Rotary filler biological membrane reactor

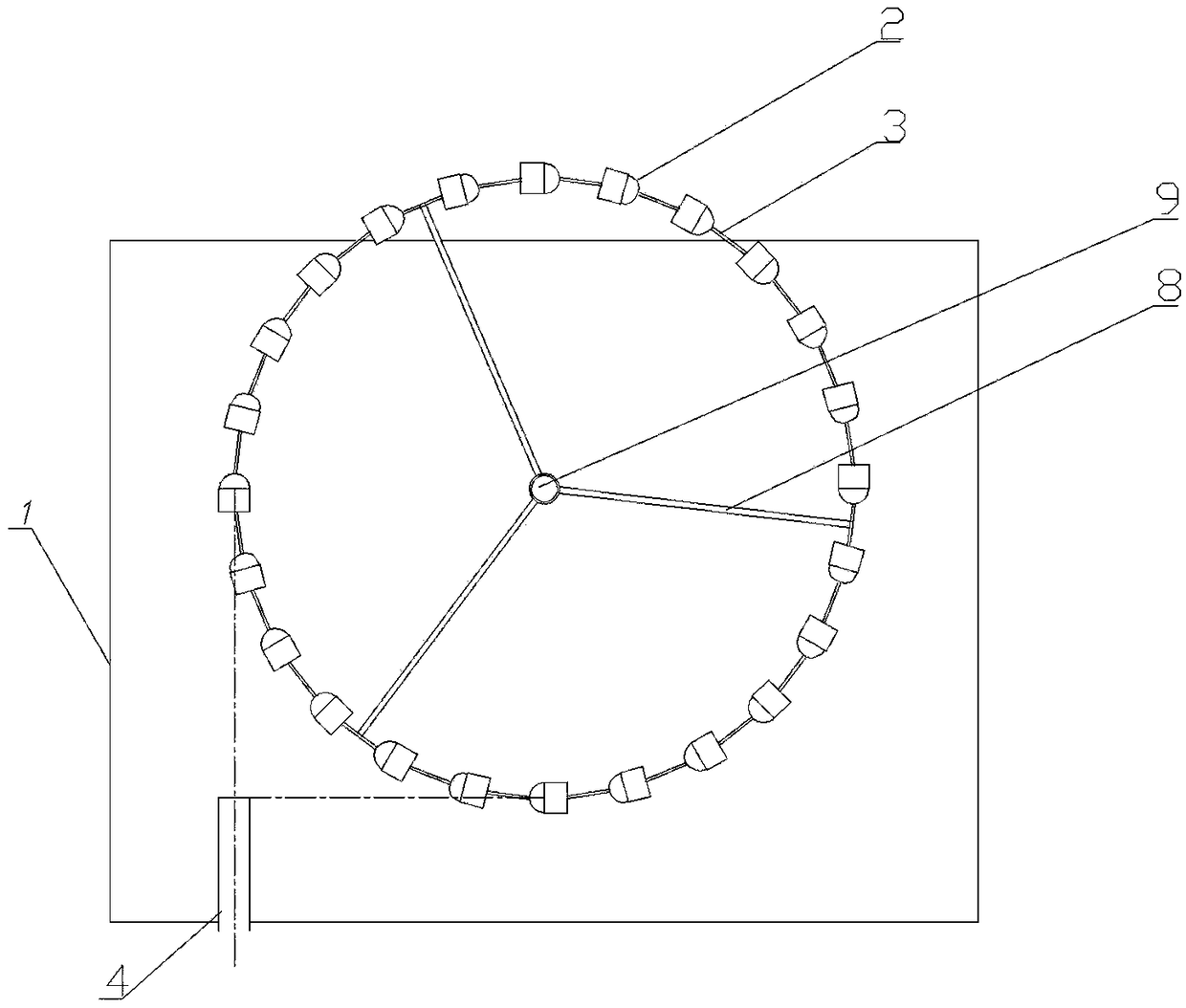

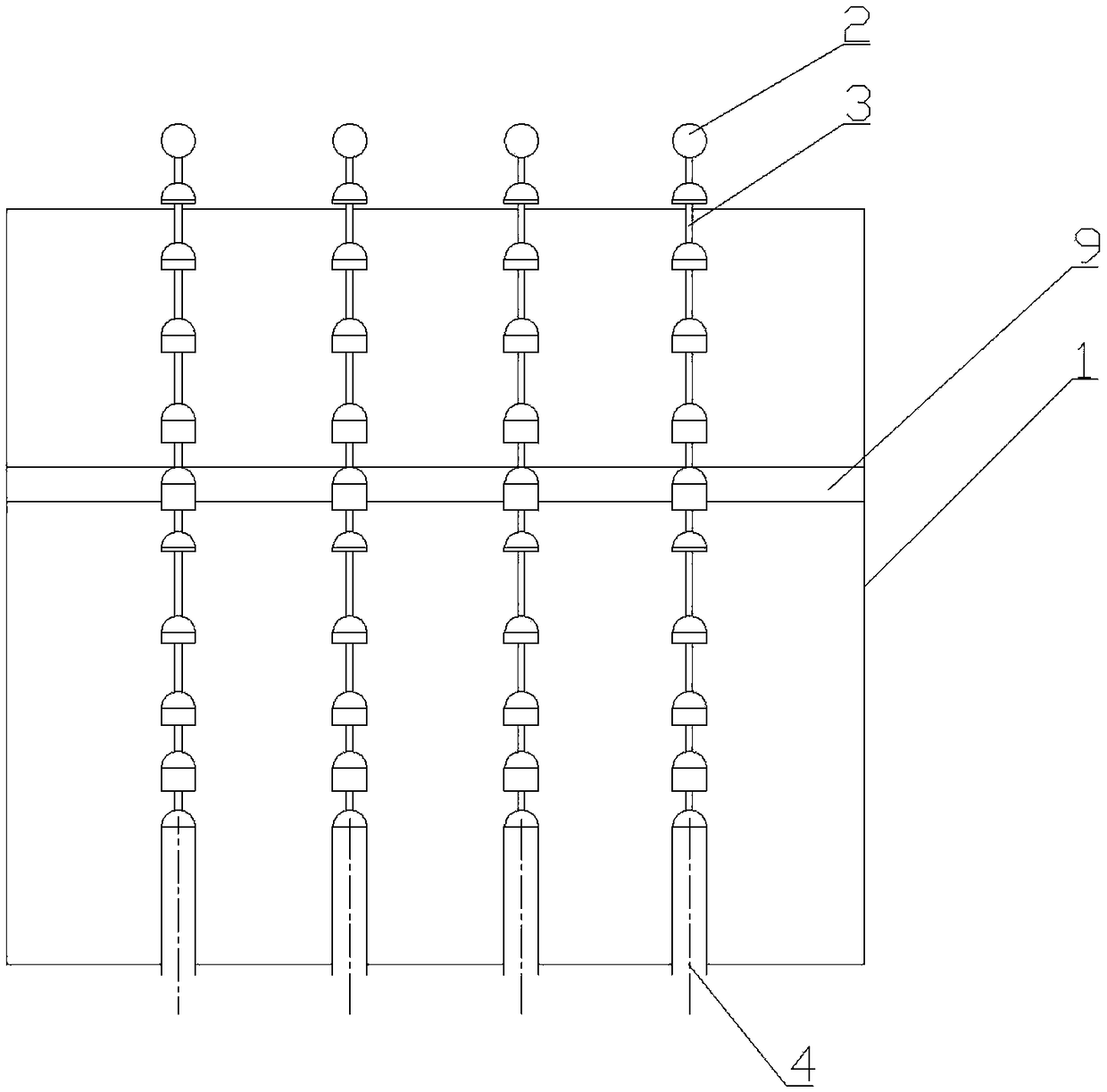

A biofilm reactor and rotary packing technology, applied in the field of water treatment, can solve problems such as uneven aeration, achieve high degradation efficiency, improve degradation efficiency, and improve capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

