Auxiliary tightening device for automobile parts production

A technology for auto parts and skateboards is applied in the field of auxiliary tightening devices for auto parts production, which can solve the problems of manpower consumption and low efficiency, and achieve the effect of improving assembly efficiency and saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

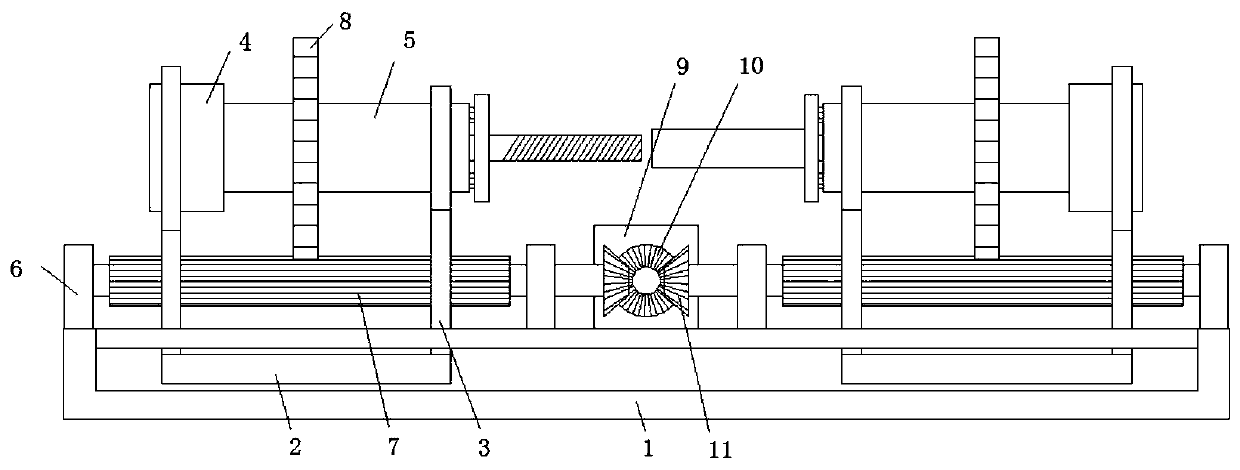

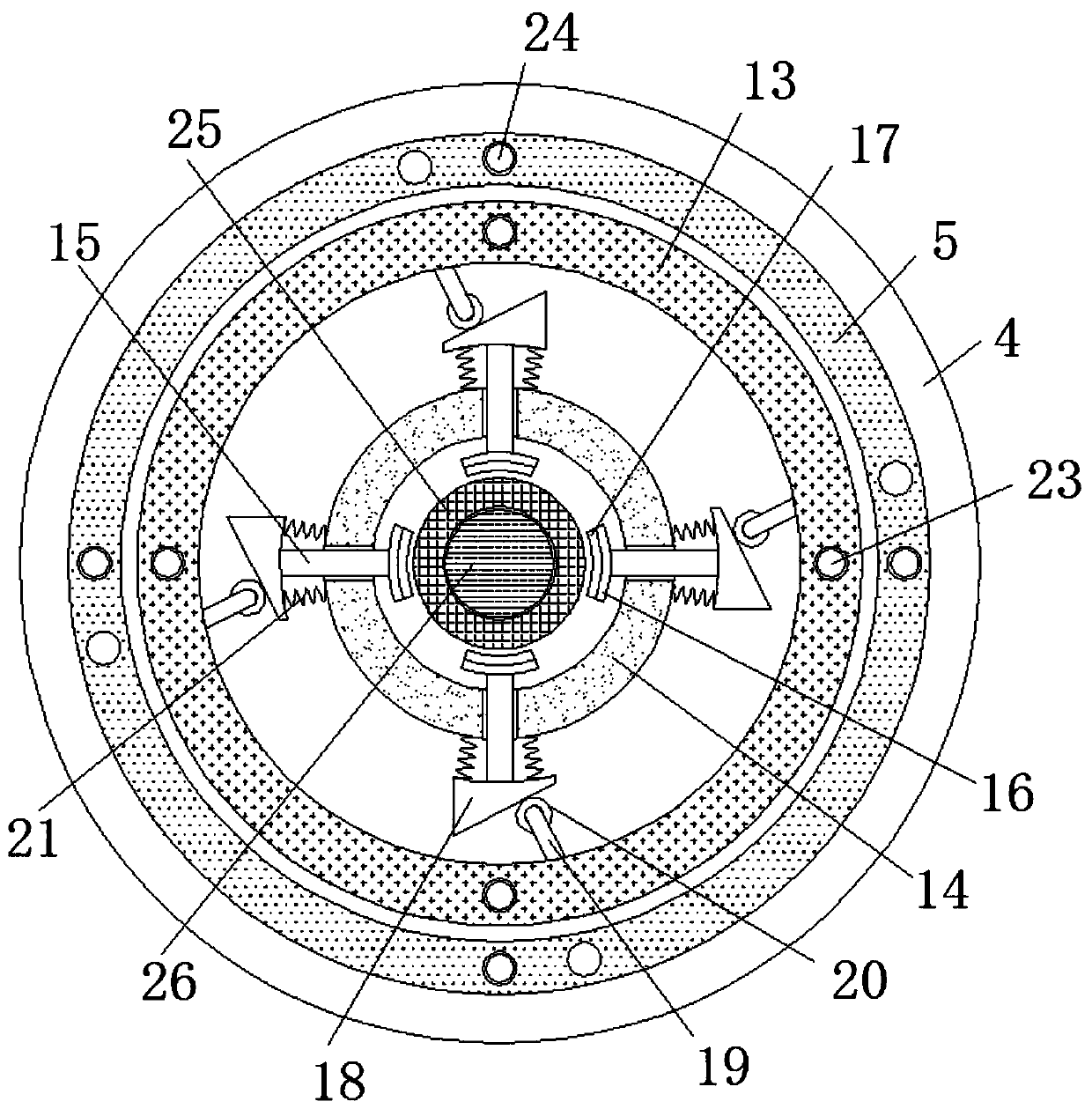

[0025] refer to Figure 1-4 , an auxiliary tightening device for the production of auto parts, comprising a device base 1, the device base 1 is provided with a horizontal chute, and a slide plate 2 is slidably connected in the horizontal chute, two slide plates 2 are arranged side by side, and the top sides of the slide plates 2 are Two rotating brackets 3 are fixedly arranged, and the top sides of the two rotating brackets 3 all extend to the vertical top of the device base 1, and the rotating frame is respectively provided with a vertical ring 4 and an outer cylinder 5, and one end of the outer cylinder 5 is connected to the vertical One side of the straight circular ring 4 is fixedly welded coaxially, the outside of the cylinder body of the outer cylinder 5 is fixedly covered with a transmission gear ring 8, the top side of the device base 1 is fixedly provided with a rotating seat 6, and the rotating seat 6 is connected with a transmission gear in rotation Column 7, transm...

