Vertical-axis wind turbine

A wind turbine, vertical axis technology, applied to wind turbines, wind turbines at right angles to the wind direction, engines, etc., can solve the problem of poor sand or rain erosion resistance, unstable operation of generator blades, and increased bearing usage. Time and other issues to achieve good heat transfer and thermal insulation properties, improve adhesion properties, poor heat resistance properties, and enhance service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

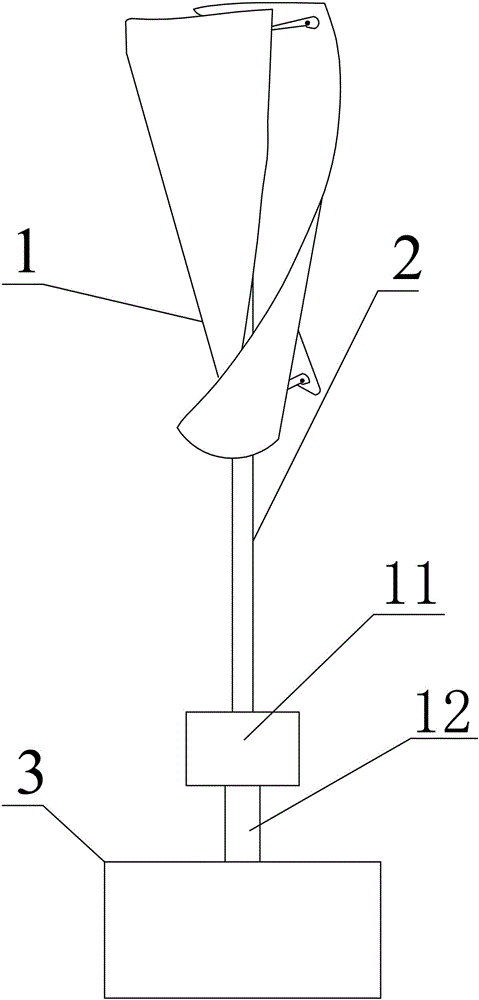

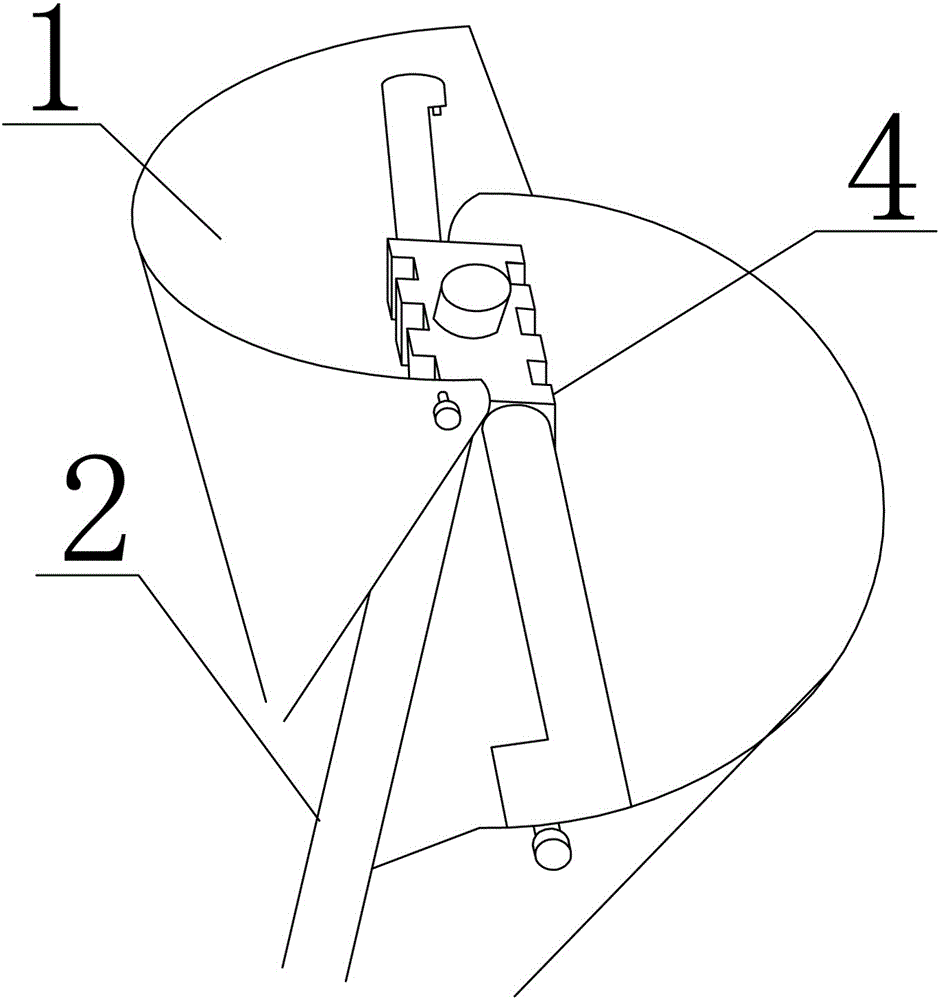

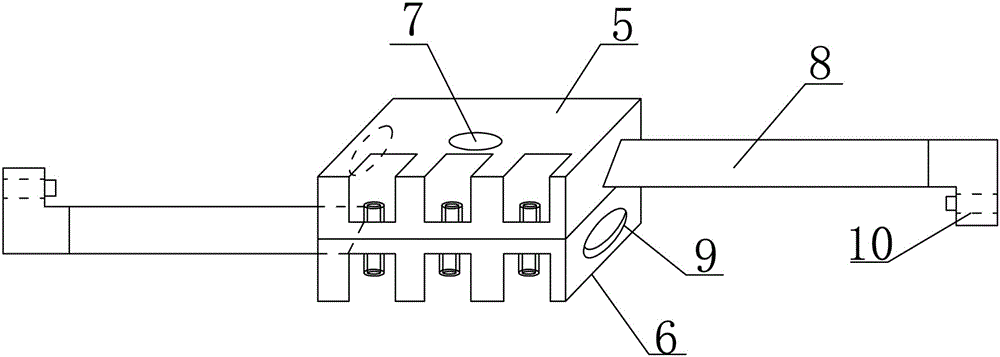

[0033] Such as Figure 1-Figure 3As shown, a vertical axis wind power generator includes a blade 1, a main shaft 2 and a main motor base 3, wherein the blade 1 is fixed on the main shaft 2 through a connecting bracket 4, and the connecting bracket 4 includes a vertically fixedly connected first connecting body 5 and The second connecting body 6, the first connecting body 5 and the second connecting body 6 are provided with interconnected spindle holes 7, the right side of the first connecting body 5 and the left side of the second connecting body 6 are respectively provided with connecting rods 8, the first The left side of the connecting body 5 and the right side of the second connecting body 6 are respectively provided with a threaded hole 9, and the top of the connecting rod 8 is provided with a threaded hole 10, and the two ends of the blade 1 are respectively connected to the threaded hole 9 and the threaded hole on the connecting bracket 4 by bolts. Two 10 are fixedly co...

Embodiment 2

