High-cooling enameled copper flat wire with good flexibility

A technology with high heat dissipation and flexibility, applied in the direction of flat/ribbon cables, conductive core components, conductors, etc., it can solve the problems of poor flexibility of enameled copper flat wires, difficult to go to international occasions, short circuit between coil turns, etc. To achieve the effect of good heat dissipation performance, improved service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

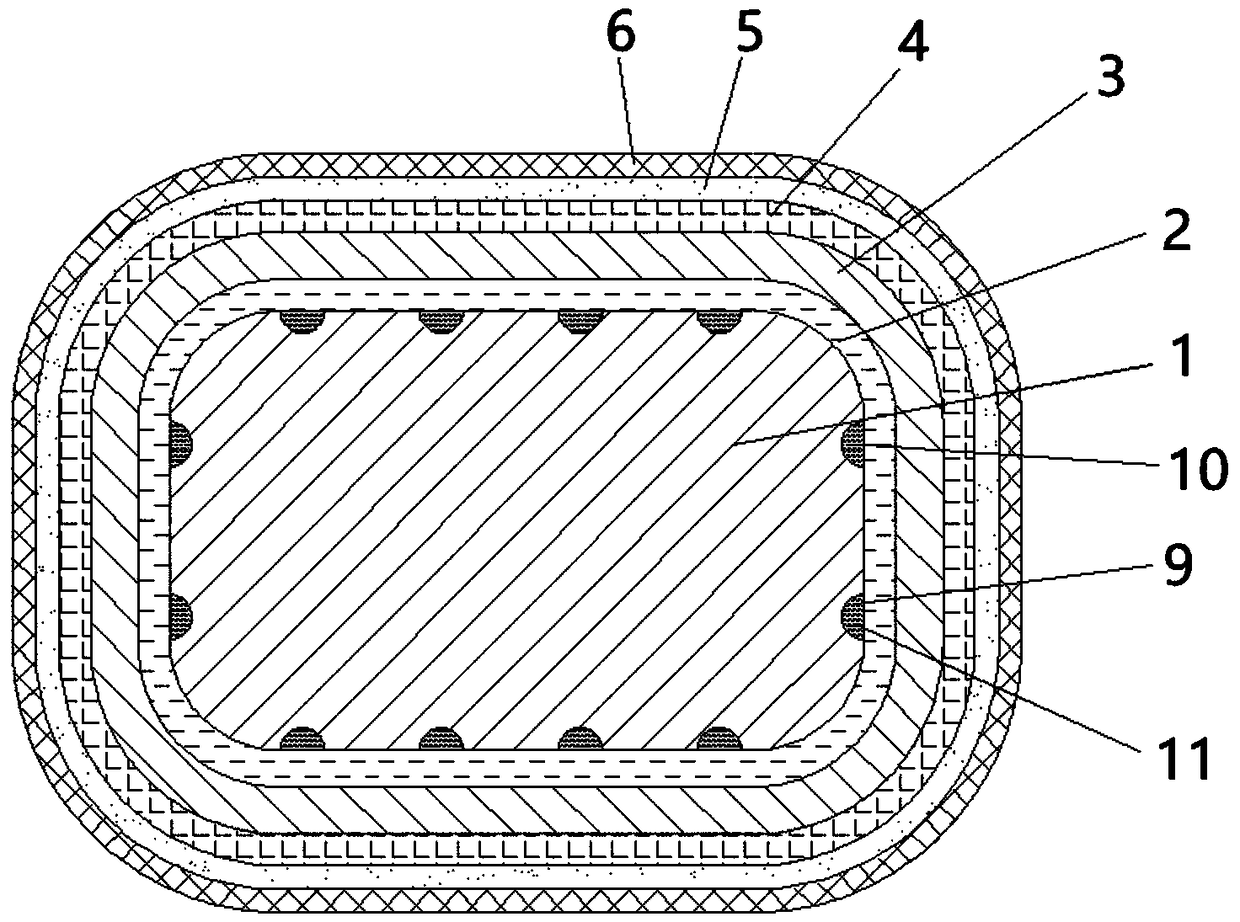

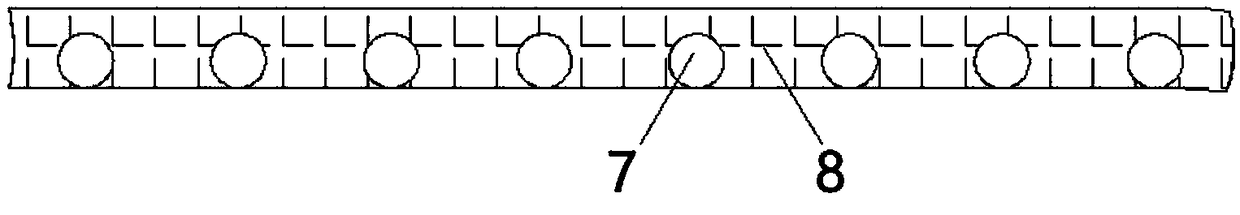

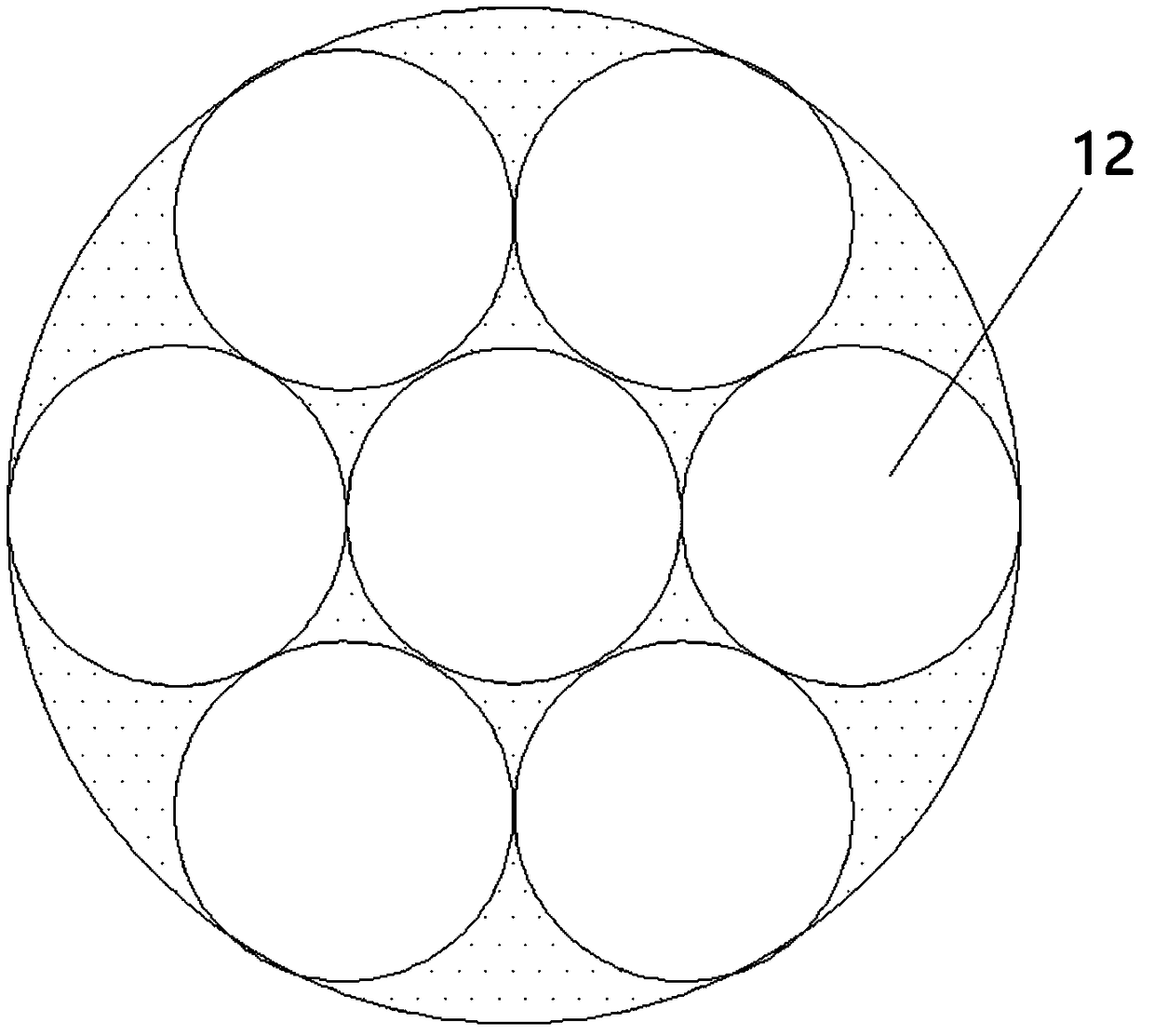

[0017] Embodiment: a kind of high heat dissipation enamelled copper flat wire with good flexibility has a structure such as Figure 1 to Figure 3 As shown, it includes a copper flat wire core 1, and the outer side of the copper flat wire core 1 is provided with a magnetic particle coating 2, a first aromatic polyimide paint layer 3, a tear-resistant layer 4, a second aromatic polyimide An imide paint layer 5 and a waterproof layer 6; the tear-resistant layer 4 includes a plurality of equally spaced Kevlar fiber bundles 7, the outer surface of the Kevlar fiber bundles 7 and the adjacent Kevlar fiber bundles 7 The gaps between them are all coated with polyamideimide insulating varnish 8; the outer surface of the copper flat core 1 is provided with semi-cylindrical grooves 9 distributed at equal intervals, and the semi-cylindrical grooves 9 and the magnetic particle coating An insulating film 10 is provided between the layers 2; the Kevlar fiber bundle 7 is a mesh structure forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap