Thermal insulation device for belt type polymerization

A technology of heat preservation device and polymer, applied in the field of heat preservation device, can solve the problems of inability to maintain a higher temperature in the polymer body, inconspicuous heat preservation effect of a heat preservation cover, low conversion rate of polymerization reaction, etc. Insulation effect, sufficient effect of polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

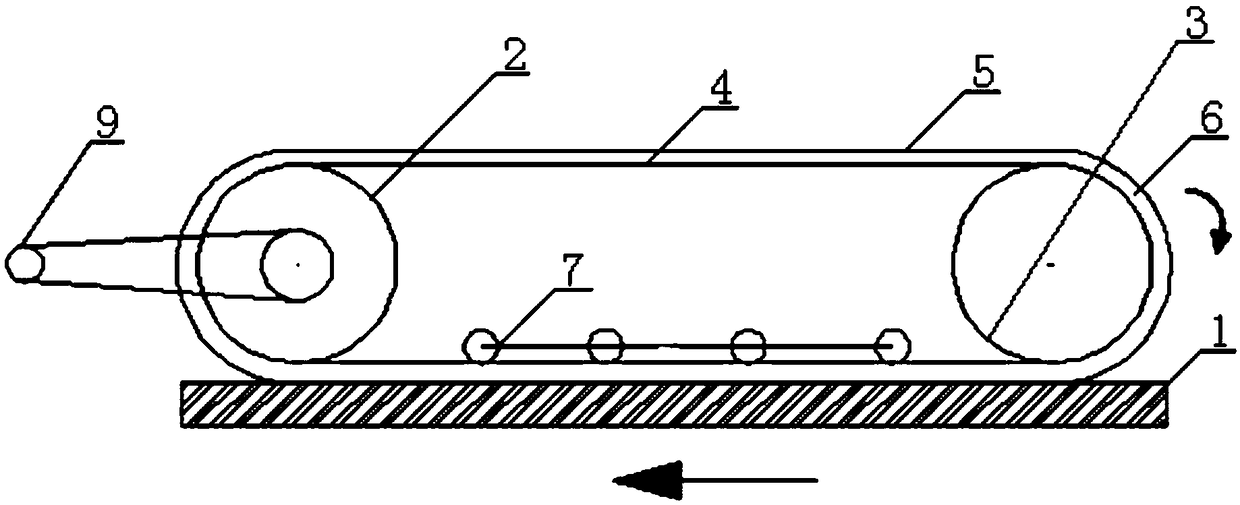

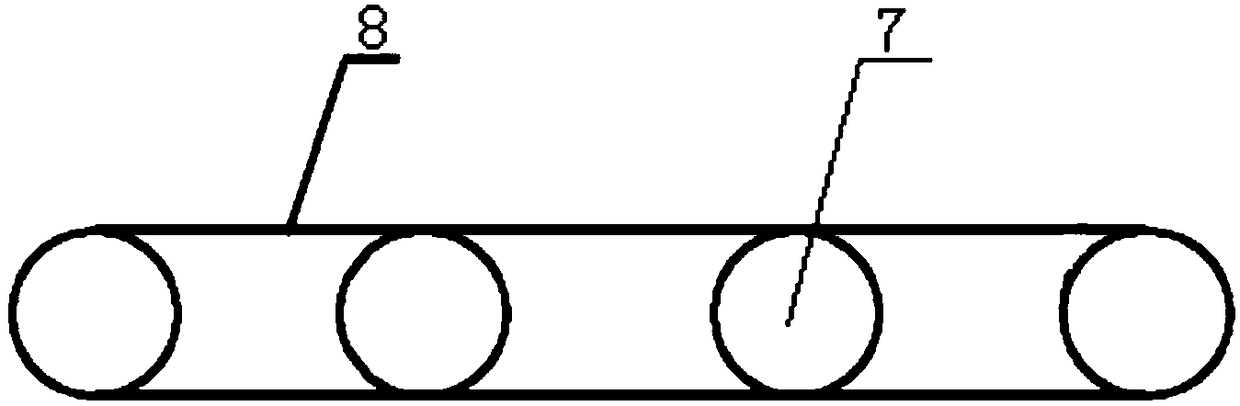

[0033] Add 2685kg of acrylamide (40%), 400kg of acryloyloxyethyltrimethylammonium chloride (80%), 1380kg of deionized water, and 0.45kg of azo initiator into the reactor and mix well, adjust the pH with citric acid or sulfuric acid to 4-5, lower the temperature to 4°C, and continuously feed the material to the polymerization belt after deoxygenation, enter the heat preservation zone to form solid polymer 1 and reach the highest temperature of 89.6°C, the forward speed of the polymerization belt is 0.5m / min, when only ordinary heat preservation When the cover heats the polymer 1, the temperature of the solid polymer 1 at the outlet is 69.3°C. After using the belt type polymerization heat preservation device of the present invention, the temperature of the solid polymer 1 at the outlet is 78.7°C.

Embodiment 2

[0035] With highly active methacryloyloxyethyltrimethylammonium chloride (80%) 3500kg, deionized water 500kg, azobisisobutylimidazoline hydrochloride 2kg, 2,4,6 (trimethylbenzyl Acyl)diphenylphosphine oxide 2kg, ethylene glycol dimethacrylate 0.3g, disodium ethylenediaminetetraacetate 1.5kg were added to the reaction kettle and mixed evenly, and adipic acid was used to adjust the pH to 3.5. Feed to the polymerization belt, enter the heat preservation zone to form solid polymer 1 and reach the highest temperature of 83.5 ° C, the forward speed of the polymerization belt is 0.3m / min, when only the ordinary heat preservation cover keeps the polymer 1 warm, the solid polymer 1 at the exit The temperature of 1 is 62.6°C. After using the belt-type polymerization heat preservation device of the present invention, the temperature of solid polymer 1 at the outlet is 72.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com