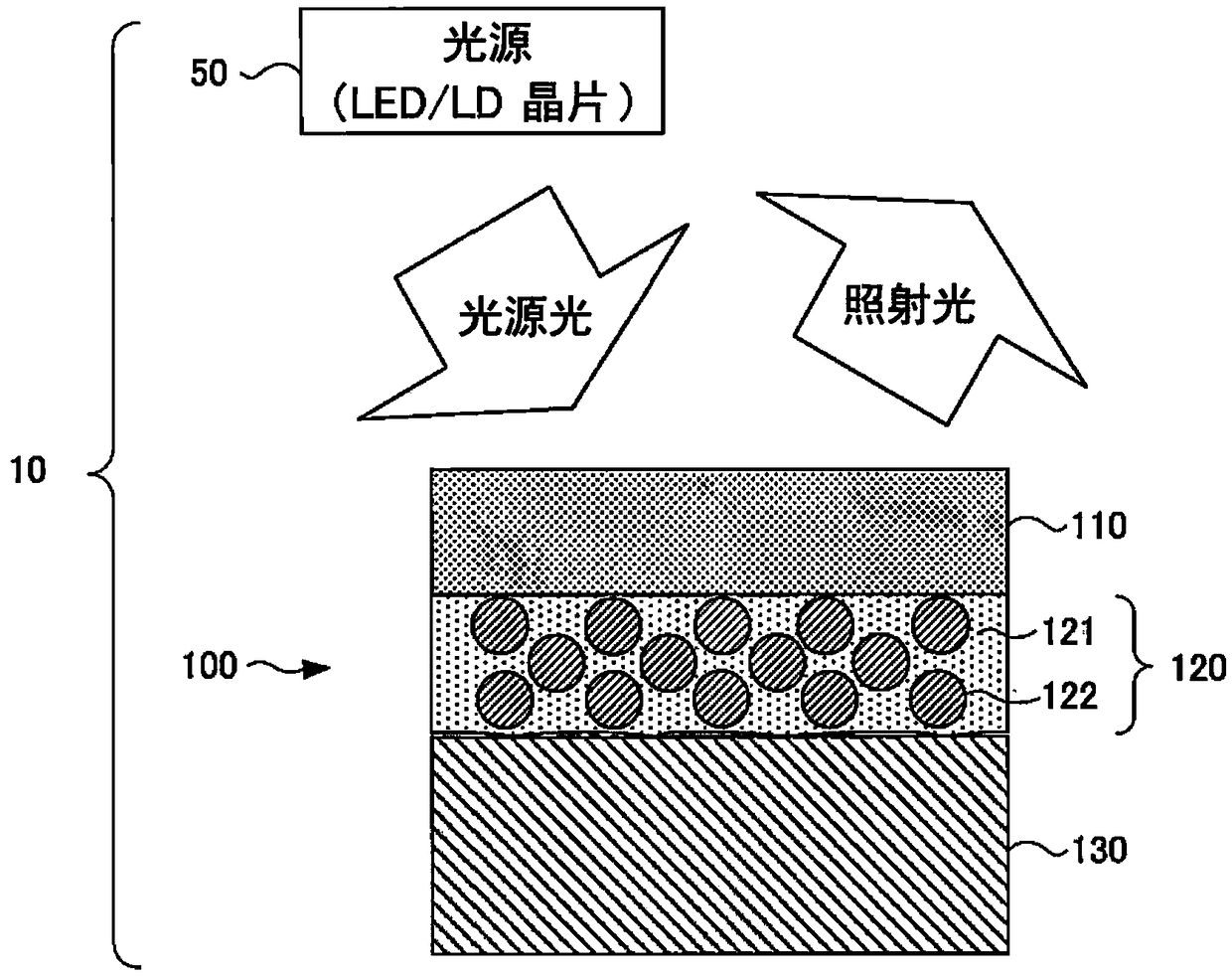

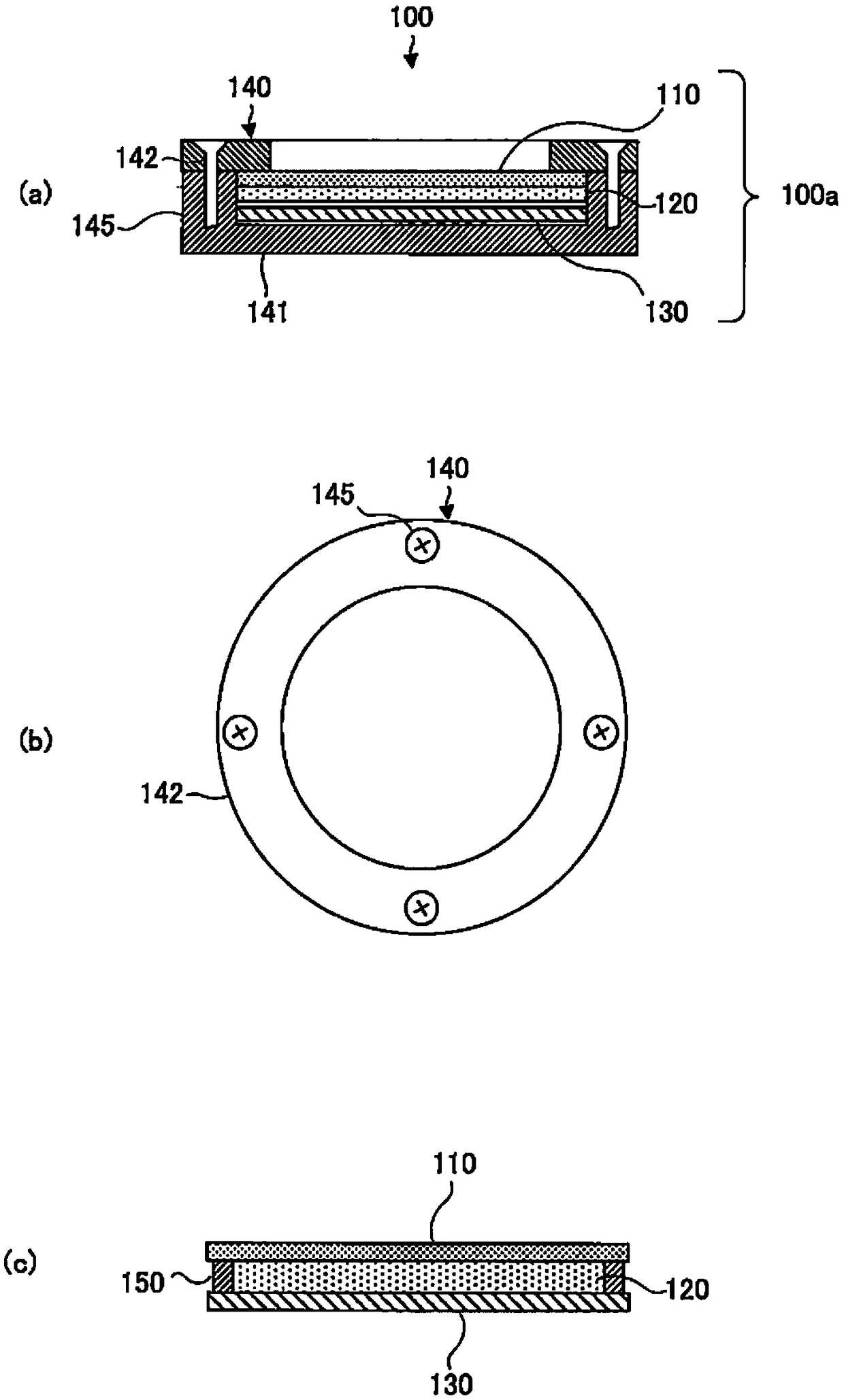

Wavelength conversion member, manufacturing method therefor, and light-emitting device

A technology of wavelength conversion and manufacturing method, which is applied in the direction of luminescent materials, lighting devices, luminescent coatings, etc., can solve the problem of not clearly describing the detailed structure of the abutment part of the fluorescent layer and the radiator abutment method, and achieve the suppression of thermal quenching, The effect of efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] (1. Evaluation of joining state)

