Camellia seed cold pressing oil producing technology

A camellia seed, cold pressing technology, applied in the direction of oil/fat refining, oil/fat production, fat production, etc. Oil rate and purity and other issues, to achieve the effect of promoting oil extraction, improving market competitiveness, and improving oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

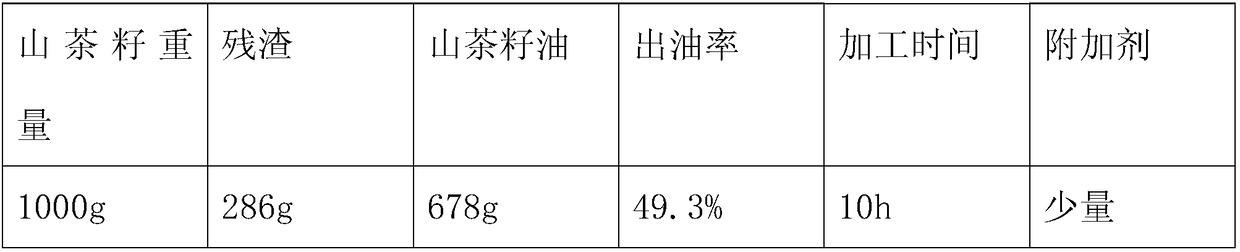

Problems solved by technology

Method used

Image

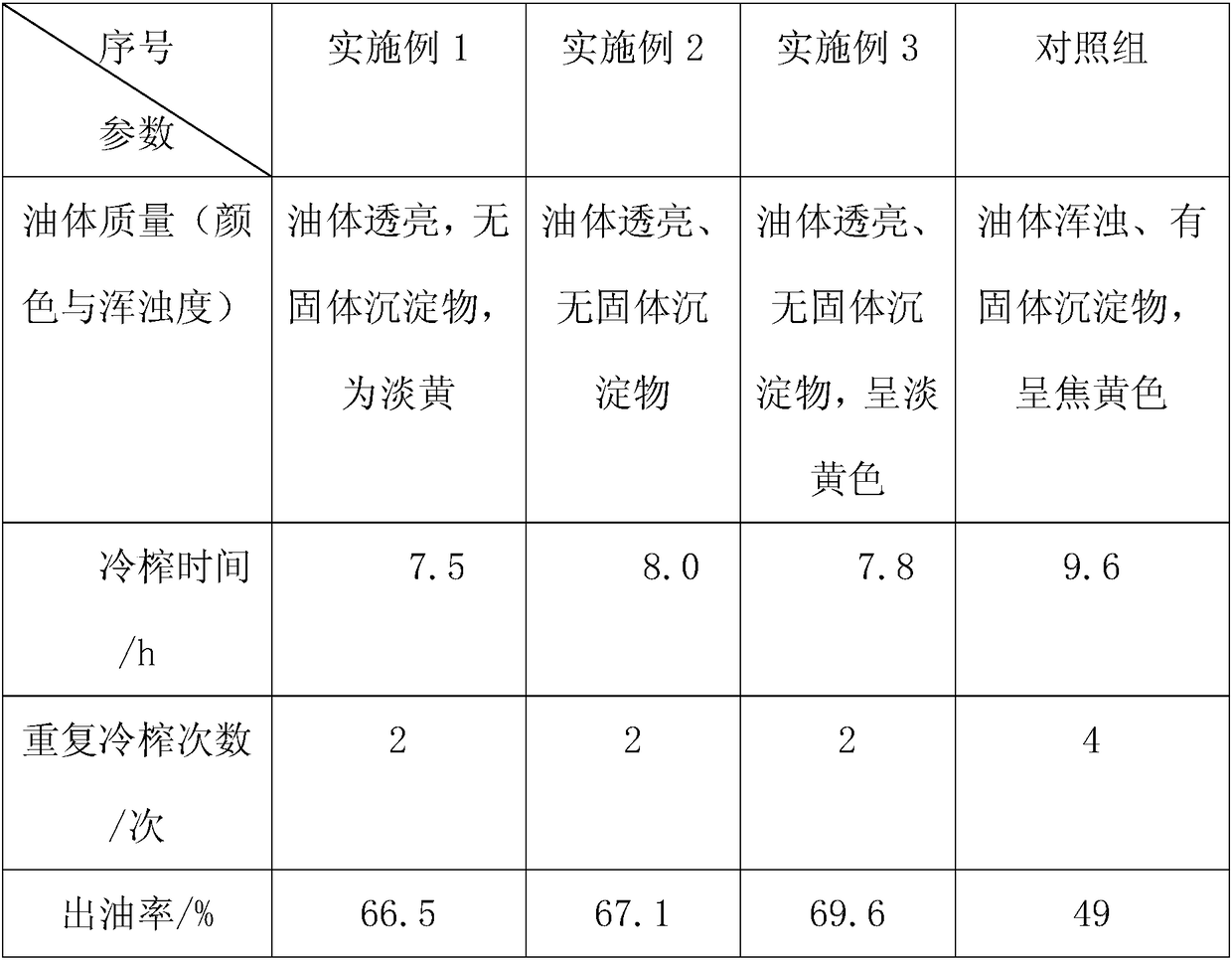

Examples

Embodiment 1

[0026] A cold-pressing oil-making process of camellia oleifera seeds, comprising the following production steps,

[0027] 1) Select 100kg of Camellia oleifera seeds, clean them of impurities, and screen the Camellia oleifera seeds with full particles and no insect eyes; in the process of cleaning impurities, select a sieve with an aperture of 4.2mm×15mm, and the diameter of the sieve surface is controlled at 2.4cm.

[0028] 2) Dipping: put the rapeseed prepared in step 1) into a sealed tank after vacuum disinfection, then add the mixed solution into the sealed tank, soak the rapeseed for 1.0 h in the sealed tank with the mixed solution, and take out the camellia oleifera Seeds are dried after being drained, and the moisture content of the dried Camellia oleifera seeds is lower than 45% for later use;

[0029] Wherein, the mixed solution is prepared according to the weight ratio of cell wall breaking enzyme:acid protease:alkaline protease:deionized water=4:2:1:20. The preparat...

Embodiment 2

[0040] A cold-pressing oil-making process of camellia oleifera seeds, comprising the following production steps,

[0041] 1) Select 200 kg of camellia oil seeds, clean up impurities on the camellia oleifera seeds, and screen the camellia oleifera seeds with full particles and no worm eyes; in the process of cleaning up impurities, the present invention selects a sieve with an aperture of 4.2mm×15mm, and the diameter of the sieve surface is 4.6 mm. cm.

[0042] 2) Dipping: put the rapeseed prepared in step 1) into a sealed tank after vacuum disinfection, then add the mixed solution into the sealed tank, soak the rapeseed in the sealed tank with the mixed solution for 3.5 hours, and take out the camellia oleifera Seeds are dried after being drained, and the moisture content of the dried Camellia oleifera seeds is lower than 45% for later use;

[0043] Wherein, the mixed solution is prepared according to the weight ratio of cell wall breaking enzyme:acid protease:alkaline protea...

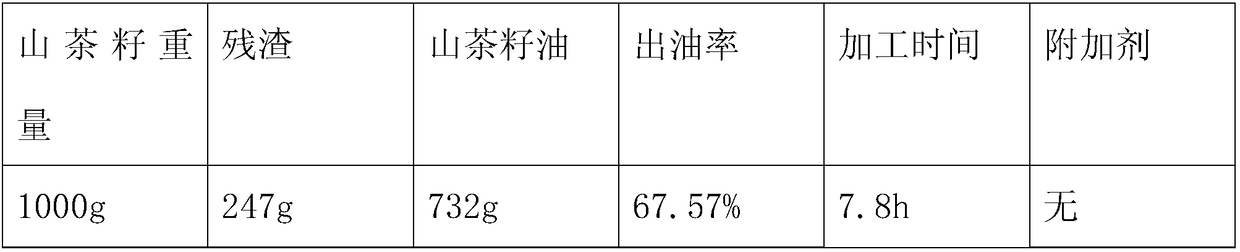

Embodiment 3

[0054] A cold-pressing oil-making process of camellia oleifera seeds, comprising the following production steps,

[0055] 1) Select 150kg of camellia oleifera seeds, clean the camellia oleifera seeds from impurities, and screen the camellia oleifera seeds with full particles and no insect eyes; in the process of cleaning impurities, select a sieve with an aperture of 4.2mm×15mm, and the diameter of the sieve surface is 4.3cm.

[0056] 2) Dipping: put the rapeseed prepared in step 1) into a sealed tank after vacuum disinfection, then add the mixed solution into the sealed tank, soak the rapeseed in the sealed tank with the mixed solution for 3.2 hours, and take out the camellia oleifera Seeds are dried after being drained, and the moisture content of the dried Camellia oleifera seeds is lower than 45% for later use;

[0057] Wherein, the mixed solution is prepared according to the weight ratio of cell wall breaking enzyme:acid protease:alkaline protease:deionized water=5:6:4:21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com