A technology for dismantling the bearing spring of bogie

A technology for dismantling technology and bogies, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of potential safety hazards, high labor intensity, and low work efficiency, so as to improve disassembly efficiency, reduce labor intensity, and improve The effect of pick-and-place efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

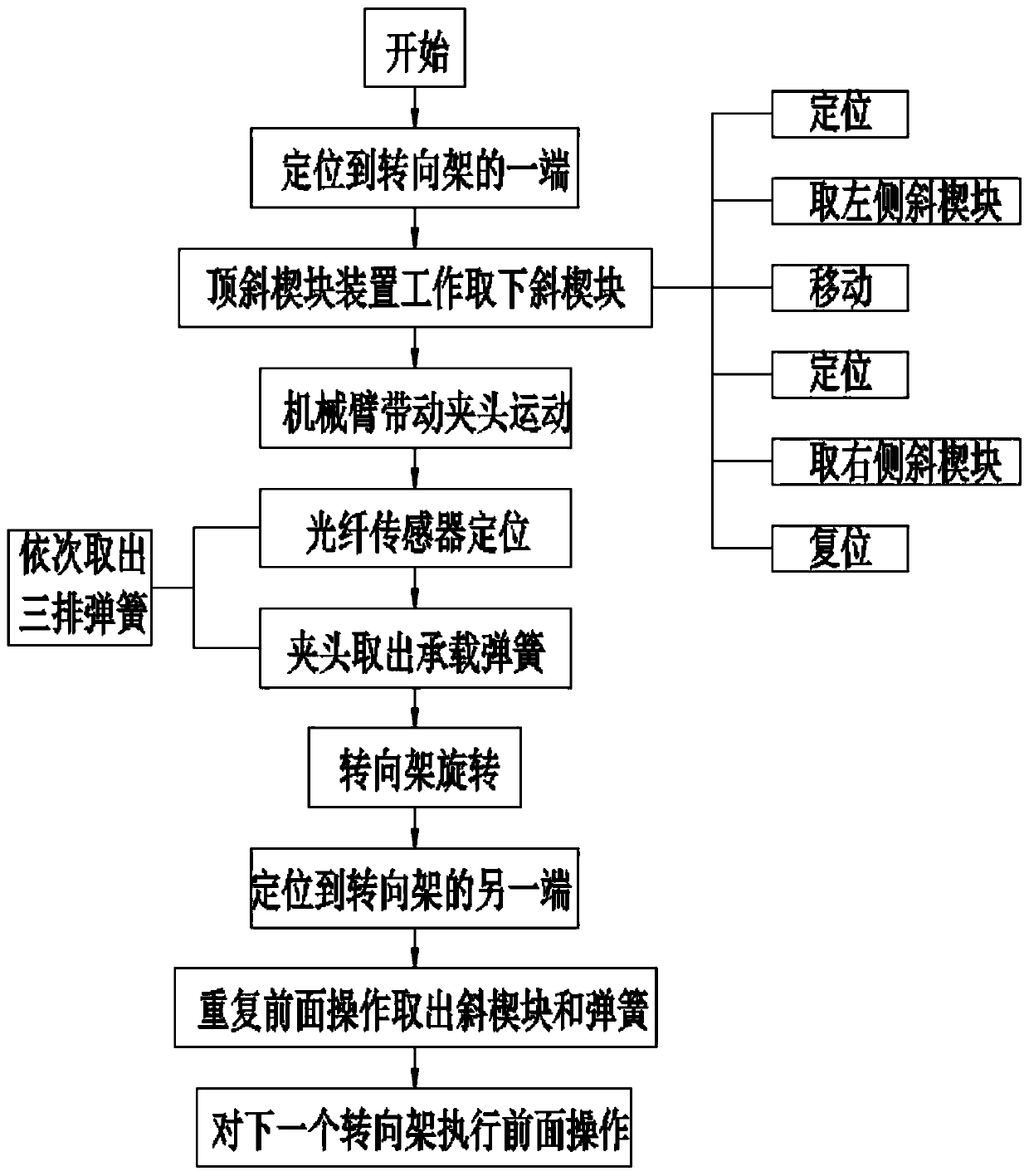

[0051] The bogie bearing spring dismounting process of the present invention comprises the following steps:

[0052] S1 is positioned to one end of the bogie 5;

