Regression analysis method of square steel pipe truss N type node bearing capacity for trestle

A technique of regression analysis and square steel pipes, applied in the direction of truss bridges, bridges, bridge forms, etc., to achieve the effects of perfect methods, accurate results, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

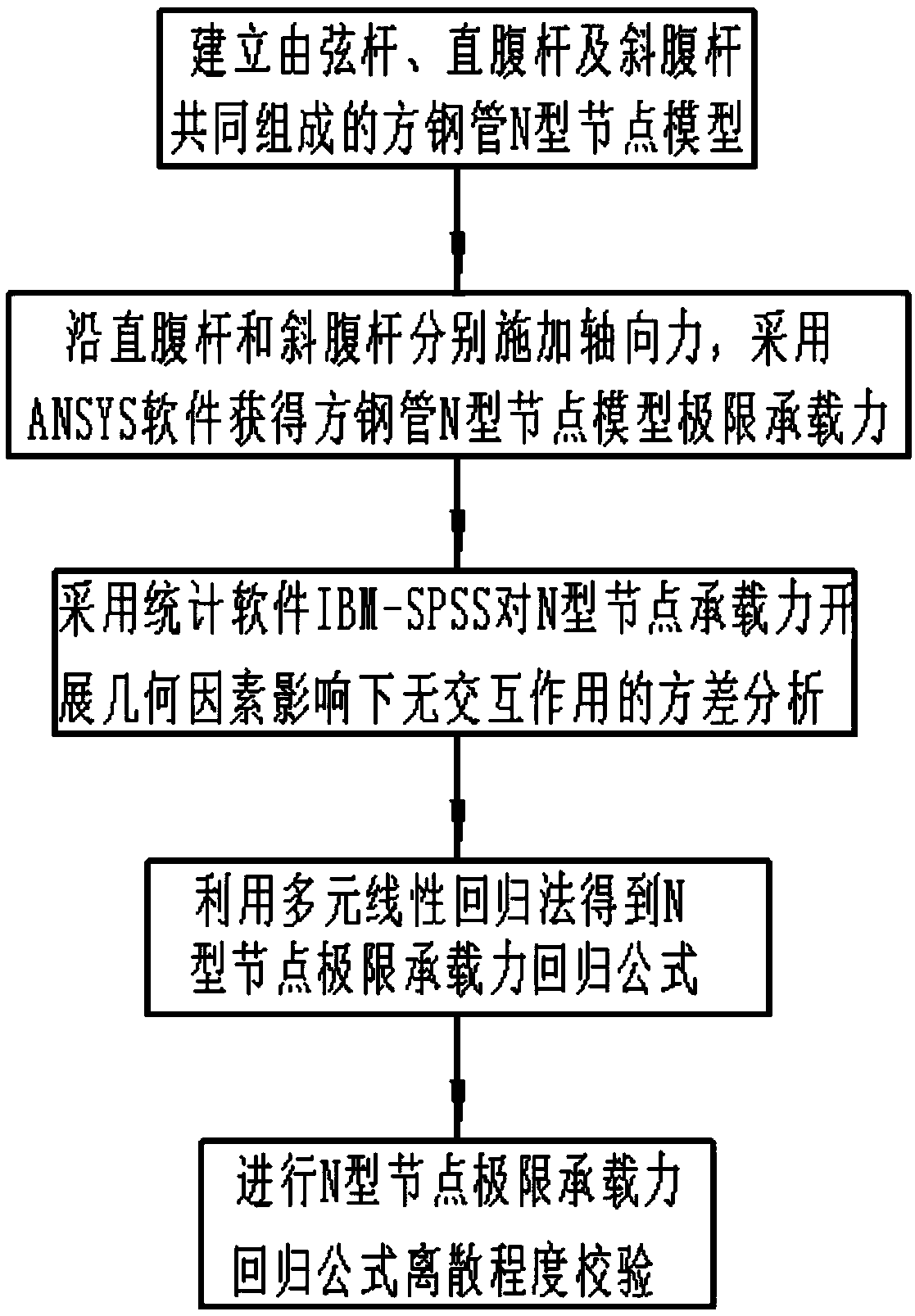

[0054] Such as figure 1 As shown, a method for regression analysis of the bearing capacity of square steel pipe truss N-type joints for trestle bridges mainly includes the following steps:

[0055] Step 1: Combining four sets of dimensionless geometric parameters: β, γ, τ and O v Orthogonal experiments were designed, and the solid element SOLID185 in the ANSYS software element library was used to establish an N-type node model of a square steel pipe composed of chords, straight webs and diagonal webs. The solid element SOLID185 was defined by 8 nodes, and each A node has three degrees of freedom for translation along the x, y, and z directions. The straight web bar is connected vertically to the chord bar, and the diagonal web bar is connected to the chord bar at an angle of 60°. The chord in the N-type node model of the square steel pipe The length of rods, straight webs and oblique webs is three times the pipe diameter, and the diameter of the chord is 200mm, where β is the r...

