Welding mechanical arm capable of preventing sparks from splashing and working method of welding mechanical arm

A technology for welding machinery and robotic arms, applied in the field of intelligent robotic arms, can solve problems such as reducing the space of drive joints, and achieve the effects of eliminating inertia and sliding, ensuring production accuracy, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

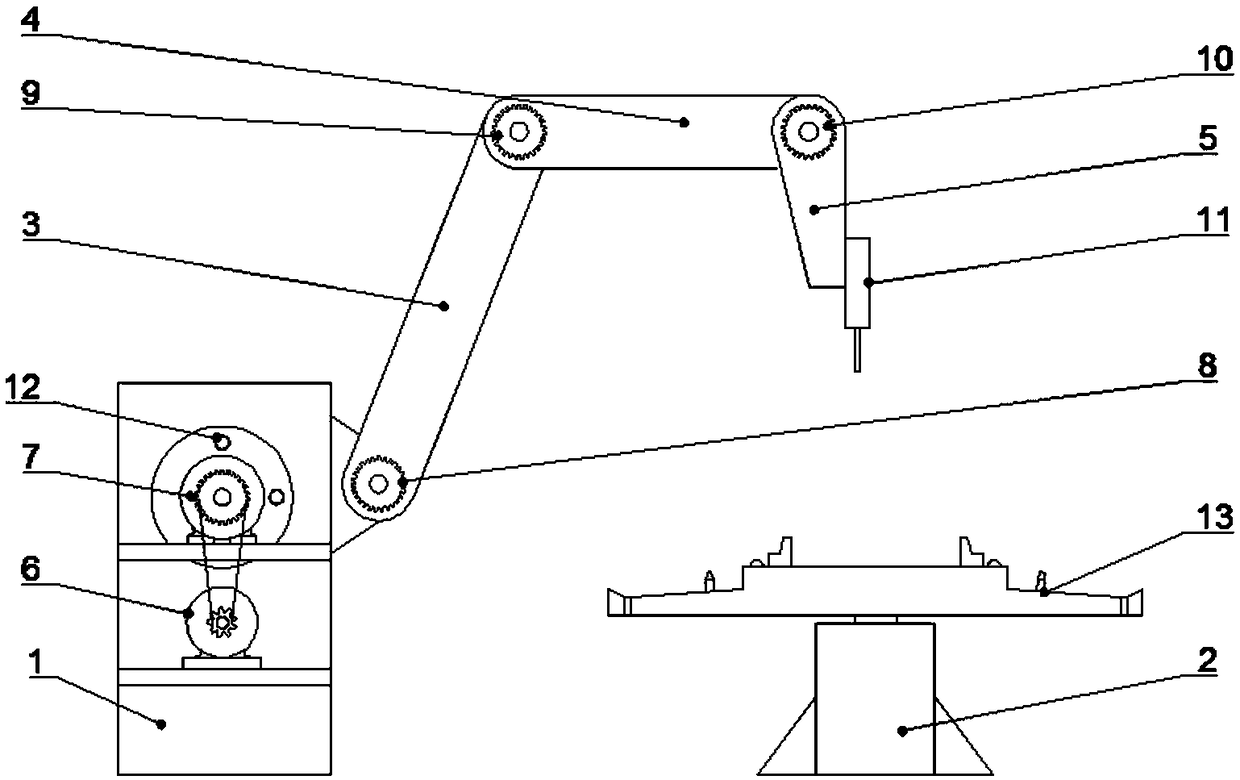

[0046] Such as figure 1 A spark spatter-proof welding robot arm is shown, including: a base 1, a rotating workpiece table 2, a first robot arm 3, a second robot arm 4, a third robot arm 5, a driving motor 6, and a transmission gearbox 7 , the first rotating sprocket group 8, the second rotating sprocket group 9, the third rotating sprocket group 10 and the end welding torch 11, the base 1 side is provided with a rotary table 2, and the base 1 upper end is provided with There is a first mechanical arm 3, the base 1 is hinged to the first mechanical arm 3, and one end of the first mechanical arm 3 is provided with a second mechanical arm 4, and the first mechanical arm 3 is hinged to the second mechanical arm 4 , one end of the second mechanical arm 4 is provided with a third mechanical arm 5, the second mechanical arm 4 is hinged with the third mechanical arm 5, and one end of the third mechanical arm 5 is fixed with a terminal welding torch 11; the base 1 is provided with a d...

