Composite lithium-based lubricating grease and preparation method thereof

A technology of complex lithium base and base grease, which is applied in lubricating compositions, petroleum industry and other directions, can solve the problems of poor corrosion resistance, poor water resistance, complicated preparation process and operation, and achieves improved water resistance, strong water resistance, and the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

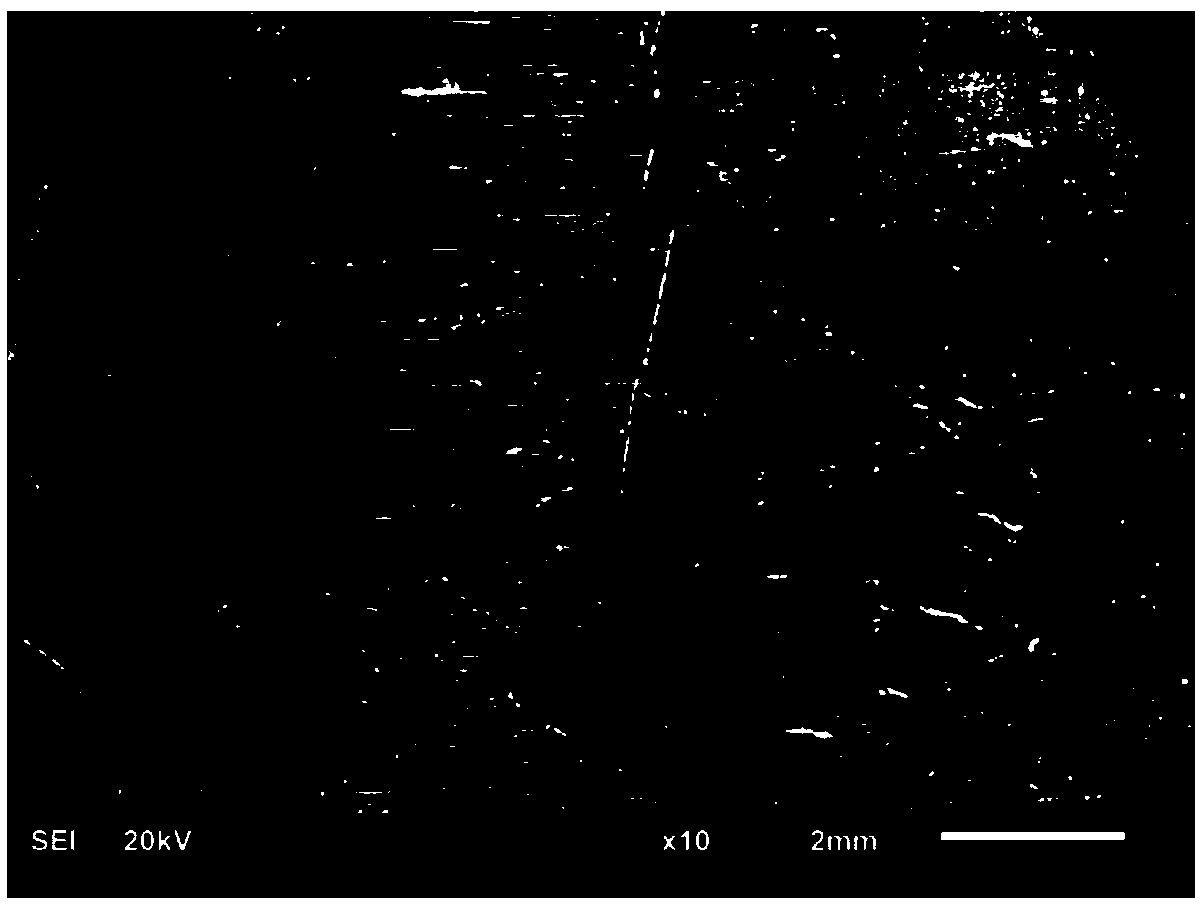

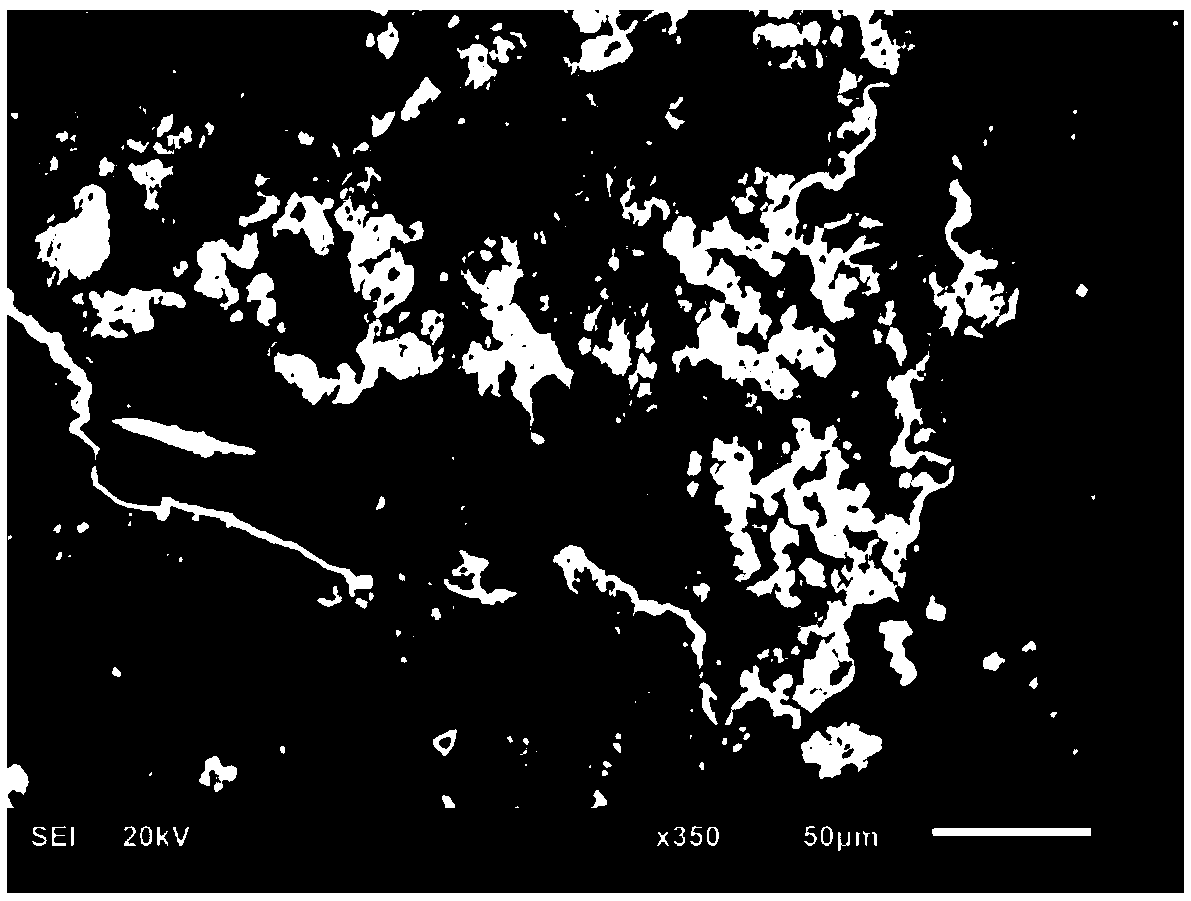

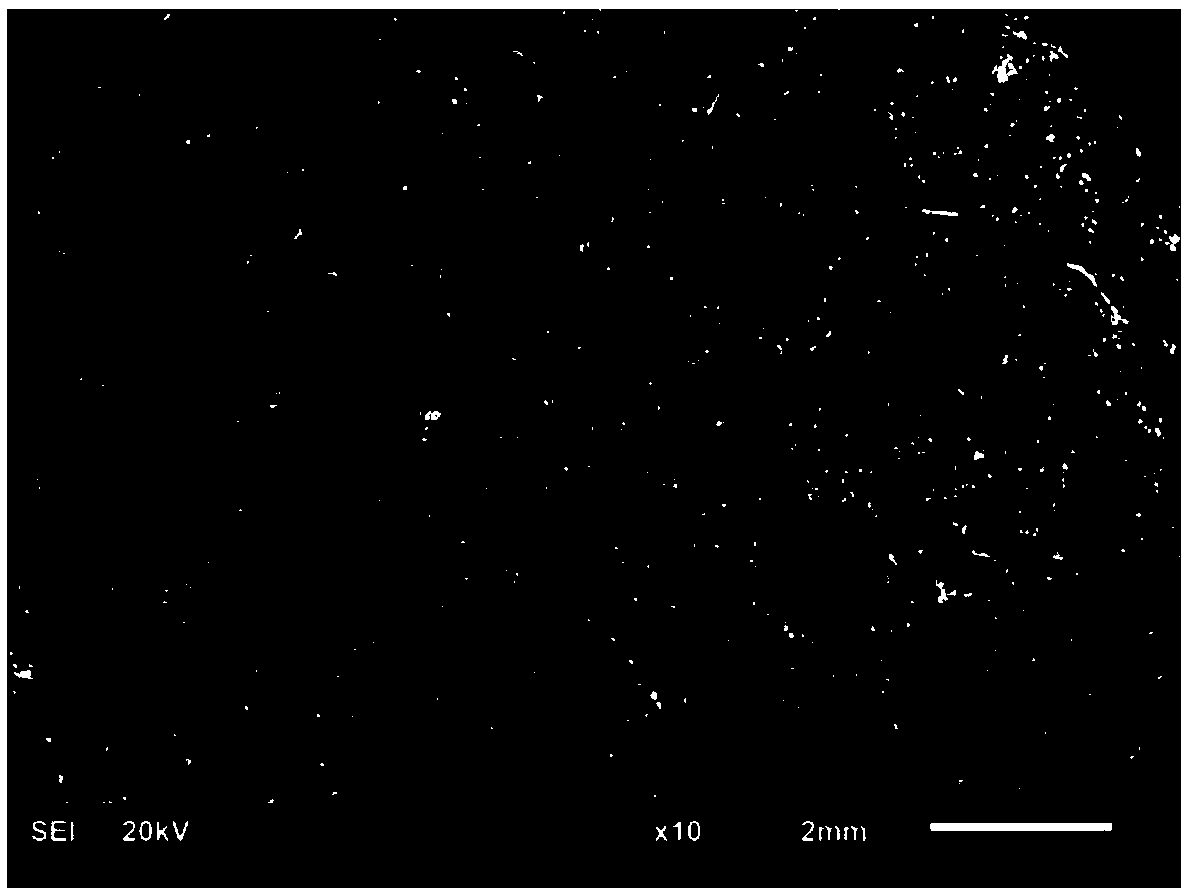

Image

Examples

Embodiment 1

[0029] A lithium complex grease comprises the following components in parts by weight: 70 parts of vegetable oil, 4.5 parts of lauryl hydroxystearic acid, 0.8 parts of sebacic acid and 0.3 parts of LiOH aqueous solution.

[0030] Wherein, LiOH aqueous solution is made by mixing LiOH and water according to the weight ratio of 1:3.

[0031] The preparation method of above-mentioned composite lithium grease, comprises the following steps:

[0032] (1) First heat 42 parts by weight of vegetable oil to 75°C, then add lauryl hydroxystearic acid, continue to heat up to 120°C, then add sebacic acid and stir until completely dissolved, then cool down to 95°C;

