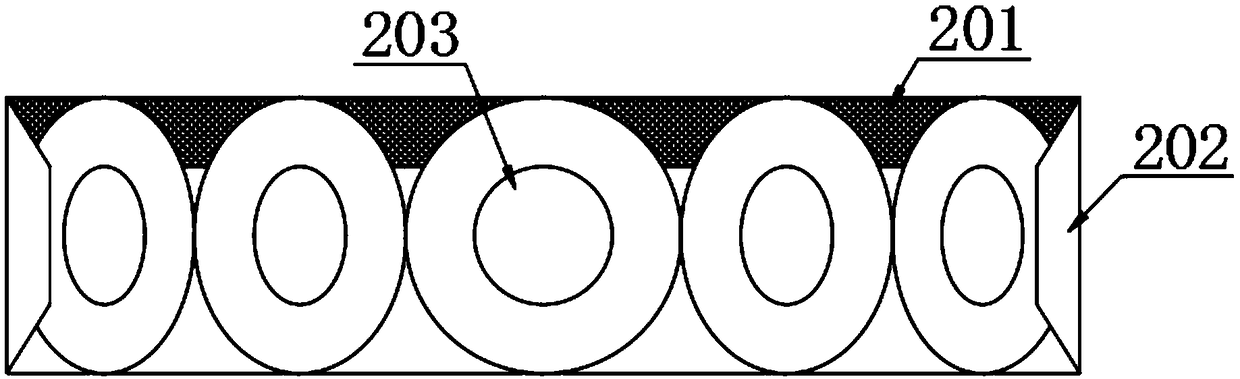

[0027] The present invention provides such Figure 1-5 The shown industrial dust collector includes a connecting sleeve 1, and both ends of the connecting sleeve 1 are provided with an air inlet mechanism 2, and the air inlet mechanism 2 includes a first flared groove 201 and a second flared groove. The first flared groove 201 and the second flared groove 202 are vertically arranged, and the shrinking ends of the first flared groove 201 and the second flared groove 202 are equipped with an air inlet 203, The connection between the connecting sleeve 1 and the air inlet mechanism 2 is provided with a turbofan 3, and the bottom of the turbofan 3 is provided with an air-introduction chamber 4, and the air-introduction chamber 4 is arranged inside the connecting sleeve 1, and the connecting sleeve One side of cylinder 1 is provided with a main pipe 5, and a spiral connecting pipe 6 is arranged between the said air-inducing chamber 4 and the main pipe 5, and the two are connected th...

Embodiment 2

[0030]Further, in the technical solution of Example 1, the inner wall of the dust discharge port 9 is provided with a drain plate 18, and the number of the drain plate 18 is two, and they are respectively arranged on the left and right sides of the dust discharge port 9. On the inclined side wall, the length of the flow guide plate 18 of the left side wall is greater than the length of the flow guide plate 18 of the right side wall, so that the part wind in the dust removal box forms a return air passage under the cooperation of the left and right two flow guide plates 18, so that The guided return wind flows into the return air slot 13, and is returned to the dust removal box by the return air pipe 14 at the end of the return air slot 13, so as to avoid the problem of dust flying caused by the wind flowing into the dust collection box 16.

[0031] Further, in the technical solution of Example 1, the inner wall of the main pipe 5 is provided with a spiral air guide plate 32, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com