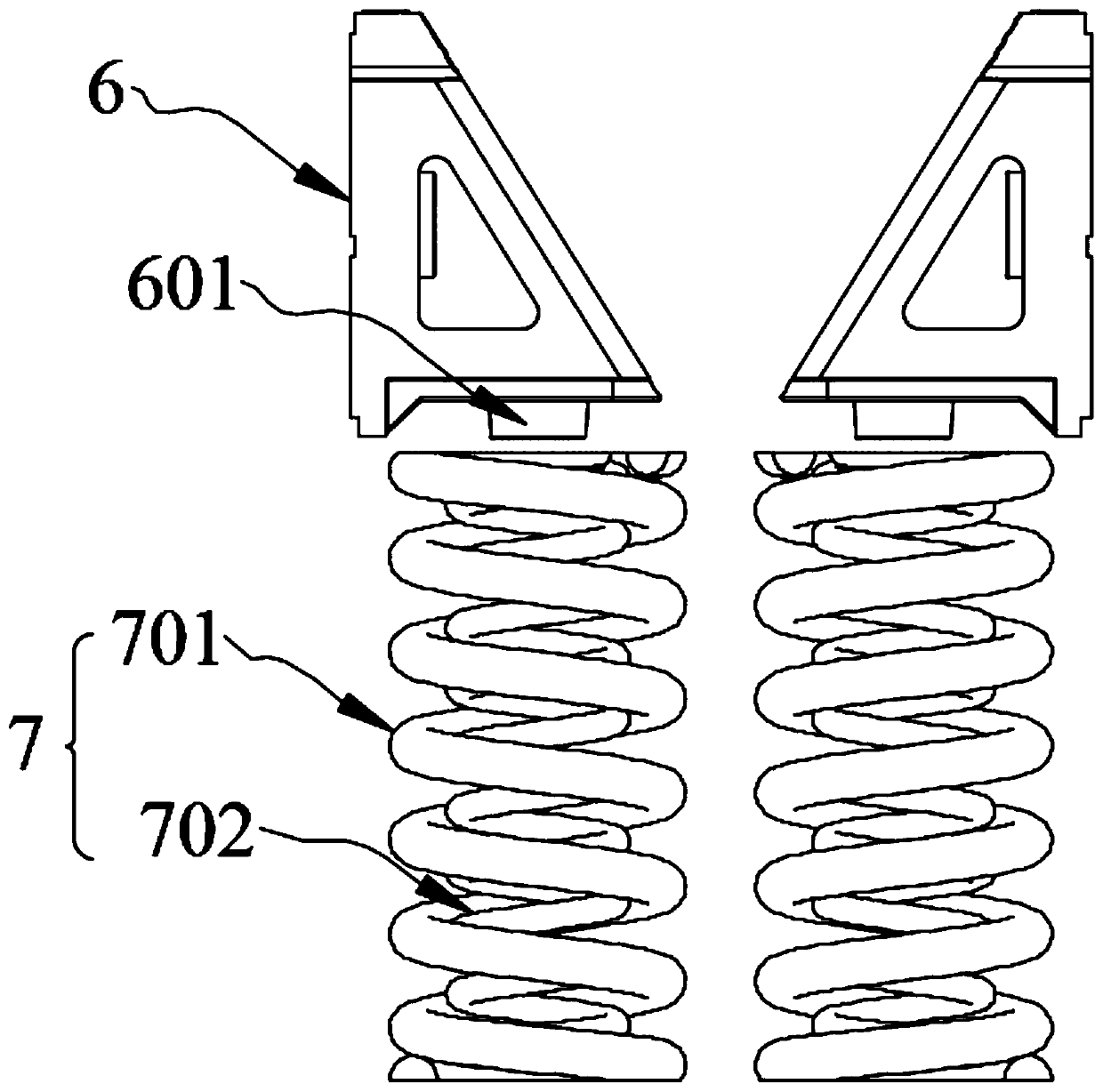

[0053] The S2 jacking device works to remove the wedge block 6;

[0054] The jacking device includes a jacking unit 4 and a three-axis cantilever. There are two jacking units 4, and the movement of the jacking unit 4 in space is realized through the three-axis cantilever, and the wedge on the left side of one of the jacking units 4 is completed. Positioning of block 6, then remove the left side wedge block 6, then move another jacking unit, 4 position the right side wedge block, 6, then remove the right side wedge block 6, and finally reset ;

[0055] S3 mechanical arm 2 drives chuck 1 to move;

[0056] The chuck 1 and the mechanical arm 2 are connected to each other through a flange 10;

[0057] S4 positioning device locates the bearing spring 7;

[0058] The through-beam optical fiber sensor 1021 positions the...

Embodiment 2

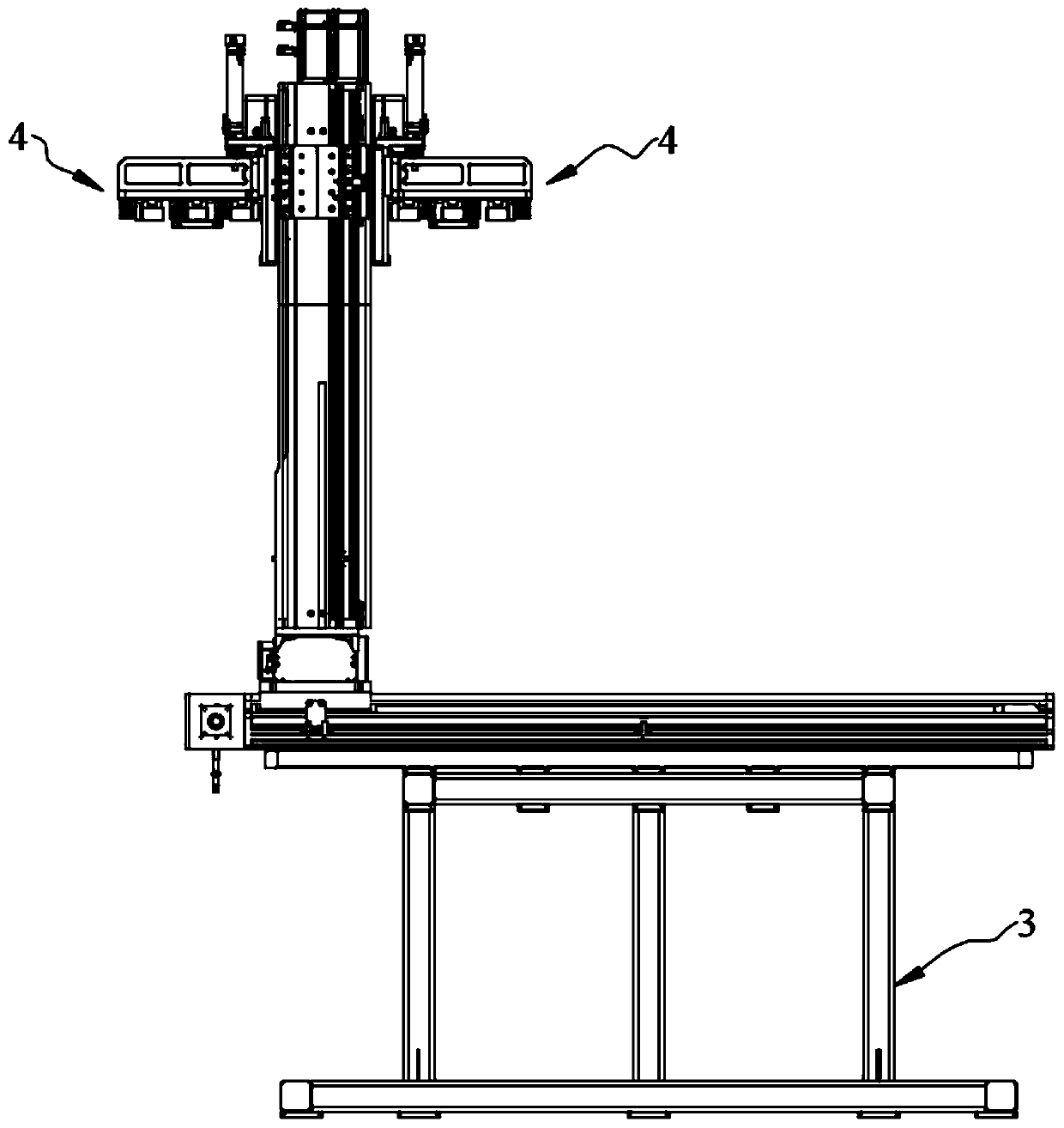

[0065] as attached Figure 3-4 As mentioned above, this embodiment is optimized as follows on the basis of Embodiment 1: the three-axis cantilever in step S2 includes X-axis guide rails 801, Y-axis guide rails 802, and Z-axis guide rails 803, all of which are equipped with ball screws. The lower end of the three-axis cantilever is provided with a bracket 3, the X-axis guide rail 801 is horizontally arranged on the upper end of the bracket 3, the Y-axis guide rail 802 is horizontally arranged on the upper end of the X-axis guide rail 801 and is perpendicular to the X-axis guide rail, and the Y-axis guide rail The lower end of the middle part of 802 is connected with the first sliding seat 8011, the first sliding seat 8011 is connected with the X-axis guide rail 801, the upper end of the Y-axis guide rail 802 is vertically connected with the Z-axis guide rail 803, and the lower end of the Z-axis guide rail 803 A second sliding seat 8021 is connected, and the second sliding seat ...

Embodiment 3

[0068] as attached Figure 5-6 As shown, this embodiment is based on Embodiment 2 and is optimized as follows: the Z-axis guide rail 803 is also connected with a third sliding seat 8031, and the jacking unit 4 is provided with two 803 is symmetrical, and the two jacking units 4 are connected to the third sliding seat 8031; the jacking unit 4 includes a laser sensor, a connecting plate 401, a jacking platform 403, a jacking rod 406 and a small cylinder 407, and the connection The plate 401 connects the jacking platform 403 and the third sliding seat 8031 with each other. The upper end of the jacking platform 403 is provided with a laser sensor, and the middle part of the lower end of the jacking platform 403 is provided with a lifting plate 405. There is a U-shaped draw-in slot, and the left and right sides of the lifting plate 405 are provided with jacking rods 406, and the front end of the lifting rods 406 is located in front of the front end of the jacking platform 403, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com