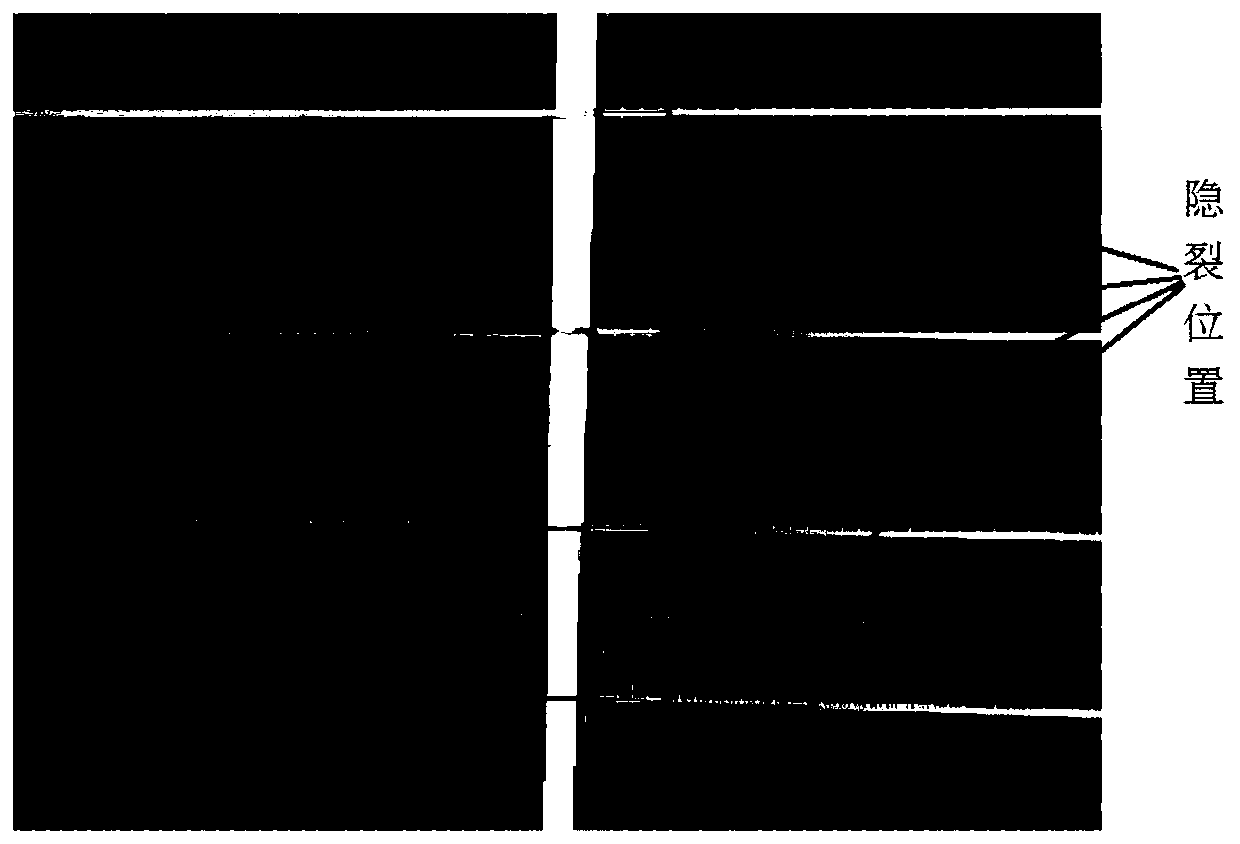

A Method for Improving Welding Hidden Cracks of Single Crystal Cells

A cell welding and cell technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as cracks that are prone to occur, and achieve the effect of avoiding debris or cracks and solving debris.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0028] A method for improving single-crystal cell welding cracks, comprising the following steps:

[0029] Step 1. Select two monocrystalline cells 3, face up, and align the end of the first monocrystalline cell with the head of the second monocrystalline cell, as shown in figure 1 shown;

