Horizontal construction joint reinforcing bolt and reinforcing method based on bolt

A technology of horizontal construction joints and bolts, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and on-site preparation of building components. The system lacks problems such as the connection of the old wall structure to achieve the effect of reducing construction slag, ensuring the smoothness of the wall surface, and good quality of one-time molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

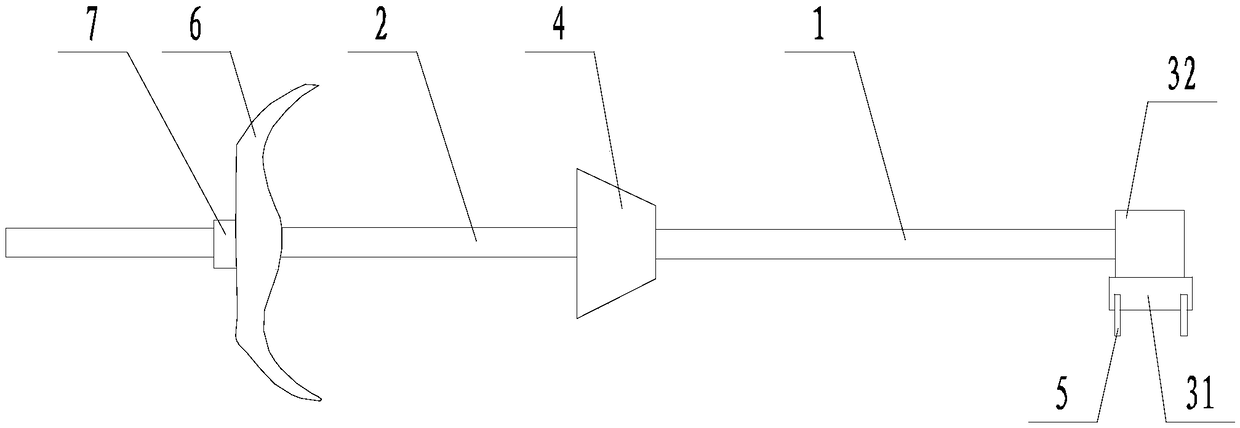

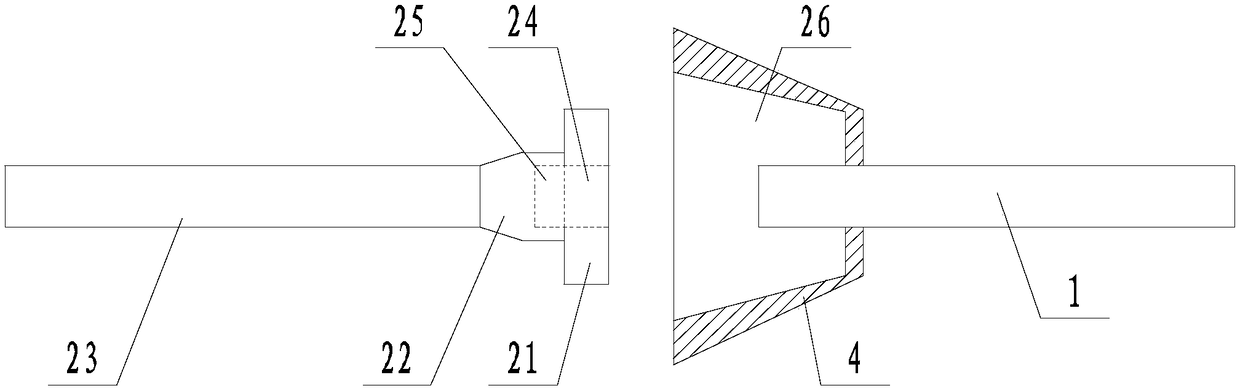

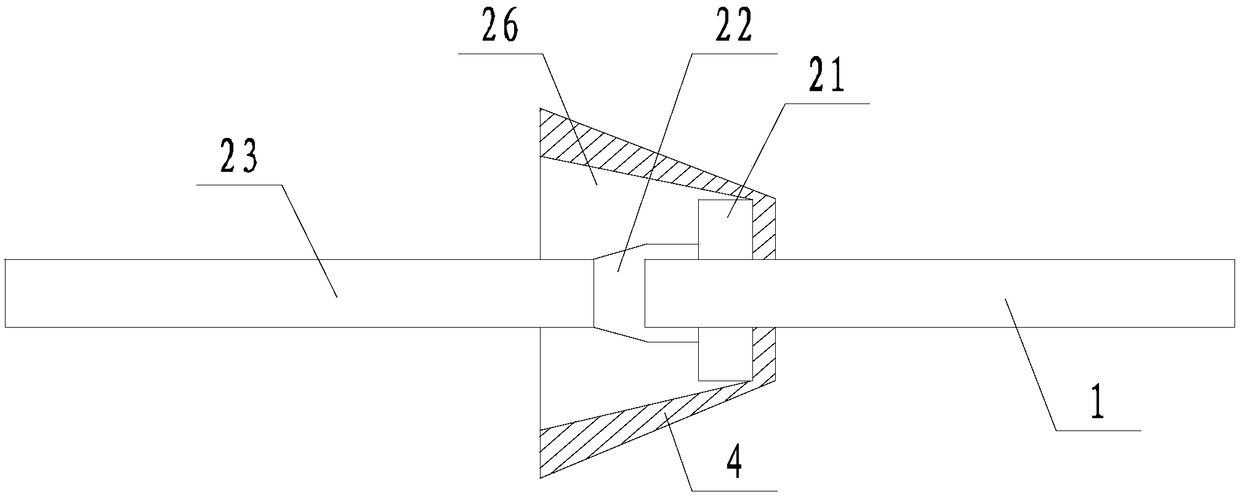

[0041] Such as Figure 1 to Figure 3 A horizontal construction joint reinforcement bolt shown includes a wall inner section screw 1, and the two ends of the wall inner section screw 1 are respectively threaded with the wall outer section screw 2 and the wall fixing part 3; the wall outer section screw 2 includes a base part 21, a base part 22, and a screw part 23 connected in sequence, the outer diameter of the base part 21 is larger than the outer diameter of the base part 22, a threaded hole 24 is set on the base part 21, and a threaded hole 24 is set on the base part 22 The threaded groove 25 communicated with the threaded hole 24, the threaded hole 24, the threaded groove 25 are all coaxial with the screw part 23, and the threaded hole 24, the threaded groove 25 are all matched with the section screw rod 1 in the wall; A tapered sleeve 4 is sheathed on the screw rod 1 of the inner section of the wall, and the tapered sleeve 4 is coaxial with the screw rod 1 of the inner se...

Embodiment 2

[0043] Such as Figure 1 to Figure 3 Shown is a horizontal construction joint reinforcement bolt. On the basis of Embodiment 1, the wall-connecting fixture 3 includes a bottom plate 31 and a protrusion 32 fixed on the bottom plate 31. The protrusion 32 is arranged on the wall and The screw 1 in the wall is inserted into the threaded hole; the screw 5 is fixedly connected with the bottom plate 31, and the screw 5 extends from the side of the bottom plate 31 away from the direction where the protrusion 32 is located. out. The groove 26 is tapered from the open end to the bottom end, the aperture gradually decreases, and the bottom end of the groove 26 matches the base part 21; when the base part 21 is located at the bottom end of the groove 26, Both the base part 21 and the base part 22 are located in the groove 26 . The mountain-shaped pipe clip 6 is movably sleeved on the screw rod 2 of the outer section of the wall, and the mountain-shaped pipe clip 6 is used to clamp the m...

Embodiment 3

[0045] A method for reinforcing horizontal construction joints, such as Figure 1 to Figure 8 As shown, the following steps are included: (a) Connect the screw 1 of the inner section of the wall and the fixing part 3 of the wall, and pre-embed them in the old wall 12 in advance, so that one end of the screw 1 of the inner section of the wall enters the tapered sleeve 4 1. The open end of the tapered sleeve 4 is positioned at the side of the old wall; (b) cleans up the old wall and sets out the wires on the old wall; binds the wall reinforcement, installs water and electricity pipelines and embedded parts, and completes the hidden project; (c) installs the inside The shear wall formwork 10 is placed vertically on the wall reinforcement, and a tongue and groove steel plate 8 is installed on the inner side of the top of the outer shear wall formwork 11. The groove area is located below the construction joint, and the sponge strip 9 on the outer shear wall formwork 11 is pasted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com