A high-gravity-continuous micro-impingement flow reactor based on the Bagua diagram principle

An impinging flow reactor, hypergravity technology, applied in chemical/physical/physical-chemical nozzle reactors, chemical instruments and methods, chemical/physical processes, etc. Concentration fluctuates greatly, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] In order to facilitate the understanding of the present invention, the specific structure that can realize an embodiment of the present invention will be described in detail below first. It should be understood that there are various structural forms in the specific realization of the present invention. Example description.

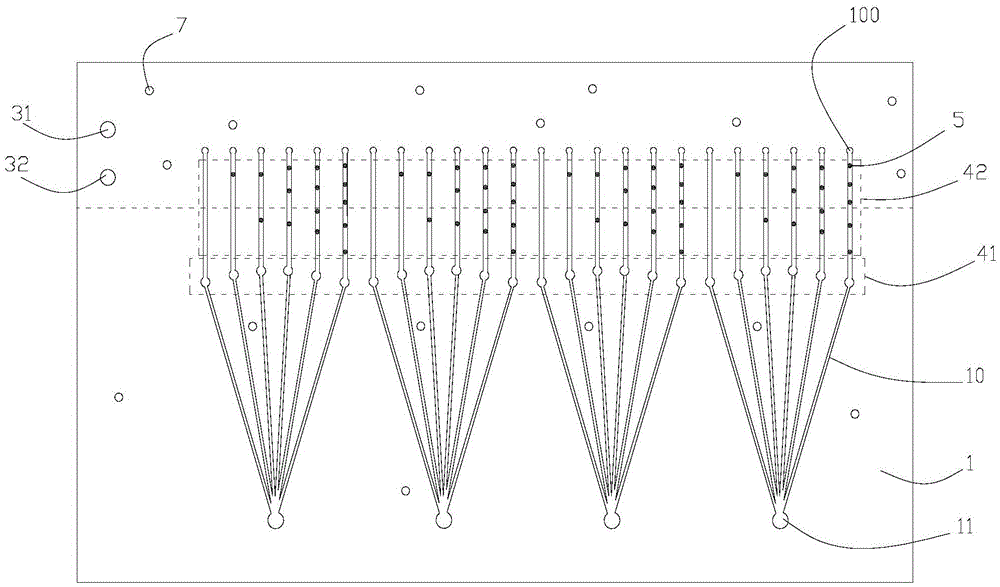

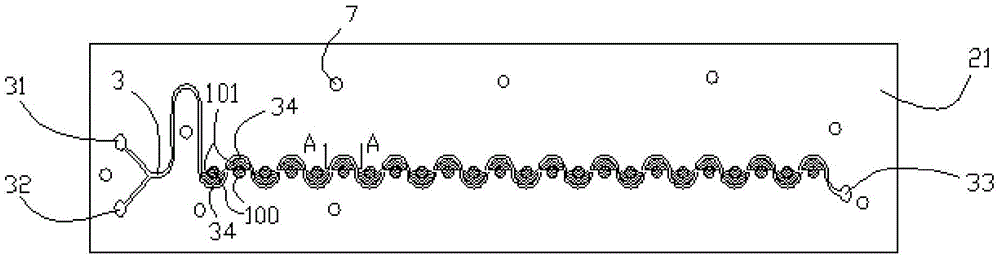

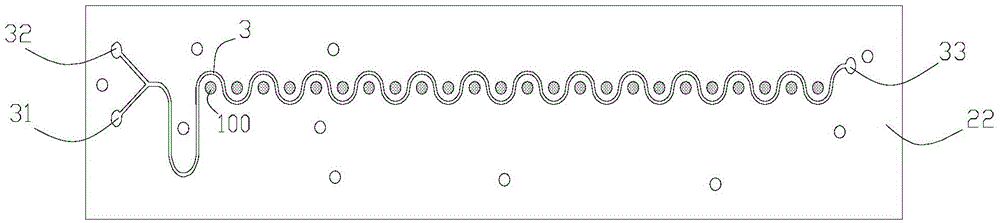

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the embodiment of the present invention includes a flow distribution control module 1 and a plurality of mass transfer modules 2 ( Figure 4 clearly shows the stacked structure), the flow distribution control module 1 is provided with a flow distribution control mechanism to deliver tributary solutions to each mass transfer module and adjust the solution flow. The mass transfer module 2 implements liquid-liquid rapid rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com