A Nonlinear Torsional Mode Ultrasonic Guided Wave Method for Micro-Damage Evaluation of Metal Tubes

A technology of torsional mode and ultrasonic guided wave, which is applied to the analysis of solids by using sound waves/ultrasonic waves/infrasonic waves, material analysis by using sound waves/ultrasonic waves/infrasonic waves, and processing detection response signals. It can solve the limited number of fundamental frequency mode points , use restrictions and other issues, to achieve the effects of analysis and processing, noise reduction, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

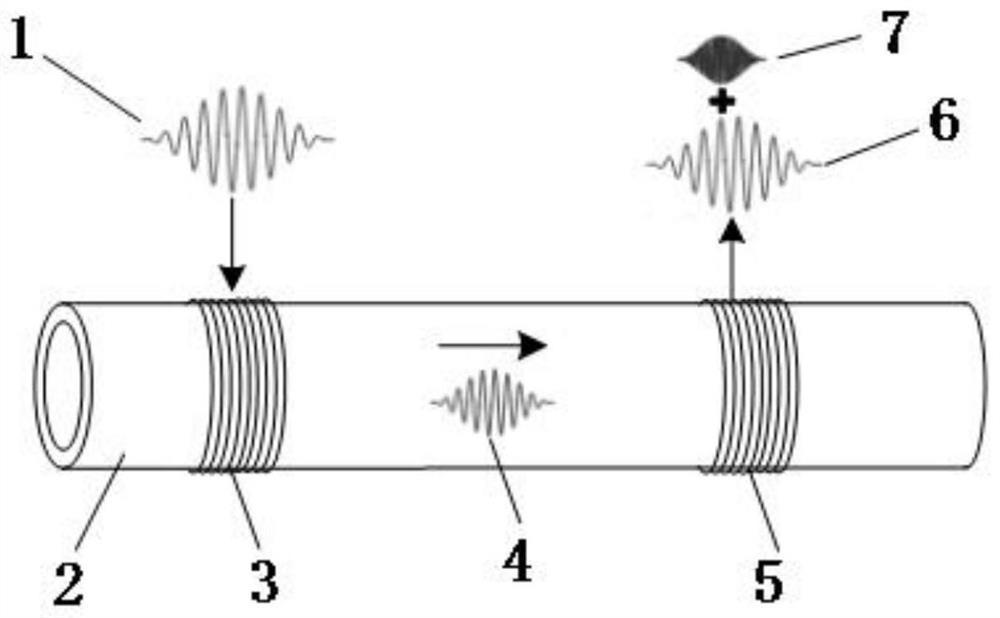

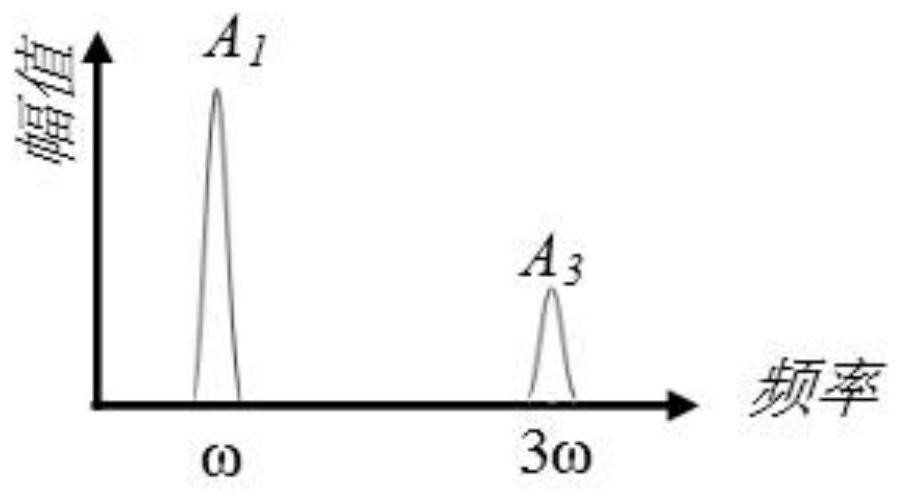

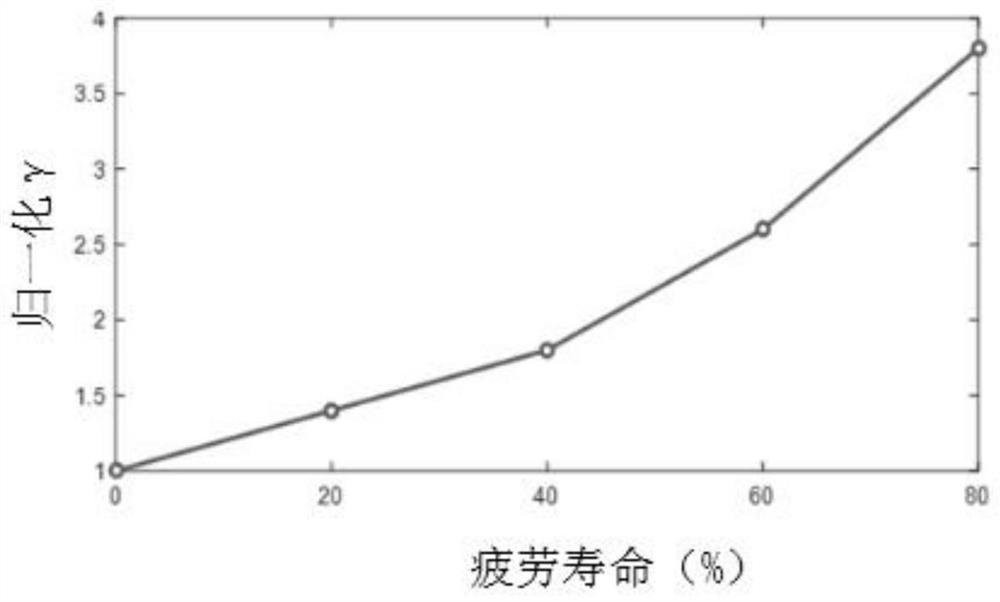

[0031] The non-linear torsional mode ultrasonic guided wave evaluation method of circular pipe micro-damage of the present invention excites an ultrasonic signal of a certain frequency through the excitation / receiving unit, reduces noise through the impedance, connects the excitation transducer, and sends it to the test piece through the coupling agent. , the other end of the test piece is connected to the receiving transducer to detect the propagated guided wave signal, filtered by the receiving preamplifier and sent to the oscilloscope, and the signal is averaged 200-2000 times in the oscilloscope to improve the signal-to-noise ratio. Store th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com