Optical waveguide laminated body and manufacturing method therefor

A manufacturing method, optical waveguide technology, applied in the direction of optical waveguide light guide, optical waveguide coupling, light guide, etc., to achieve the effect of excellent insulation and heat resistance, excellent processing accuracy, and efficient removal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 9、 comparative example 1~ comparative example 4

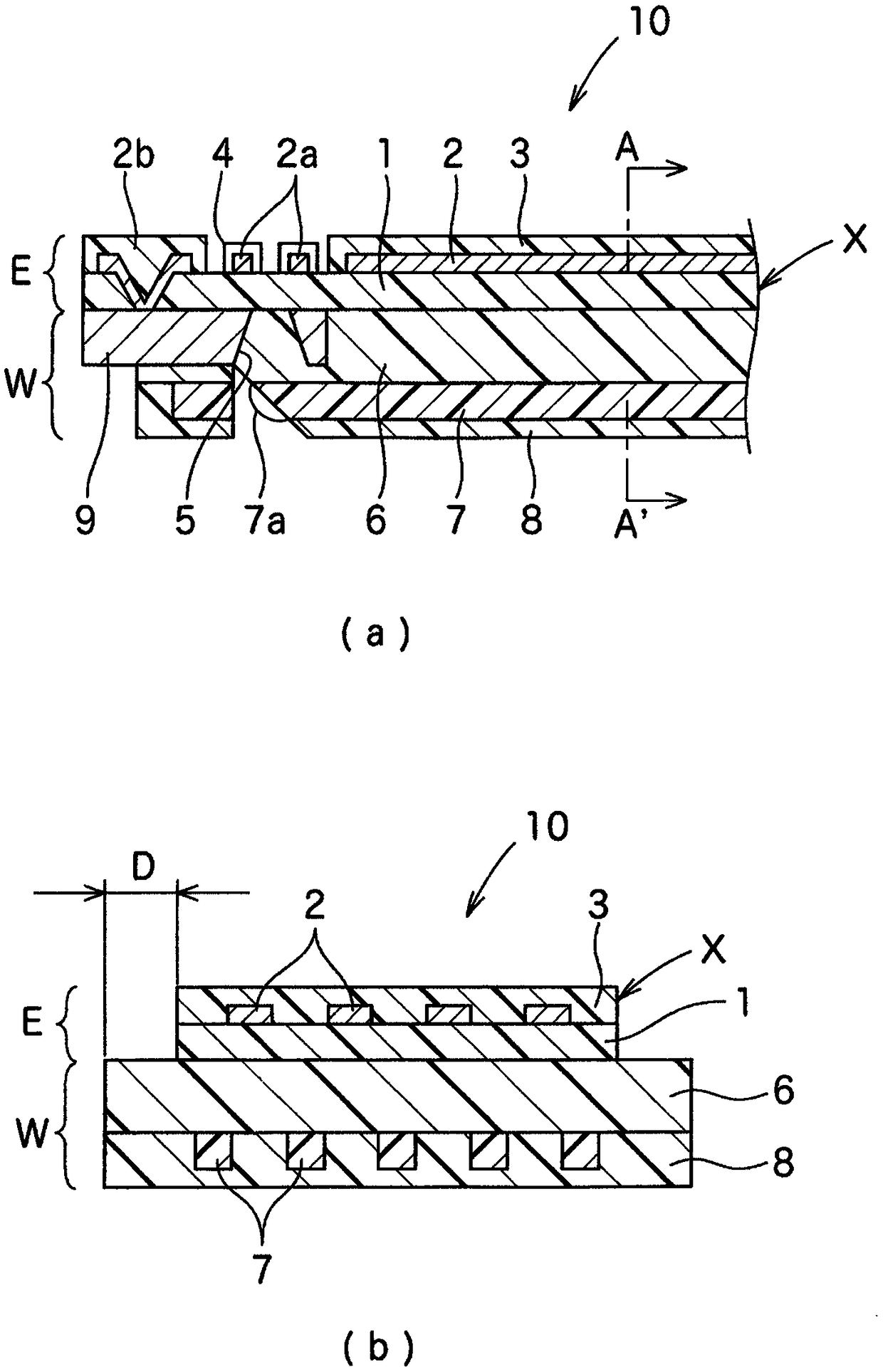

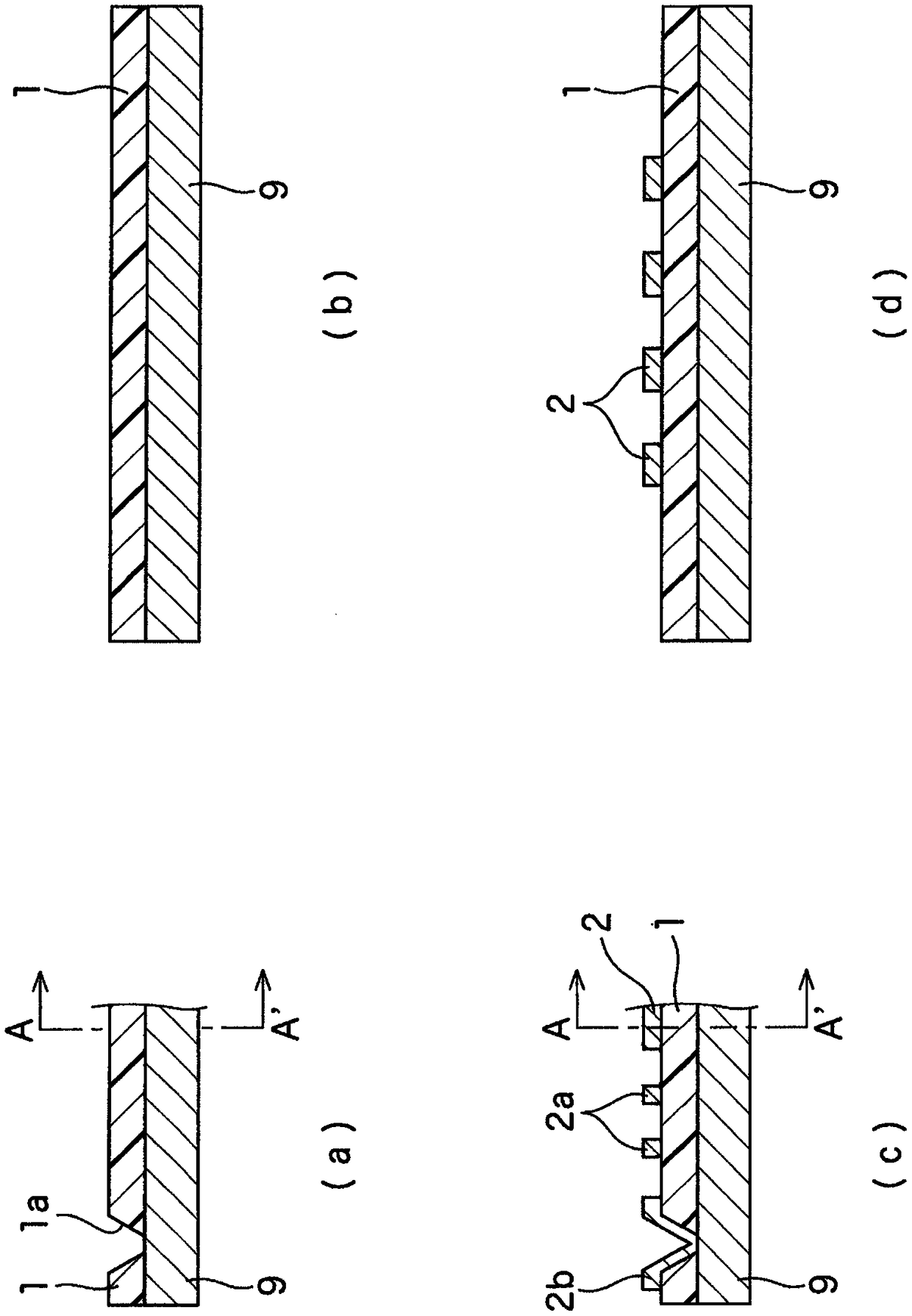