[0033] (2) LiOH aqueous solution was added dropwise to the resultant of step (1), and the addition was completed within 30 minutes, then the temperature was raised to 110° C., and the temperature was kept for 1 hour;

[0034] (3) Add the remaining vegetable oil to the resultant of step (2), then raise the temperature to 200°C, ...

Embodiment 2

[0036] A lithium complex grease comprises the following components in parts by weight: 90 parts of mineral oil, 30.7 parts of decahydroxystearic acid, 9.4 parts of phthalic acid and 4.8 parts of LiOH aqueous solution.

[0037] Wherein, LiOH aqueous solution is made by mixing LiOH and water according to the weight ratio of 1:3.

[0038] The preparation method of above-mentioned composite lithium grease, comprises the following steps:

[0039] (1) First, 54 parts by weight of mineral oil are heated to 85°C, then decahydroxystearic acid is added, the temperature is continued to rise to 130°C, then phthalic acid is added and stirred until completely dissolved, and then the temperature is lowered to 105°C;

[0040] (2) LiOH aqueous solution was added dropwise to the resultant of step (1), and the addition was completed within 35 minutes, then the temperature was raised to 120° C., and the temperature was kept for 1 hour;

[0041] (3) Add the remaining mineral oil to the resultant ...

Embodiment 3

[0043] A lithium complex grease comprises the following components in parts by weight: 84 parts of synthetic oil, 5.2 parts of lauryl hydroxystearic acid, 3.6 parts of adipic acid and 0.8 parts of LiOH aqueous solution.

[0044] Wherein, LiOH aqueous solution is made by mixing LiOH and water according to the weight ratio of 1:3.

[0045] The preparation method of above-mentioned composite lithium grease, comprises the following steps:

[0046] (1) First heat 51 parts by weight of synthetic oil to 80°C, then add lauryl hydroxystearic acid, continue to heat up to 125°C, then add adipic acid and stir until completely dissolved, then cool down to 100°C;

[0047] (2) LiOH aqueous solution was added dropwise to the resultant of step (1), and the addition was completed within 40 minutes, then the temperature was raised to 115° C., and the temperature was kept for 1 hour;

[0048] (3) Add the remaining synthetic oil to the product of step (2), then raise the temperature to 205°C, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com