[0044] The structure of the vertical axis wind power generator in embodiment 2 is the same as that of embodiment 1, the difference is that: the blade protective coating comprises the raw material preparation of the following parts by weight: 42 parts of styrene-acrylic emulsion, 28 parts of epoxy resin, modified nano TiO 2 11 parts, 9 parts of rutile titanium dioxide, 0.6 parts of dispersant, 0.9 parts of leveling agent, 9 parts of hollow glass microspheres, 0.2 parts of ultraviolet absorber, 6 parts of graphite powder, and 11 parts of organic solvent.

[0045] Wherein the dispersant is calcium stearate.

[0046] Among them, the leveling agent is an acrylic leveling agent.

[0047] Wherein the organic solvent is butyl acetate.

[0048] Wherein the ultraviolet absorber is 2-hydroxy-4-methoxybenzophenone.

[0049] Among them, modified nano-TiO 2 The preparation method is: TiO 2 Dispersed in an aqueous solution of γ-aminopropyltriethoxysilane with a mass fraction of 2%, in w...

Embodiment 3

[0053] The structure of the vertical axis wind power generator in embodiment 3 is the same as that of embodiment 1, the difference is that: the blade protective coating comprises the raw material preparation of following parts by weight: 44 parts of styrene-acrylic emulsion, 26 parts of epoxy resin, modified nano TiO 2 10 parts, 10 parts of rutile titanium dioxide, 0.7 parts of dispersant, 0.8 parts of leveling agent, 10 parts of hollow glass microspheres, 0.3 parts of ultraviolet absorber, 5 parts of graphite powder, and 12 parts of organic solvent.

[0054] Wherein the dispersant is monoglyceride stearate.

[0055] Among them, the leveling agent is an acrylic leveling agent.

[0056] Wherein the organic solvent is methyl nylon acid.

[0057] Wherein the ultraviolet absorber is phenyl salicylate.

[0058] Among them, modified nano-TiO 2 The preparation method is: TiO 2 Dispersed in an aqueous solution of γ-aminopropyltriethoxysilane with a mass fraction of 3%, in which T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com