Targeted acidification fracturing physical simulation method for pore-type carbonate rock and application

A carbonate rock and physical simulation technology, applied in the field of oil and gas exploration, can solve problems such as unfavorable simulation tests, difficulties in sampling underground cavernous carbonate rocks, and inability to ensure structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

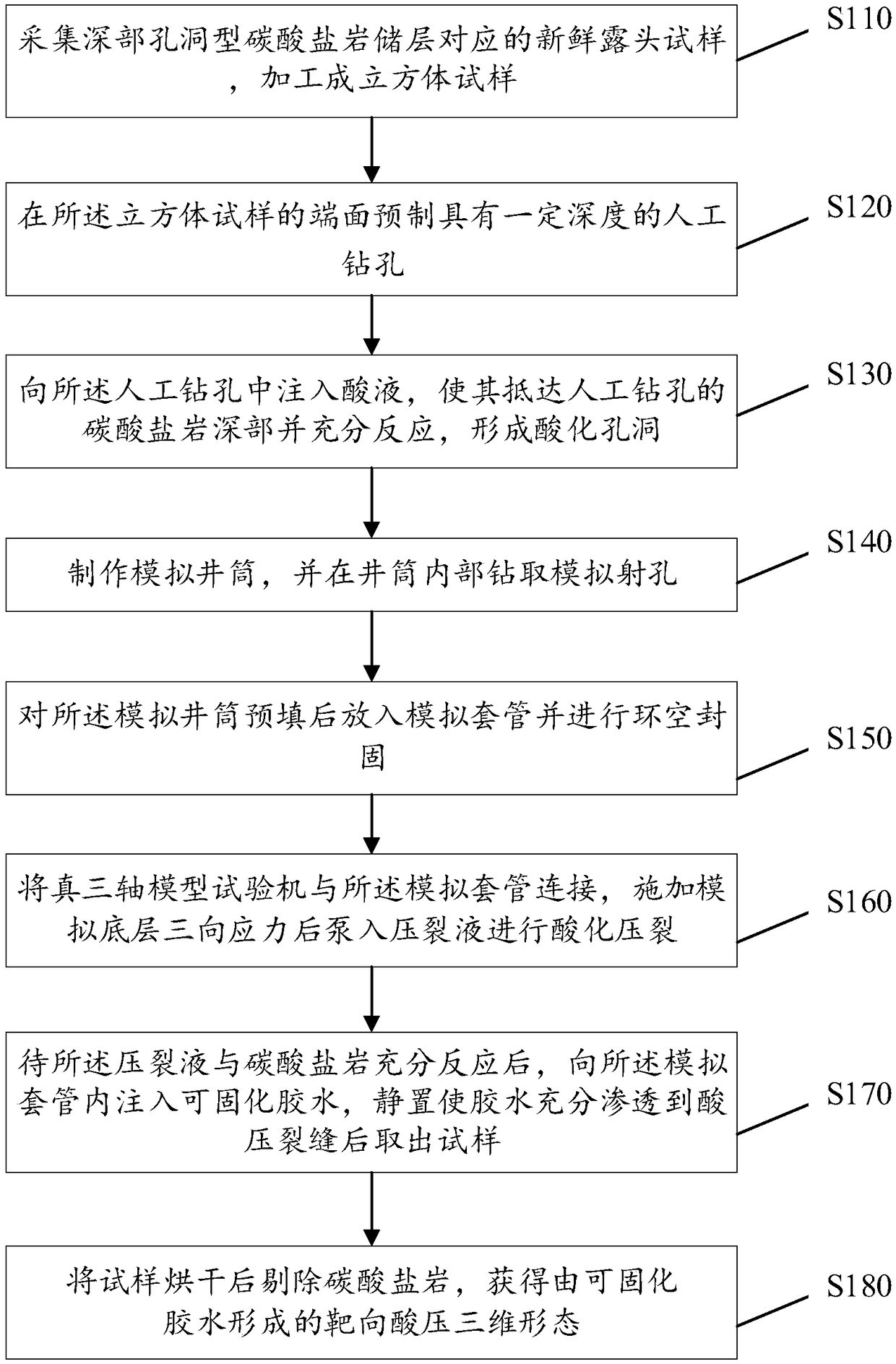

[0043] The embodiment of this application provides a physical simulation method for targeted acid fracturing of vug-type carbonate rocks, such as figure 1 shown, including the following steps:

[0044] Step S110: collecting fresh outcrop samples corresponding to deep vug carbonate reservoirs, and processing them into cube samples;

[0045] Specifically, the cube sample is processed to ensure that three sets of ground stress parameters in different directions can be effectively applied when true triaxial loading is performed.

[0046] Step S120: prefabricating artificially drilled holes with a certain depth on the end face of the cube sample;

[0047] Specifically, a professional rock cutting machine is used to manually drill holes on one end face of the cube sample, or two or more end faces. The depth of artificial drilling is 45-55mm, and the number of artificial drilling is one or more than one. The shape of the end face of the drill hole can be round, square, polygonal, ...

