Silicon ingot grinding device

A technology of silicon ingots and mounting racks, which is applied in the directions of grinding machines, grinding slides, grinding racks, etc., can solve the problems of no auxiliary equipment, high grinding labor intensity, and can not meet production needs, so as to meet the needs of use and achieve rapid grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

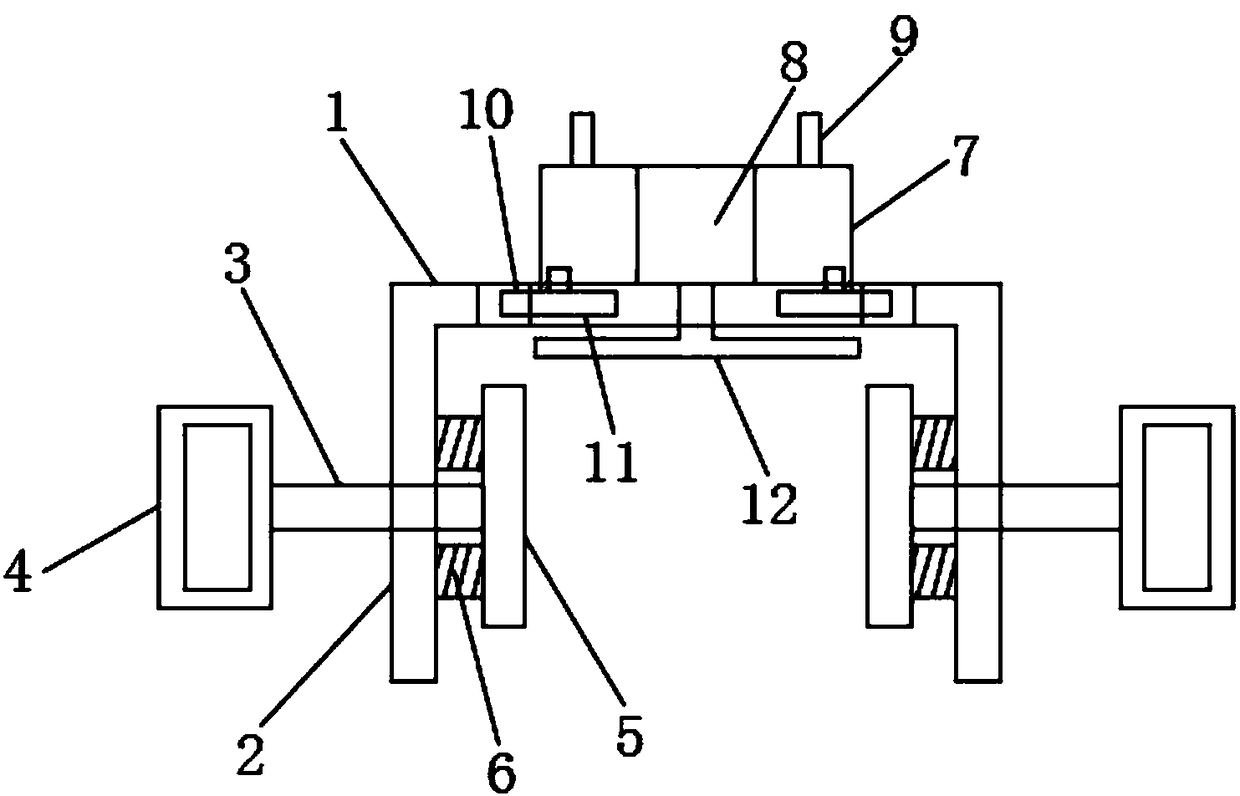

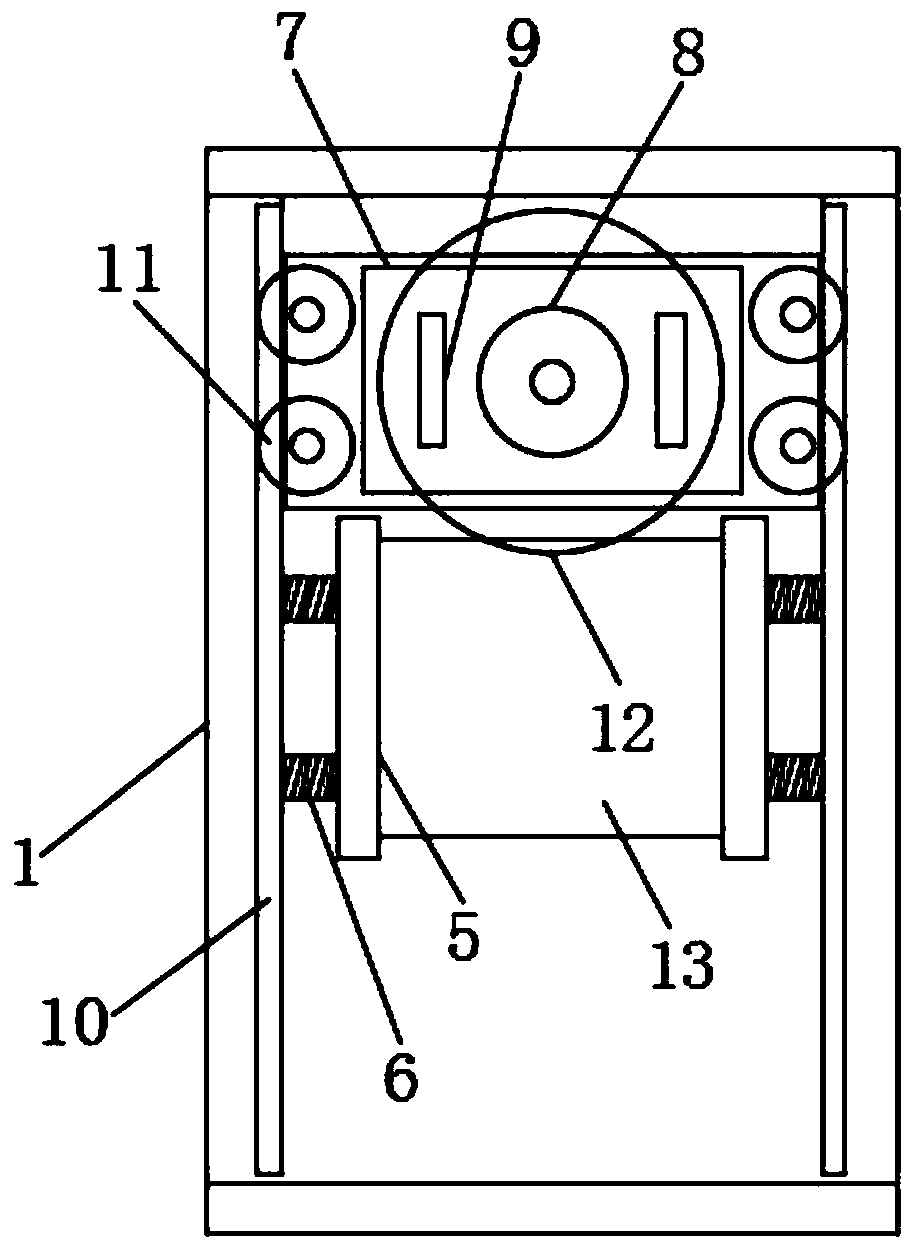

[0013] Such as Figure 1-2 It is a schematic diagram of the structure of the present invention, a silicon ingot grinding device, the two sides below the installation frame 1 of the device are support plates 2, and a motor 8 is placed on the installation frame 1, and a grinding sheet 12 is connected to the bottom of the motor 8.

[0014] When the motor 8 installed on the mounting frame 1 is powered on, the motor 8 drives the grinding sheet 12 connected to the motor shaft to work, and then the silicon ingot 13 placed in the middle of the mounting frame 1 is polished.

[0015] According to another embodiment of the present invention, it further includes that the motor 8 is installed and fixed in the housing 7, the lower part of the housing 7 is connected with the roller 11 through a connecting rod, the roller 11 is stuck in the roller groove 10 of the mounting frame 1, and the upper part of the housing 7 is fixed armrest9.

[0016] The motor 8 is fixed in the shell 7 by bolts, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap