Processing method of fermented black tea

A processing method and technology of black tea, which is applied in the field of fermented black tea processing, can solve the problems of affecting tea shape and poor cellulase cell rupture effect, and achieve the effects of water balance, fermentation process optimization, and accelerated rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

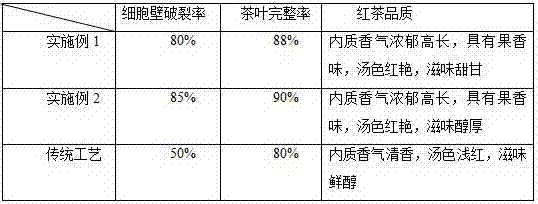

Examples

Embodiment 1

[0015] Embodiment 1: a kind of processing method of fermented black tea, comprises selecting leaf and spreading operation, withering operation, kneading operation, fermenting operation and drying operation, concrete operations are as follows:

[0016] a. Leaf selection and drying process: pick fresh tea leaves from big tree tea with one bud and two leaves or one bud and three leaves in a tea garden above 800 meters above sea level, and place the fresh leaves on a drying rack with a thickness of 2 ~5cm, spread out in the weak sunlight for 0.50~1h;

[0017] b. Withering process: placing the tea leaves that have been selected and aired in a withering tank for hot air withering, the temperature of the hot air is 40-60°C, and the withering time is 1-4 hours to obtain withered leaves;

[0018] d, kneading process: put the withered leaves through step b into a kneading machine, and knead them three times to shape. When kneading empty, put the withered leaves on the kneading machine, ...

Embodiment 2

[0023] Embodiment 2: a kind of processing method of fermented black tea, comprises selecting leaf and spreading operation, withering operation, kneading operation, fermenting operation and drying operation, concrete operations are as follows:

[0024] a. Leaf selection and drying process: pick fresh tea leaves from big tree tea with one bud and two leaves or one bud and three leaves in a tea garden above 800 meters above sea level, and place the fresh leaves on a drying rack with a thickness of 2 ~5cm, spread out in the weak sunlight for 0.50~1h;

[0025] b. Withering process: placing the tea leaves that have been selected and aired in a withering tank for hot air withering, the temperature of the hot air is 40-60°C, and the withering time is 1-4 hours to obtain withered leaves;

[0026] d, kneading process: put the withered leaves through step b into a kneading machine, and knead them three times to shape. When kneading empty, put the withered leaves on the kneading machine, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com