Embodiment 2

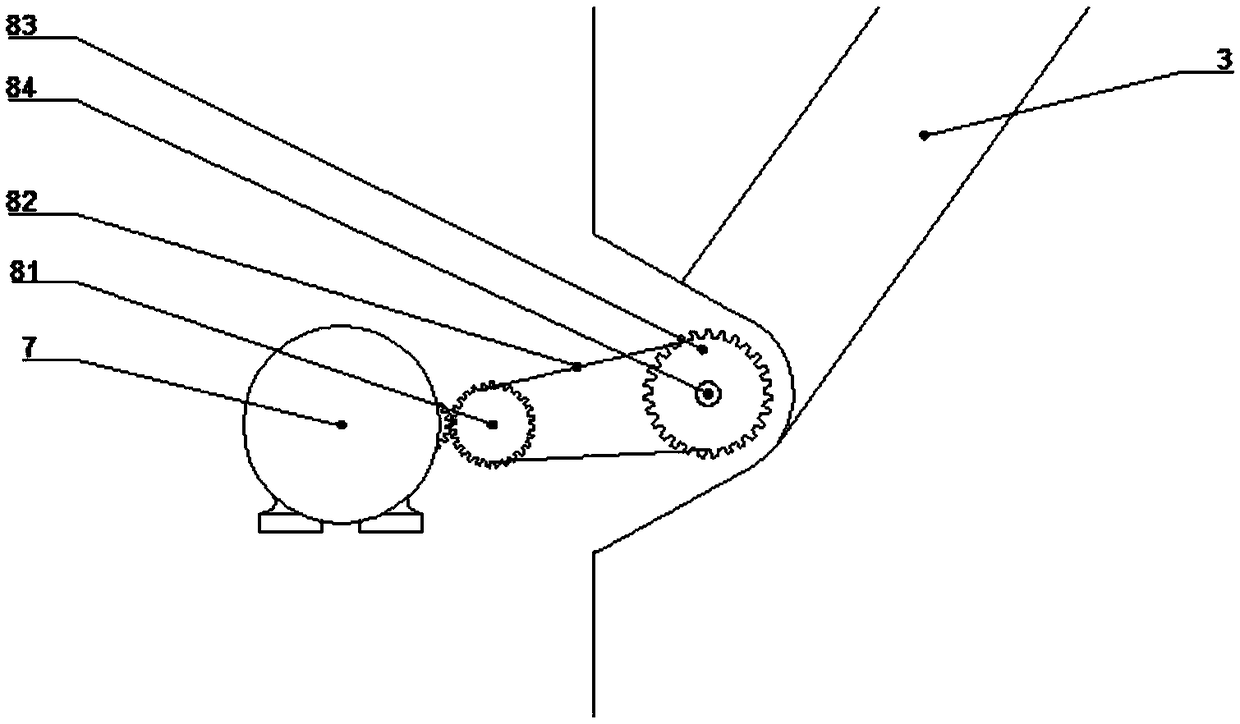

[0064] Such as figure 2 A spark spatter-proof welding robot arm is shown, including: a base 1, a rotating workpiece table 2, a first robot arm 3, a second robot arm 4, a third robot arm 5, a driving motor 6, and a transmission gearbox 7 , the first rotating sprocket group 8, the second rotating sprocket group 9, the third rotating sprocket group 10 and the end welding torch 11, the base 1 side is provided with a rotary table 2, and the base 1 upper end is provided with There is a first mechanical arm 3, the base 1 is hinged to the first mechanical arm 3, and one end of the first mechanical arm 3 is provided with a second mechanical arm 4, and the first mechanical arm 3 is hinged to the second mechanical arm 4 , one end of the second mechanical arm 4 is provided with a third mechanical arm 5, the second mechanical arm 4 is hinged with the third mechanical arm 5, and one end of the third mechanical arm 5 is fixed with a terminal welding torch 11; the base 1 is provided with a ...