Embodiment 2

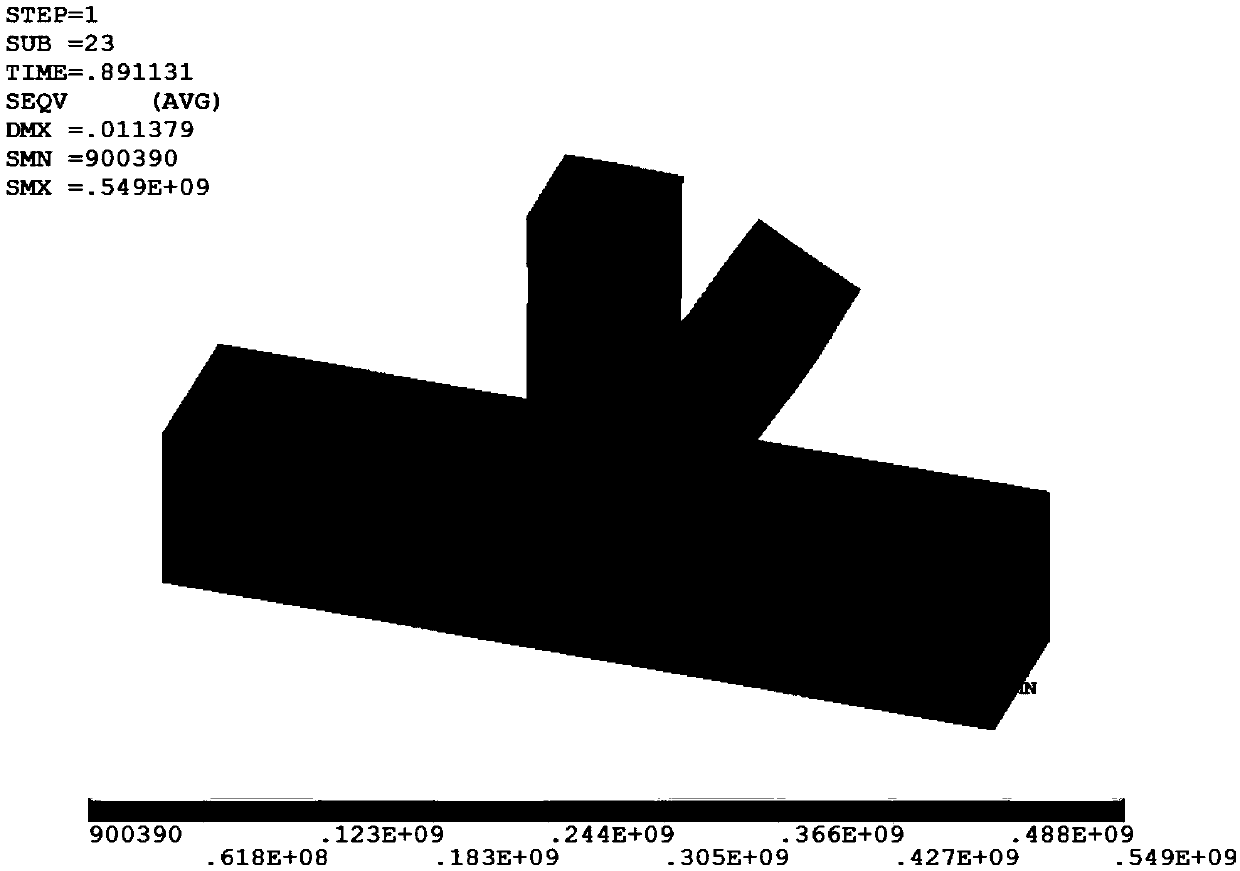

[0085] Taking model No. 18 as an example, the finite element model diagram is obtained by using the method of step 2 in embodiment 1:

[0086] Depend on figure 2 It can be seen that when the web bears an axial force of 962kN, the maximum stress in this area is 549MPa, and the full-section stress of the web reaches more than 305MPa, basically entering a plastic state, and the chord top plate is in a point-like yield state in the peripheral area of the web. When the load is reached, the load cannot continue to increase, and the node enters the failure state.