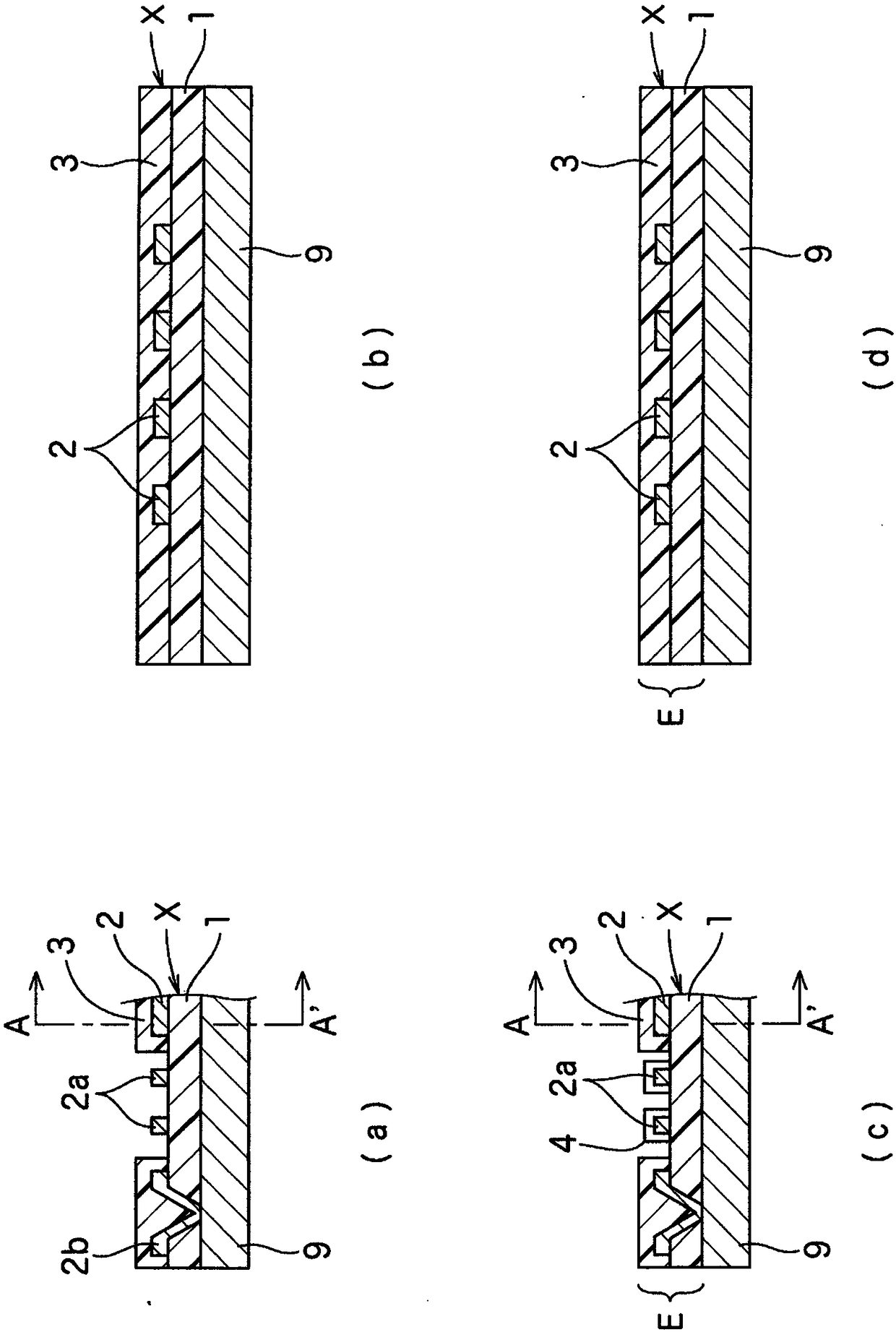

[0086] Using the material used for the optical waveguide W and the material used for the organic substrate layer X described later, the optical waveguide W (overall thickness 110 μm: Clad1 thickness 40 μm + Clad2 thickness 30 μm + Core thickness 40 μm ) by laminating an organic substrate layer X (total thickness 15 μm: thickness of insulating layer 10 μm + thickness of cover layer 5 μm), thereby producing samples simulating 13 kinds of optical circuit boards (Example 1 to Example 9, Comparative Example 1 -Comparative example 4), the combination of the material of the optical waveguide W and the material of the organic base material layer X at the laser processed part of these samples is shown in Table 1 described later. Then, these samples were irradiated with laser light in the thickness direction of the sample using four types of laser devices described later to remove the organic base material layer X only at one edge portion (region with a width of 50 μm) of the sample. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com