Embodiment 3

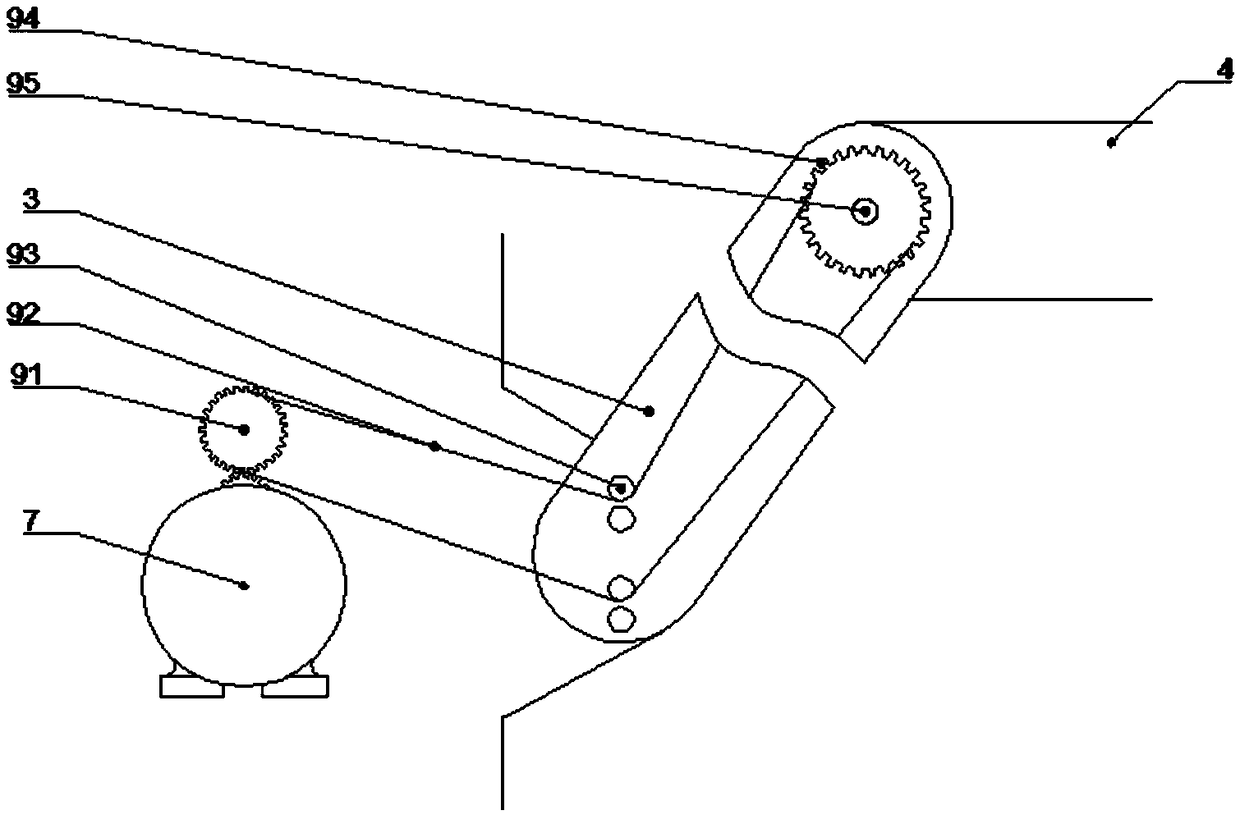

[0067] Such as image 3 A spark spatter-proof welding robot arm is shown, including: a base 1, a rotating workpiece table 2, a first robot arm 3, a second robot arm 4, a third robot arm 5, a driving motor 6, and a transmission gearbox 7 , the first rotating sprocket group 8, the second rotating sprocket group 9, the third rotating sprocket group 10 and the end welding torch 11, the base 1 side is provided with a rotary table 2, and the base 1 upper end is provided with There is a first mechanical arm 3, the base 1 is hinged to the first mechanical arm 3, and one end of the first mechanical arm 3 is provided with a second mechanical arm 4, and the first mechanical arm 3 is hinged to the second mechanical arm 4 , one end of the second mechanical arm 4 is provided with a third mechanical arm 5, the second mechanical arm 4 is hinged with the third mechanical arm 5, and one end of the third mechanical arm 5 is fixed with a terminal welding torch 11; the base 1 is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com