Multi-layer ceramic capacitor and fabrication method thereof

A technology of multilayer ceramics and capacitors, which is applied in the manufacture of capacitors, laminated capacitors, capacitors, etc., can solve the problems of ceramic body density and uniformity decline, adhesive removal is not thorough, etc., to achieve good consistency, high density and good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

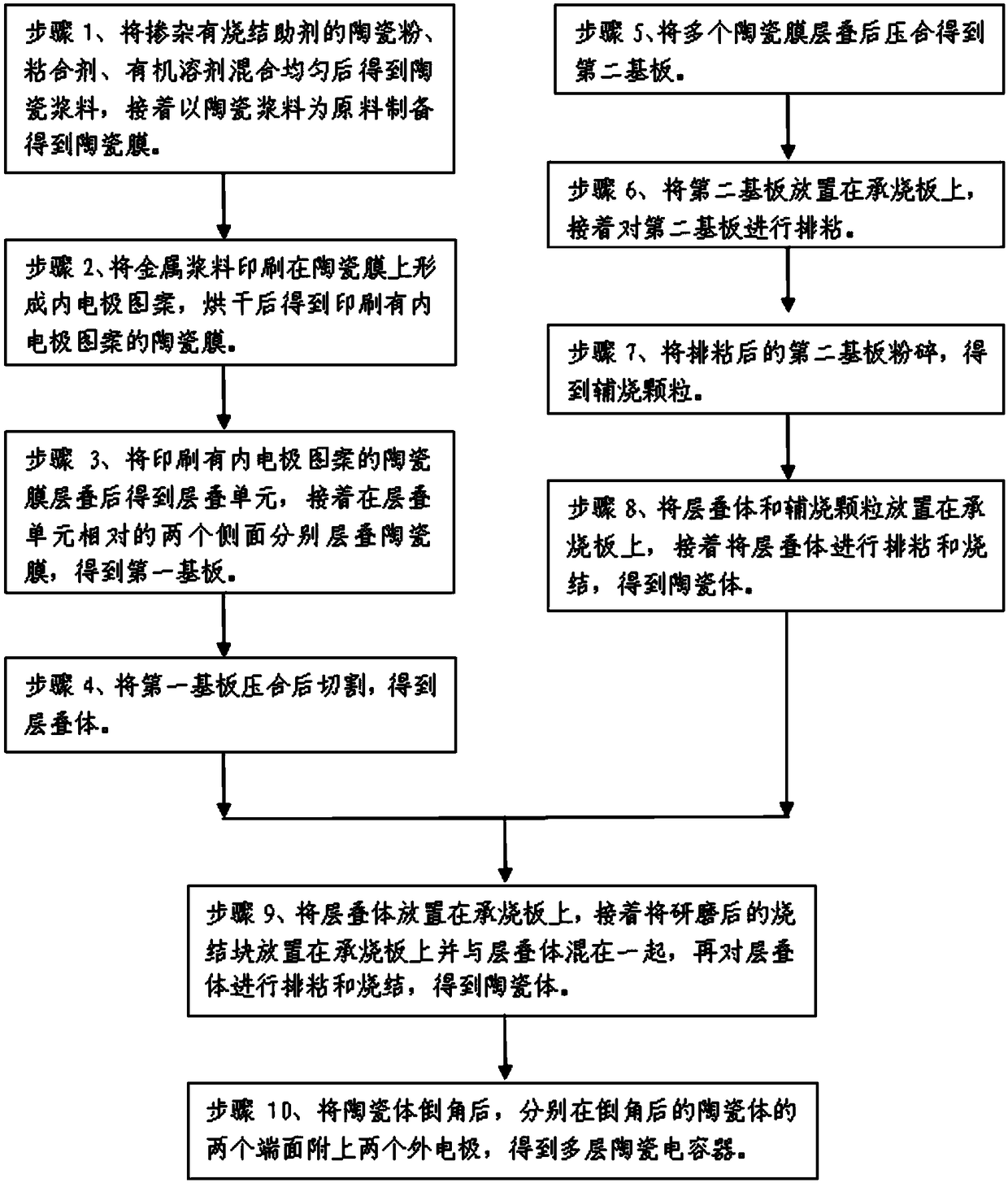

[0048] An embodiment of the multilayer ceramic capacitor of the present invention, combined with figure 1 , the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0049] Step 1: Mix ceramic powder doped with sintering aid, binder, and organic solvent uniformly to obtain a ceramic slurry, and then use the ceramic slurry as a raw material to prepare a ceramic film.

[0050] In this embodiment, the operation of uniformly mixing the ceramic powder doped with sintering aid, the binder, and the organic solvent is as follows: the ceramic powder doped with the sintering aid, the adhesive, and the organic solvent are uniformly mixed by ball milling , The ball milling time can be 10~16h.

[0051] In the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com