Embodiment 2

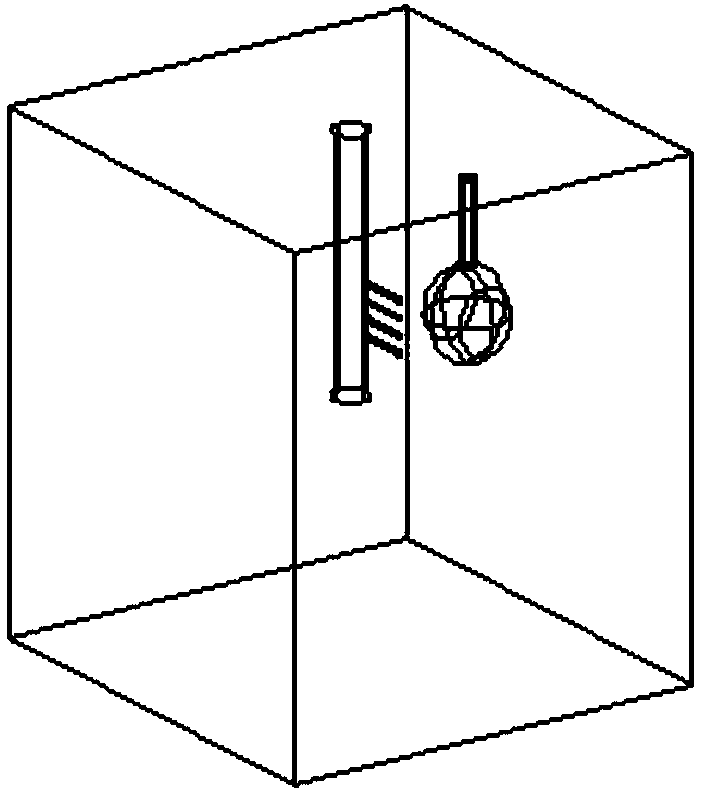

[0067] This embodiment applies the physical simulation method for targeted acid fracturing of vug-type carbonate rocks provided in Embodiment 1, specifically including:

[0068] S201: Collect fresh outcrop samples corresponding to vug-type carbonate reservoirs, use a large stone cutting machine with a cutter head diameter of 1m to process the samples into 300mm×300mm×300mm cube samples, and ensure the parallelism of each end surface and integrity;

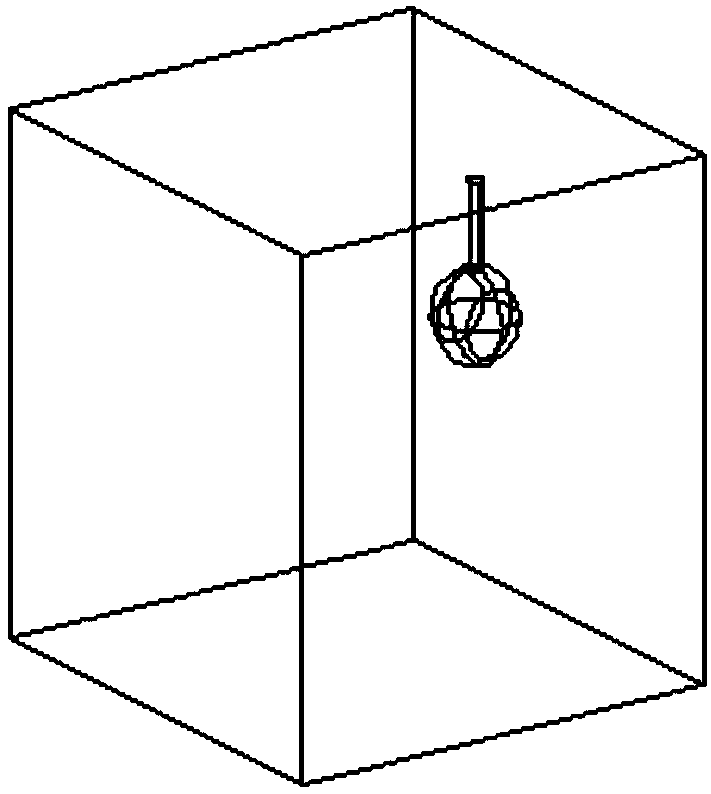

[0069] S202: if figure 2 As shown, a professional rock cutting machine is used to prefabricate an artificial cylindrical drill hole with a diameter of 5mm and a depth of 50mm on one end of the cube sample, and ensure the smoothness of the drill hole and the integrity of the sample;

[0070] S203: Use pre-configured hydrochloric acid with a volume concentration of 10%, inhale it through a disposable syringe, and slowly inject 50ml into the borehole at room temperature until it reaches the deep part of the artificially drilled carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com