Comprehensive dust removing system for stone production

A dust removal system and stone technology, applied in the direction of dust removal, cleaning methods and tools, grain processing, etc., can solve the problems of increasing operating costs, secondary dust, ineffective use of ash powder, and low equipment utilization, and achieve ash conveying equipment Small size, improved operating efficiency, and low operating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

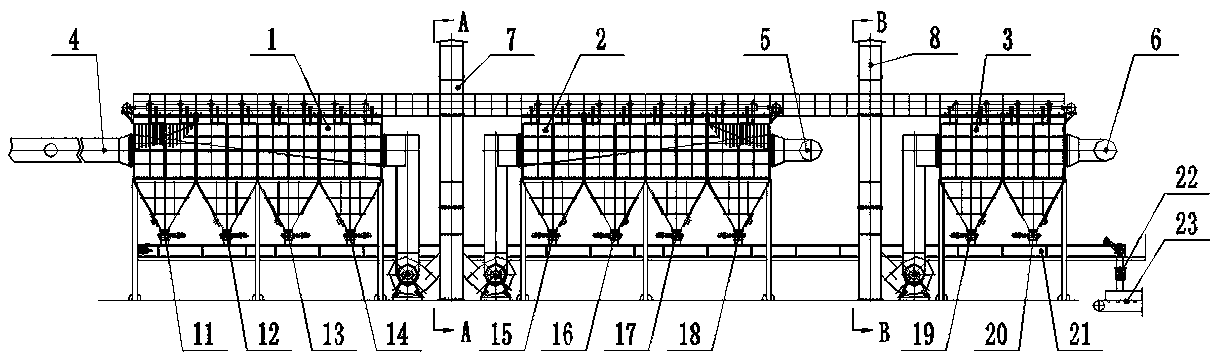

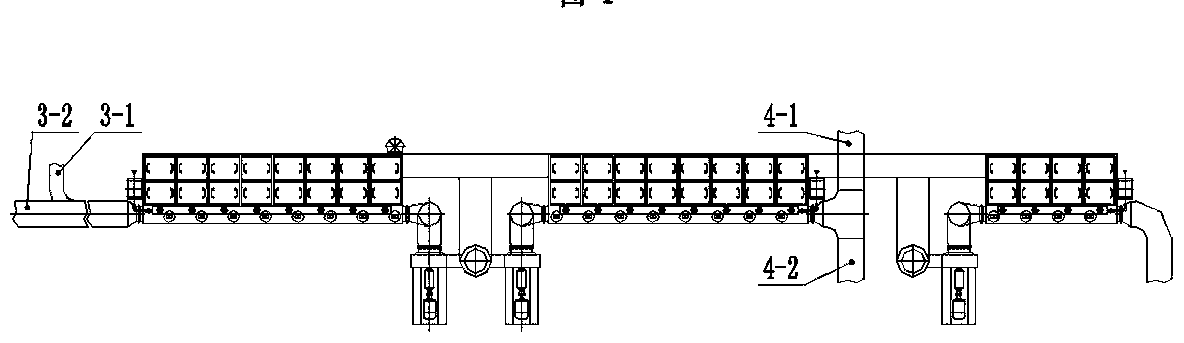

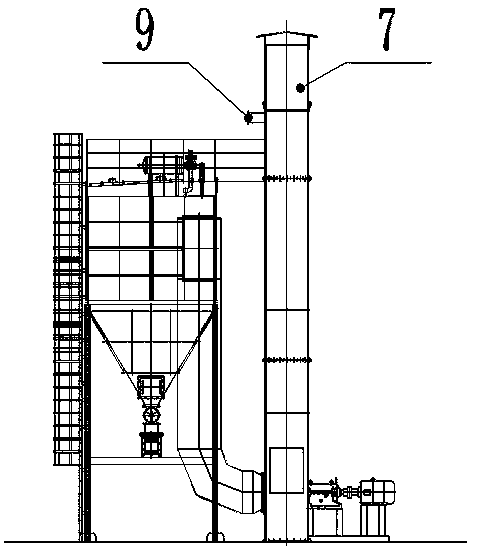

[0017] Embodiment: A comprehensive dust removal system for stone production, including a crushing dust collector 1 for feeding, a dust collector 2 for vibrating screen, a dust collector 3 for machine-made sand, a dust collection pipe for feeding crushing 4, a dust collection pipe for vibrating screen 5, and dust collection for machine-made sand Pipeline 6, first exhaust chimney 7, second exhaust chimney 8, first dust concentration sensor 9, second dust concentration sensor 10, first unloader 11, second unloader 12, third unloader 13. The fourth unloader 14, the fifth unloader 15, the sixth unloader 16, the seventh unloader 17, the eighth unloader 18, the ninth unloader 19, the tenth unloader 20 , Dust collector scraper machine 21, dust collector reload scraper machine 22 and 0-3mm finished product belt conveyor 23, in which: material crushing dust collector 1, vibrating screen dust collector 2 and machine-made sand dust collector 3 are arranged in a row, The ash collecting hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com