Package film for quick-frozen foods

A technology for quick-frozen food and packaging film, which is applied in applications, household components, household appliances, etc., to achieve the effects of not easy to break, good flexibility, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

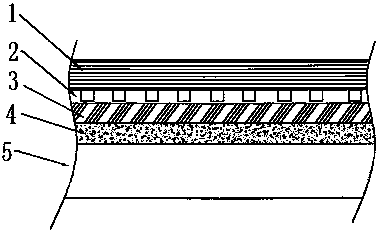

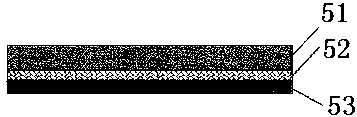

[0016] like Figure 1-2 As shown, a packaging film for quick-frozen food includes an antifreeze film layer 2, a multi-layer co-extruded antibacterial film base layer 3, a flexible film layer 4, a mechanical strength carrier layer 1 and a cleaning function layer 5. The multi-layer co-extrusion layer The bottom of the antibacterial film base layer 3 is provided with a flexible film layer 4, the bottom of the flexible layer 4 is provided with a cleaning function layer 5, the upper part of the multi-layer co-extruded antibacterial film base layer 3 is provided with an antifreeze film layer 2, and above the antifreeze film layer 2 A mechanical strength carrier layer 1 is provided; the thickness of the antifreeze film layer 2 is between 0.1-0.4mm, the thickness of the multi-layer co-extruded antibacterial film base layer 3 is between 0.3-0.8m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com