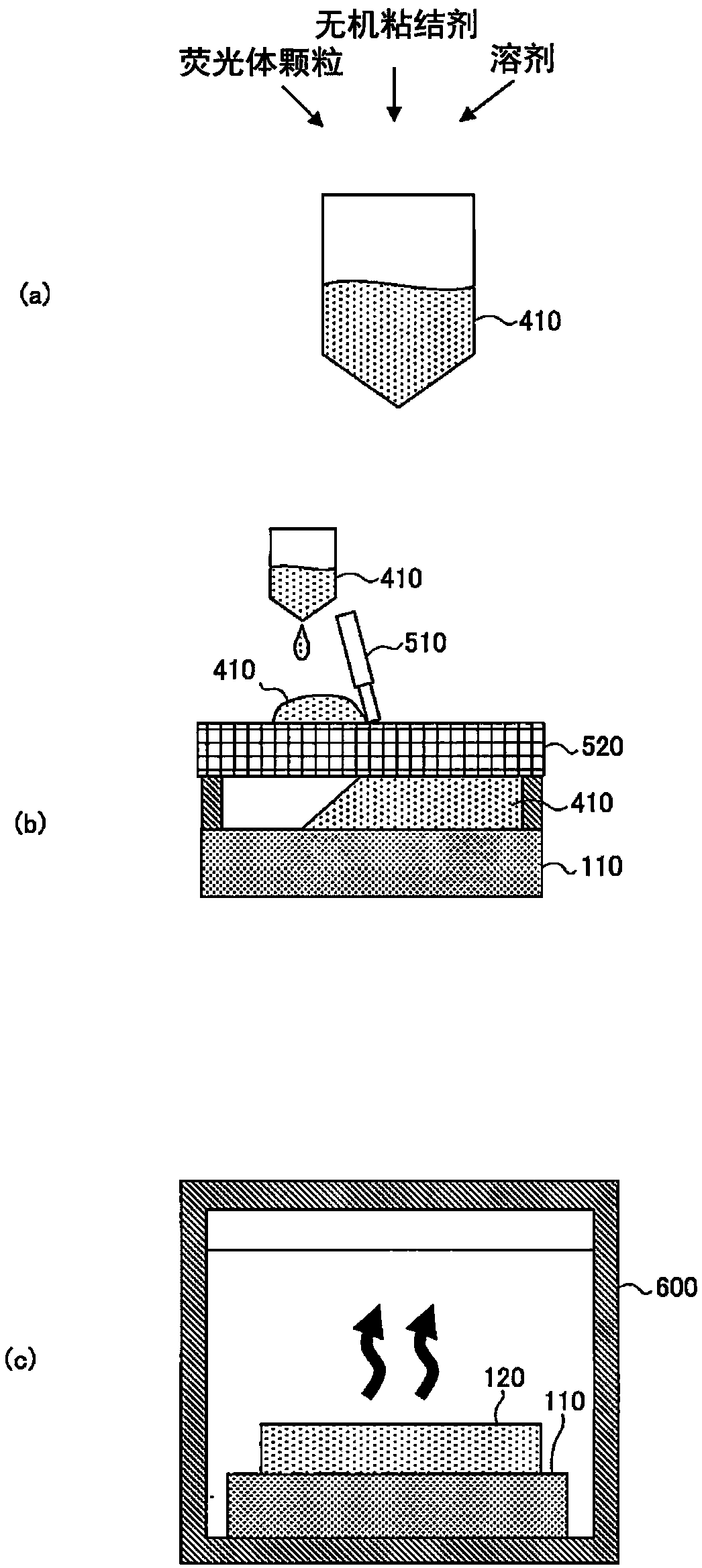

[0074] (1-1) Preparation method of the sample

[0075] The wavelength conversion members of Example 1, Comparative Examples 1 and 2 were fabricated. First, ethyl silicate, terpineol, and YAG phosphor particles (average particle diameter: 18 μm) were mixed to prepare a paste.

[0076] The prepared paste was applied on a sapphire plate serving as a transmissive material to a thickness of 40 μm using a screen printing method, followed by heat treatment to obtain an intermediate member. SEM observation was performed on a cross section perpendicular to the reflecting surface of the obtained intermediate member. Figure 4 (a) is a SEM photograph showing a partial cross section of a wavelength conversion member (cross section of an intermediate member). in addition, Figure 4 (b) is Figure 4 Si element mapping image of a partial cross-section of the wavelength conversion member shown in the SEM photograph of (a). It was confirmed that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com