Flour bran heat pump drying device

A heat pump drying and bran technology, which is applied in the direction of drying gas arrangement, drying solid materials, drying granular materials, etc., can solve the problems of difficult control of drying quality, unfavorable popularization and application, complicated equipment, etc., and achieves precise control of drying temperature and is easy to promote Application, the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

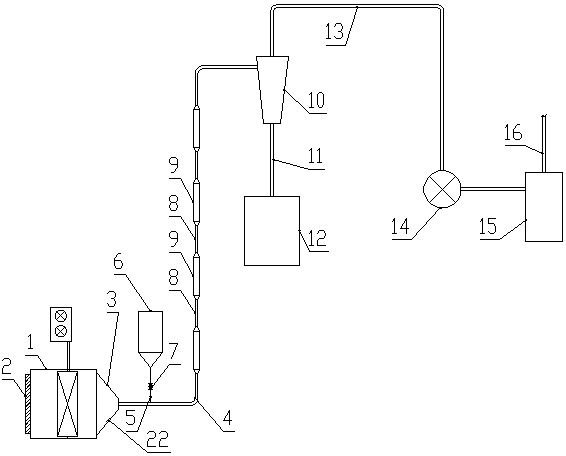

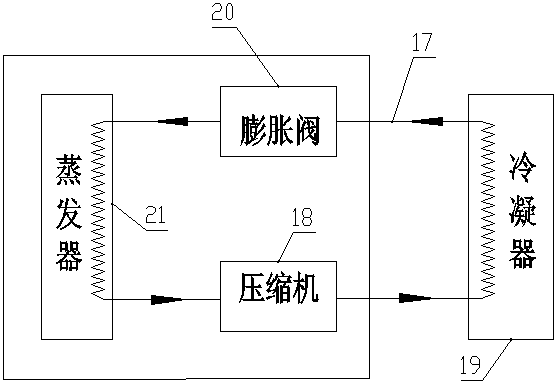

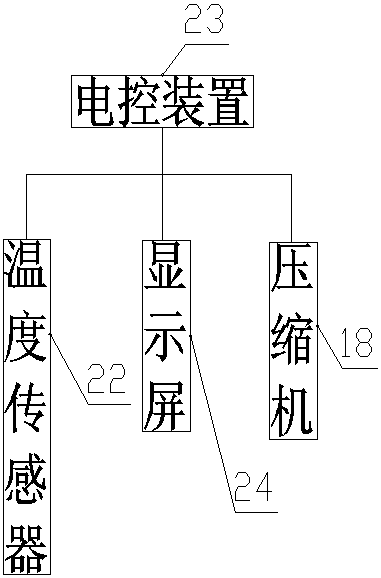

[0022] Such as Figure 1 to Figure 3 As shown, the flour bran heat pump drying device of the present invention comprises a heat pump system and a heating chamber 1; the air inlet of the heating chamber 1 is provided with an air filter 2, and the air outlet 3 of the heating chamber 1 is connected with an air supply pipe 4; For the downstream direction, the upstream end of the air supply pipe 4 is connected with a feed pipe 5, and the feed pipe 5 is upwardly connected with a raw powder storage tank 6 for storing the raw powder of flour bran, and the feed pipe 5 is provided with a feed valve 7;

[0023] The air supply pipe 4 in the downstream direction of the feed pipe 5 is connected in series with some speed-up pipe sections 8 and some deceleration pipe sections 9, the pipe diameter of the speed-up pipe sections 8 is smaller than the deceleration pipe sections 9, and the speed-up pipe sections 8 and the deceleration pipe sections 9 are arranged alternately; The speed increase p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com