A kind of high-sensitivity graphene flexible strain sensor and preparation method thereof

A strain sensor and high-sensitivity technology, which is applied in the field of material science, can solve problems such as high cost and unstable product performance, and achieve the effects of guaranteed fit, good conductivity, and good skin-friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

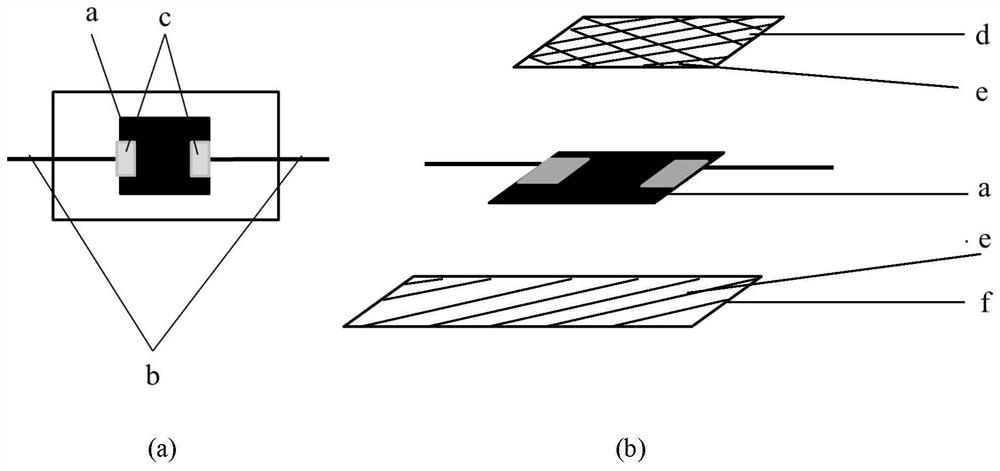

[0043] A high-sensitivity graphene flexible strain sensor, which is a flexible substrate f and a protective layer d oppositely arranged, and a sandwich structure of a graphene film a is arranged between the two, specifically comprising:

[0044] Flexible substrate f, the flexible substrate f is a flexible film coated with pressure-sensitive adhesive e on one side of the surface;

[0045] Protective layer d, the protective layer d is a flexible film coated with pressure-sensitive adhesive e on one side; the side of the protective layer d coated with pressure-sensitive adhesive e and the flexible substrate f coated with pressure-sensitive adhesive e One side opposite setting;

[0046] The graphene film a is set between the flexible substrate f and the protective layer d;

[0047] A pair of wires b are arranged at both ends of the graphene film a and fixed with conductive silver paste c.

[0048]The flexible film is a polyurethane film or a silicone film, the thickness of the f...

Embodiment 2

[0069] A kind of high-sensitivity graphene flexible strain sensor, its structure is the same as embodiment 1.

[0070] A preparation method for a high-sensitivity graphene flexible strain sensor, comprising the following steps:

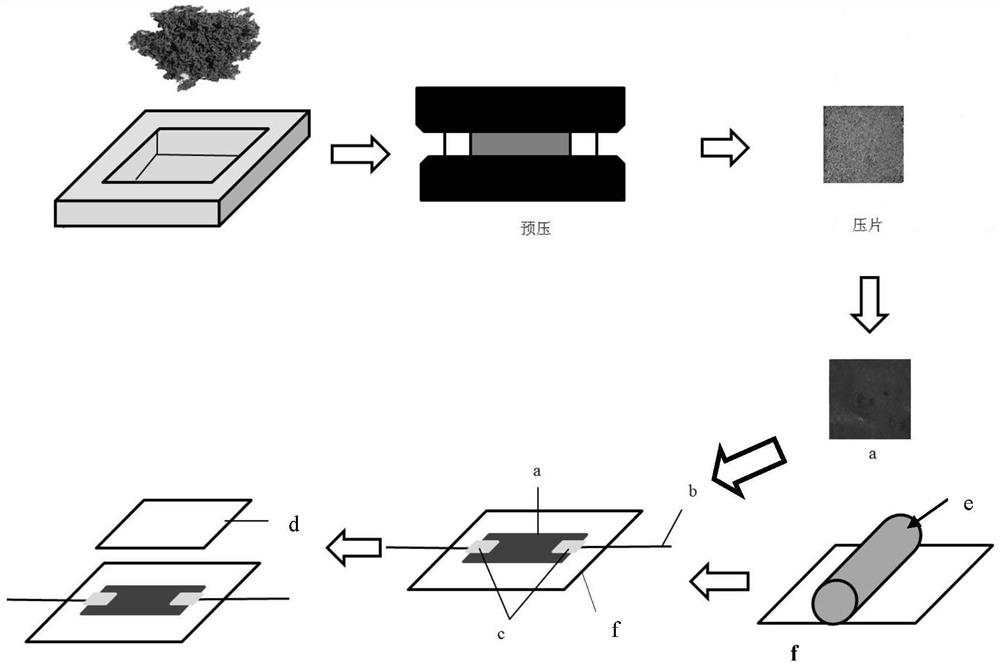

[0071] Step 1: Preparation of graphene film

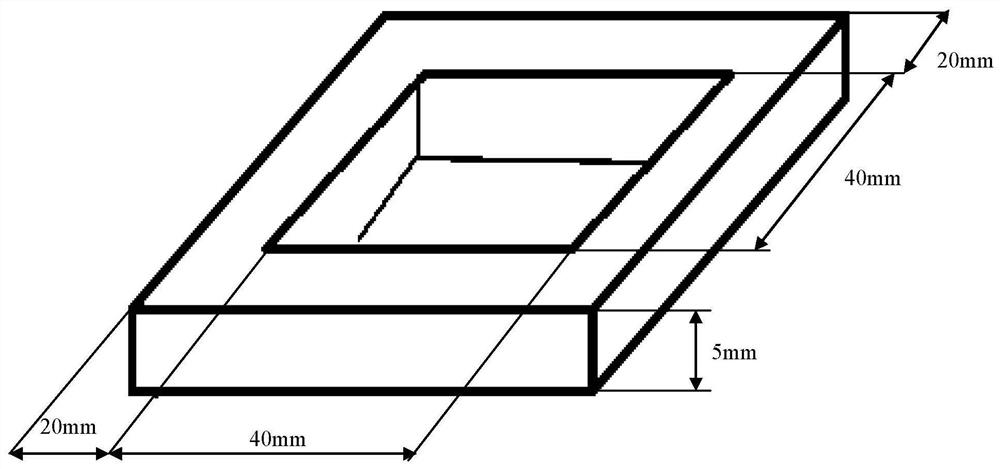

[0072] (1) Graphene flakes are put into the mold and pre-pressed, so that the graphene flakes are evenly dispersed, and the pre-pressed graphene flakes are obtained;

[0073] Described graphene sheet, its thickness is 2nm, is made of 3 layers of single-layer graphene, and its electric conductivity 1300S / cm;

[0074] The process conditions of the pre-pressing are: the pressure is 1200Pa, and the time is 12 seconds;

[0075] (2) adopt tablet press to carry out tableting to the pre-pressed graphene sheet, obtain graphene film; Wherein, the pressure of tabletting is 3MPa, and holding time is 30s, and the thickness of graphene film is 0.04mm;

[0076] Step 2:

[0077] (1) using a roller to evenly coat the s...

Embodiment 3

[0081] A kind of high-sensitivity graphene flexible strain sensor, its structure is the same as embodiment 1.

[0082] A preparation method for a high-sensitivity graphene flexible strain sensor, comprising the following steps:

[0083] Step 1: Preparation of graphene film

[0084] (1) Graphene flakes are put into a mold and pre-pressed, so that the graphene flakes are uniformly dispersed, and the graphene flakes obtained after pre-pressing are obtained; Composition, its conductivity is 1600S / cm;

[0085] The process conditions of the pre-pressing are: the pressure is 1300Pa, and the time is 10 seconds;

[0086] (2) adopt tablet press to carry out tableting to the pre-pressed graphene sheet, obtain graphene film; Wherein, the pressure of tabletting is 1MPa, and holding time is 90s, and the thickness of graphene film is 0.2mm;

[0087] Step 2:

[0088] (1) using a roller to evenly coat the surface of one side of the flexible film with a pressure-sensitive adhesive as the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com