Embodiment 2

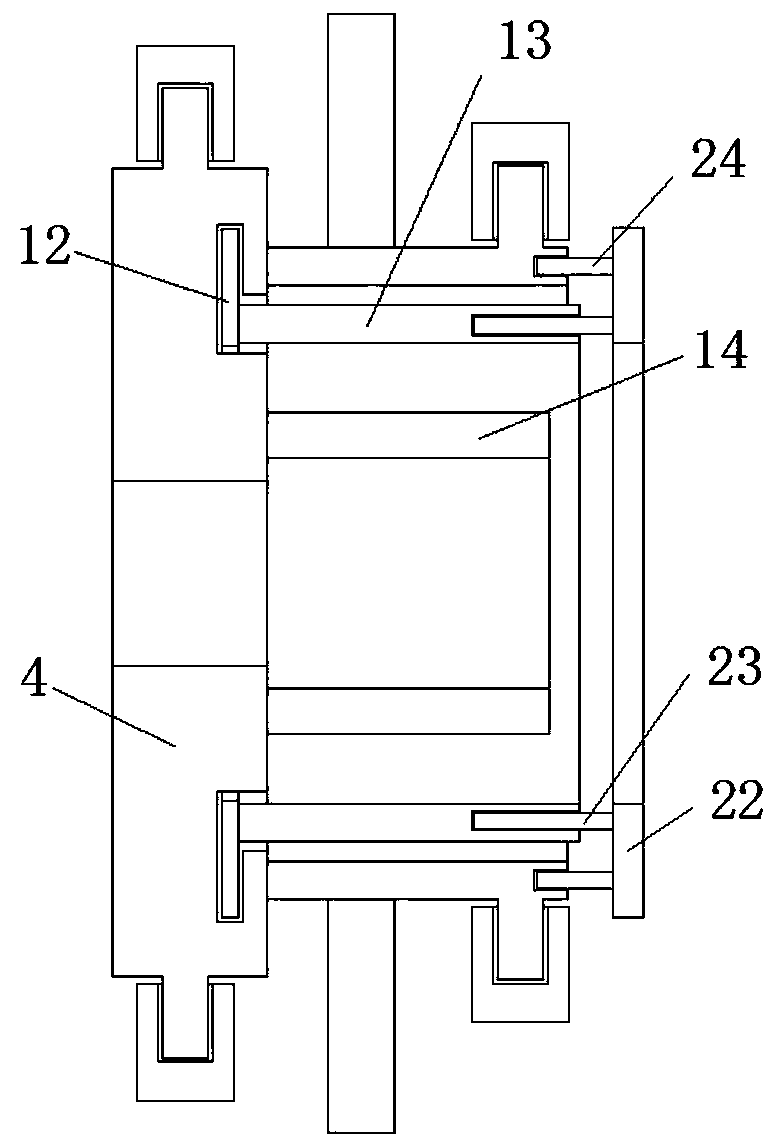

[0028] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the fixing mechanism includes a control ring 22, the control ring 22 is vertically arranged on the side of the outer cylinder 5 away from the vertical ring 4, and one side of the control ring 22 is fixed A long plunger 23 and a short plunger 24 are welded, and the side of the rotating inner cylinder 13 away from the vertical ring 4 is provided with a deep slot, one end of the long plunger 23 is stuck in the deep slot, and the outer cylinder 5 is far away from the vertical ring 4. One side of the straight ring 4 is provided with a shallow card slot, and one end of the short insertion rod 24 is clamped in the shallow card slot.

[0029] In this embodiment, the control ring 22 can control the relative position of the outer cylinder 5 and the rotating inner cylinder 13, and then control the relative position between the inclined contact plate 18 and the contact roller 20, thereb...

Embodiment 3

[0031] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 2. Preferably, there are several long insertion rods 23 and short insertion rods 24 respectively, and they are arranged on the same side of the control ring 22 in a circular equidistant manner, and there are several shallow card slots , and in groups of two by two, each group is set at a circular equidistant distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com