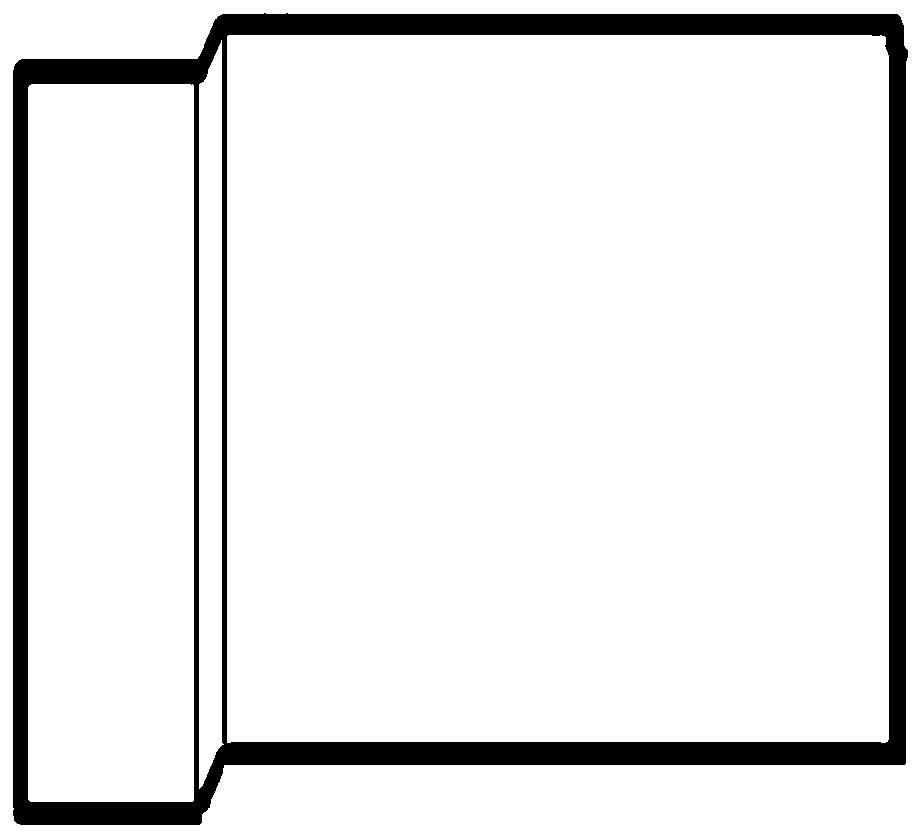

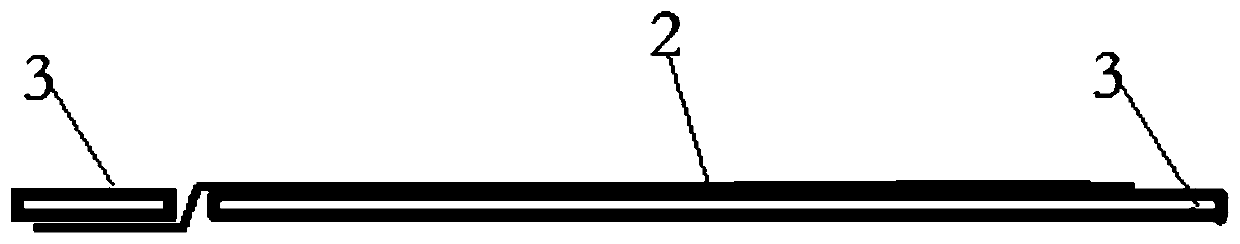

[0030] Step 2. Prepare an arched bent plate 1, such as Figure 4 As shown, the welding strip 2 is attached to the arched bending plate 1, so that the bending shape of the welding strip 2 is the same as that of the arched bending plate 1;

[0031] In the embodiment of the present invention, the material of the welding strip 2 is copper, and the surface is sprayed with a tin layer;

[0032] Such as Figure 5 As shown, step 3. Attach the above-mentioned bent ribbon 2 to the welding position of the two monocrystalline solar cells, so that the arched bending position of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com