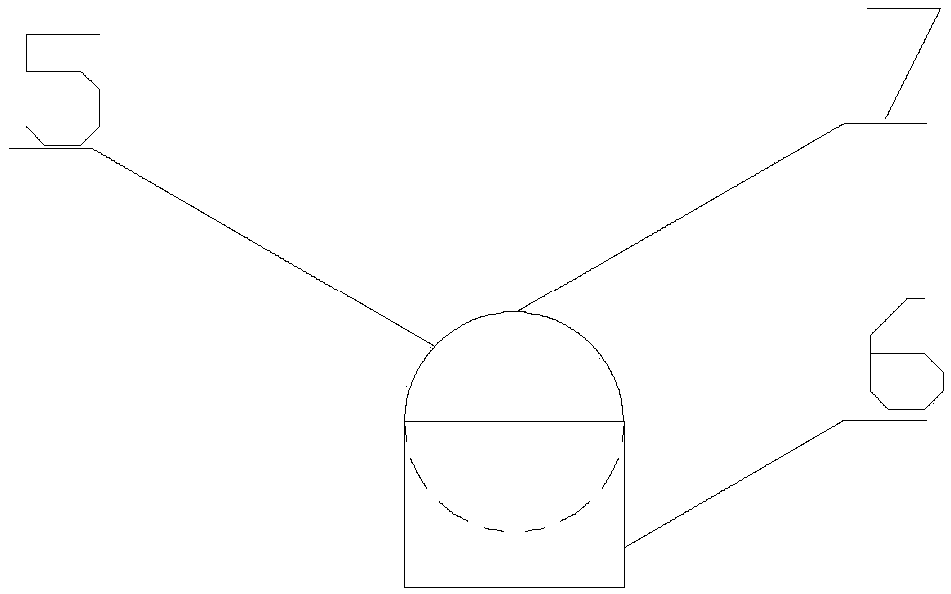

[0041] The preparation process of the magnetic spherical filler 5 is as follows:

[0042] Preparation of acid-modified biochar: place the biochar in hydrochloric acid or sulfuric acid with pH ≤ 4 to react, wash, and dry to obtain acid-modified biochar; the size of any one direction of the biochar is less than or equal to 0.5 cm; the The reaction time is 20-35 minutes, and the drying temperature is 50-80°C;

[0043] Preparation of mixed solution A: adding ferrous ions and ferric ions to water to obtain mixed solution A; the molar ratio of ferric ions to ferrous ions in the mixed solution A is 1.2-1.8.

[0044] Preparation of adsorbed Fe 2+ and Fe 3+ Biochar: add the acid-modified biochar into the mixed solution A, after stirring, after adsorption treatment and solid-liquid separation, the adsorption Fe 2+ and Fe 3+ of biochar; the preparation adsorbs Fe 2+ and Fe 3+ The stirring time in the biochar is 2-3 minutes, and the adsorption treatment time is 30-50 minutes;

[00...

Embodiment 1

[0054] Rotating packing biofilm reactor The material of the reactor housing 1 is stainless steel, the shape is circular, and the thickness is 5 mm. The diameter of the magnetic spherical packing 5 and the inner diameter of the hollow cylindrical magnetic packing 6 are both 4 cm; the height of the hollow cylindrical magnetic packing 6 is magnetic 1.3 times the diameter of the spherical packing 5. The glue used in the assembly of the rotary packing is polyvinyl alcohol adhesive. On the magnetic spherical packing 5, a cylindrical hole 7 with a diameter of 7 mm is opened along the centerline of the hollow cylindrical magnetic packing 6.

[0055] Magnetic spherical packing 5 is prepared as:

[0056] Preparation of acid-modified biochar: place the biochar in hydrochloric acid with a pH value of 4 to react, wash, and dry to obtain acid-modified biochar; the reaction time is 20 minutes, and the drying temperature is 50°C;

[0057] Preparation of mixed solution A: adding ferrous ions...

Embodiment 2

[0069] The material of the shell 1 of the rotating packing biofilm reactor is plexiglass, the shape is square, and the thickness is 10 mm. The diameter of the magnetic spherical packing 5 and the inner diameter of the hollow cylindrical magnetic packing 6 are both 7 cm; the height of the hollow cylindrical magnetic packing 6 is magnetic 1.5 times the diameter of the spherical packing 5. The glue used in the assembly of the rotary packing is polyvinyl formal glue. On the magnetic spherical packing 5, a cylindrical hole 7 with a diameter of 11 mm is opened along the centerline of the hollow cylindrical magnetic packing 6.

[0070] Magnetic spherical packing 5 is prepared as:

[0071] Preparation of acid-modified biochar: place the biochar in sulfuric acid with a pH value of 3 to react, wash, and dry to obtain acid-modified biochar; the reaction time is 35 minutes, and the drying temperature is 80°C;

[0072] Preparation of mixed solution A: adding ferrous ions and ferric ions ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com