Automobile manufacturing intelligent production scheduling processing method

A processing method and automobile manufacturing technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problem of inaccurate matching between parts preparation and demand, and achieve the goal of shortening the planning and allocation time, shortening the engineering cycle, and improving the arrangement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

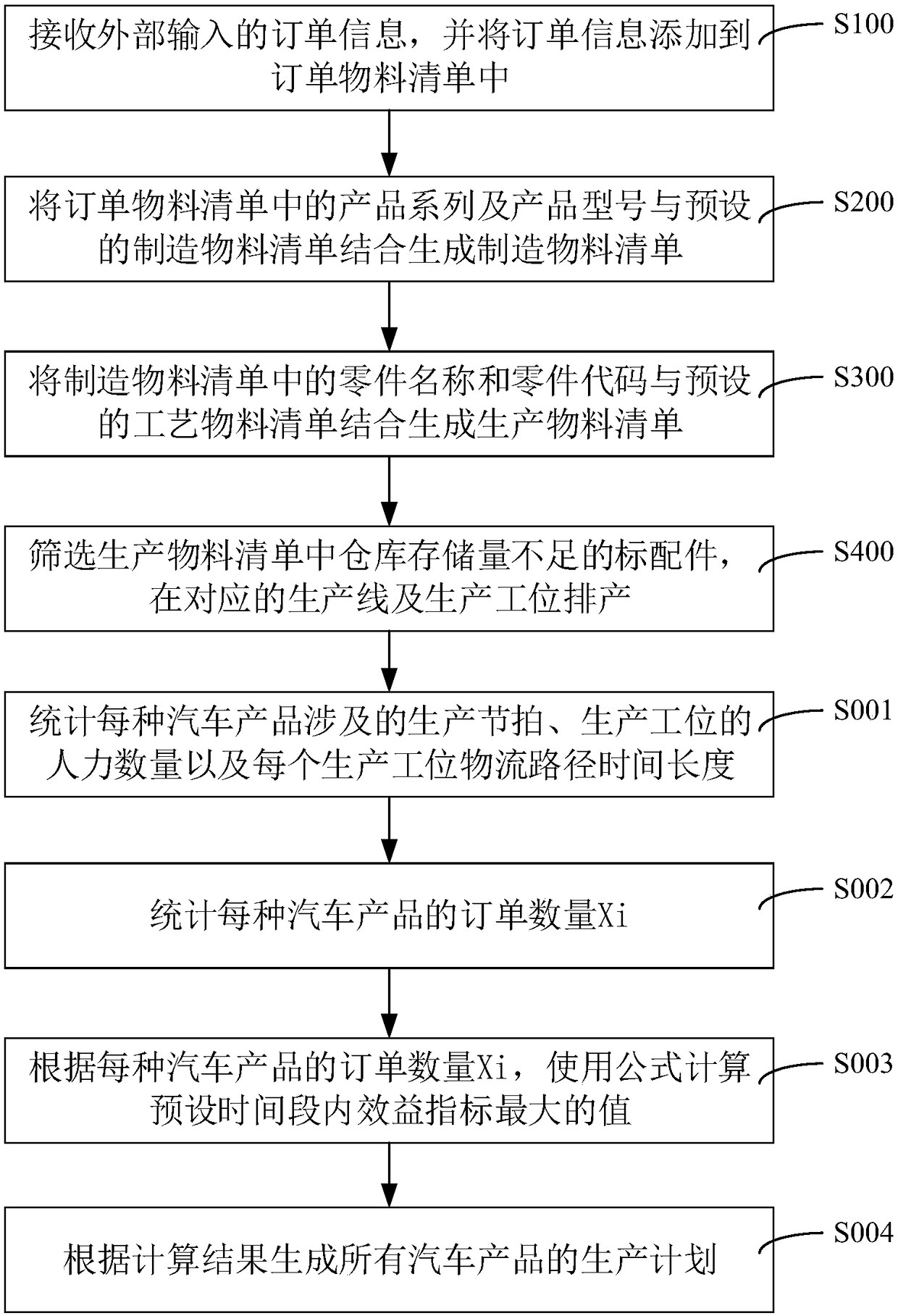

Method used

Image

Examples

Embodiment Construction

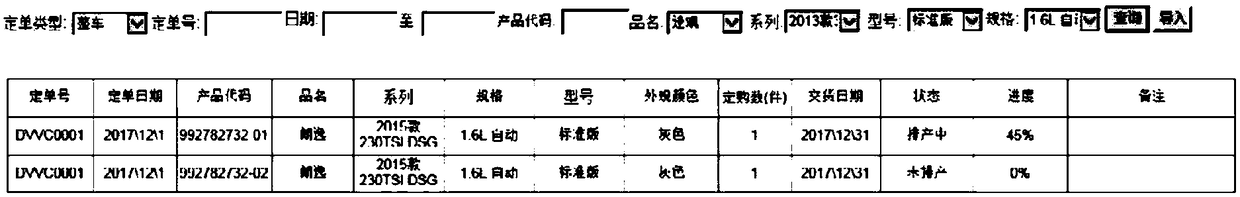

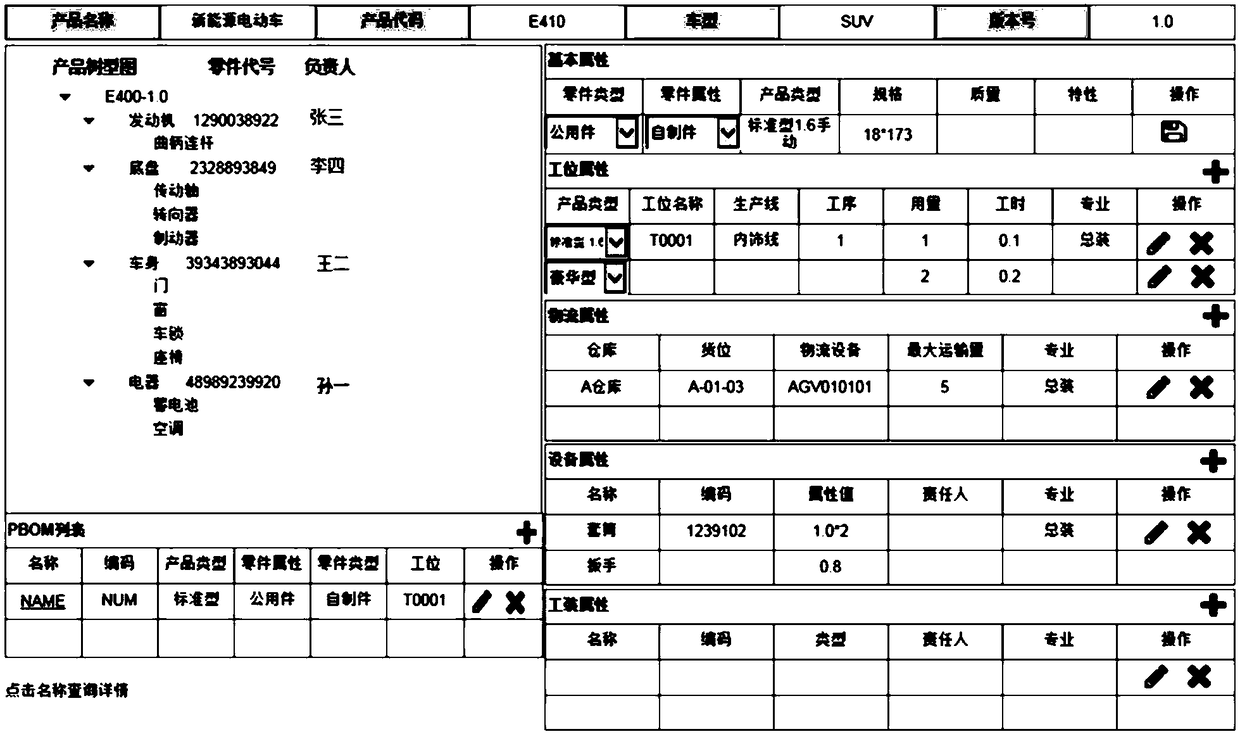

[0046] In order to make the object, technical solution and advantages of the present invention more clear, the specific implementation manner of the intelligent production scheduling processing method for automobile manufacturing of the present invention will be described below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0047] First of all, it needs to be explained that the method of the present invention is realized through software execution. Software programming adopts a systematic way of thinking, proceeds from a global perspective, and takes customers as the center. It examines and thinks about the existing models, grasps the needs of customers, grasps the diversity and complexity of products in a timely manner, and eliminates or connects informatization Isolated islands to achieve global data integration. That is to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com