Electric heating cigarette essence capable of increasing own aroma of tobacco and preparation method and application thereof

A technology for electrically heating cigarettes and tobacco, which is applied in the fields of tobacco, application and preparation of tobacco, can solve problems such as disease hazards, and achieve the effect of improving quality and overall sensory characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, a kind of electric heating cigarette essence that increases tobacco original flavor, its specific preparation method is:

[0021] Weigh the following raw materials in parts by weight: 50 parts of Virginia tobacco reactant, 50 parts of Brazilian tobacco extract, 8 parts of benzyl alcohol, 8 parts of ethyl acetate, 4 parts of Burley tobacco extract, 3 parts of coffee extract, chocolate extract 6 parts, 841 parts of propylene glycol, 30 parts of oriental tobacco light components; the above raw materials are mixed and stirred evenly, and the essence A is prepared.

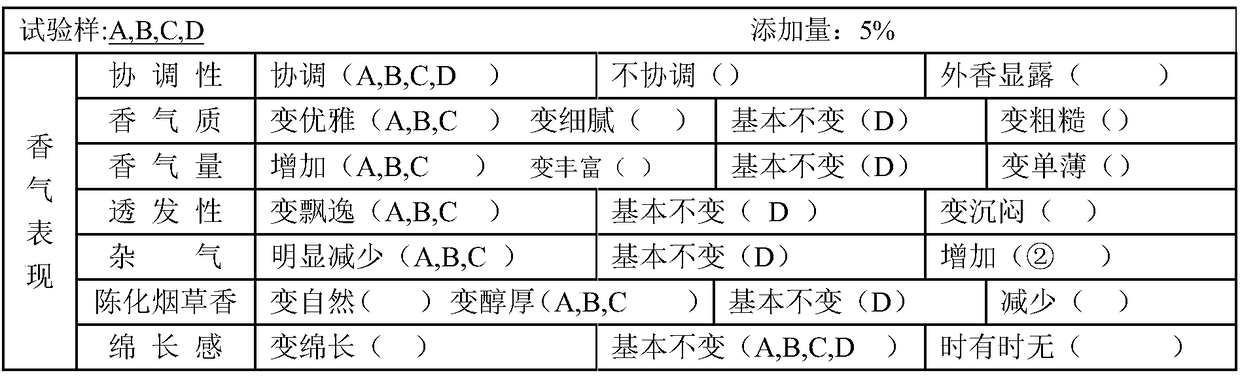

[0022] The essence A prepared in Example 1 was added to the electric heating cigarette leaf group, and its addition amount was 5% of the total weight of the leaf group;

Embodiment 2

[0023] Embodiment 2, a kind of electric heating cigarette flavor that increases the original fragrance of tobacco, its specific preparation method is:

[0024] Weigh the following raw materials in parts by weight: 50 parts of Virginia tobacco reactant, 30 parts of Brazilian tobacco extract, 10 parts of benzyl alcohol, 10 parts of ethyl acetate, 3 parts of Burley tobacco extract, 2 parts of coffee extract, 5 parts of chocolate extract, 870 parts of propylene glycol, and 20 parts of light components of oriental tobacco; mix and stir the above-mentioned raw materials to prepare flavor B.

[0025] The essence B prepared in Example 2 was added to the electric heating cigarette leaf group, and its addition amount was 5% of the total weight of the leaf group;

Embodiment 3

[0026] Embodiment 3, a kind of electric heating cigarette flavor that increases the original fragrance of tobacco, its specific preparation method is:

[0027] Weigh the following raw materials in parts by weight: 40 parts of Virginia tobacco reactant, 40 parts of Brazilian tobacco extract, 9 parts of benzyl alcohol, 9 parts of ethyl acetate, 2 parts of Burley tobacco extract, 3 parts of coffee extract, 4 parts of chocolate extract, 868 parts of propylene glycol, and 25 parts of oriental tobacco light components; mix and stir the above-mentioned raw materials evenly, and prepare essence C.

[0028] The essence C prepared in Example 3 was added to the electric heating cigarette leaf group, and the added amount was 5% of the total weight of the leaf group;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com