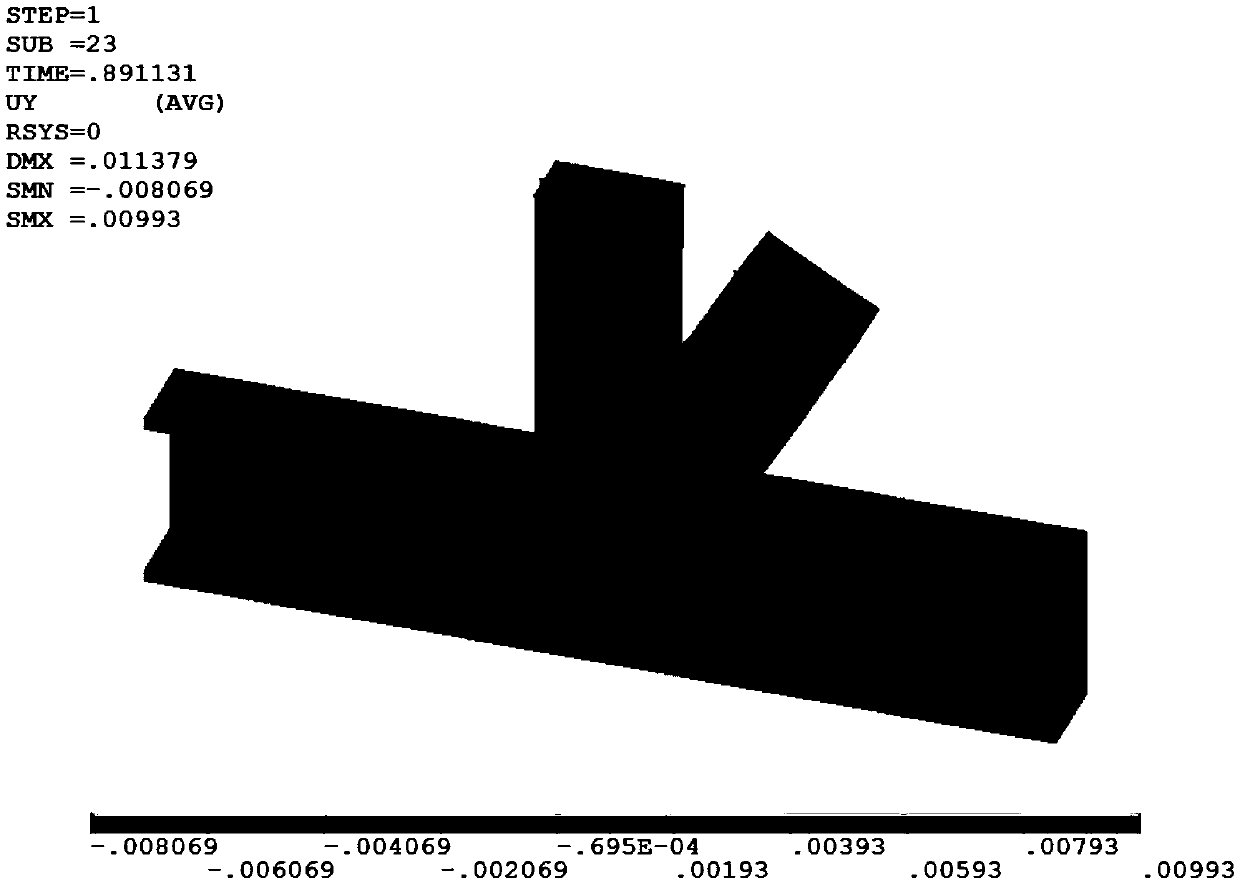

[0087] exist image 3 and Figure 4 In , the deformation effect is enlarged by 3 times, and the large displacement effect caused by the support at the end of each rod is ignored. When the straight web bar is loaded to 962kN, the center of the interface between the chord and the left side plate of the straight web bar shows a large positive deformation protruding from the surface of the chord, and the Uy displacement ...

Embodiment 3

[0090] Utilize the method of embodiment 1, measure the impact of β change on the ultimate bearing capacity of model nodes:

[0091] Keeping γ and τ constant, and β gradually increasing, the change trend of the ultimate bearing capacity of the model nodes is shown in Table 2:

[0092] Table 2 Ultimate bearing capacity of nodes under the influence of β

[0093]

[0094]

[0095] Conclusion: On the premise of keeping γ and τ constant, when β gradually increases, the ultimate bearing capacity of the model all shows an upward trend, O v The change of β basically has no effect on the change trend of bearing capacity with β value. It shows that as the diameter of the web increases, the overall stiffness of the joint increases, and the bearing capacity of the joint increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com