Thin-film material with high electrocaloric effect and preparation method of thin-film material

A technology of thin film material and electric card effect, which is applied in the field of high electric card effect thin film material and its preparation, 0.5BCT-0.5BZT-Fe thin film material and its preparation field, can solve the problems of poor repeatability and high cost, and achieve The effect of simplifying the preparation process, easy control and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

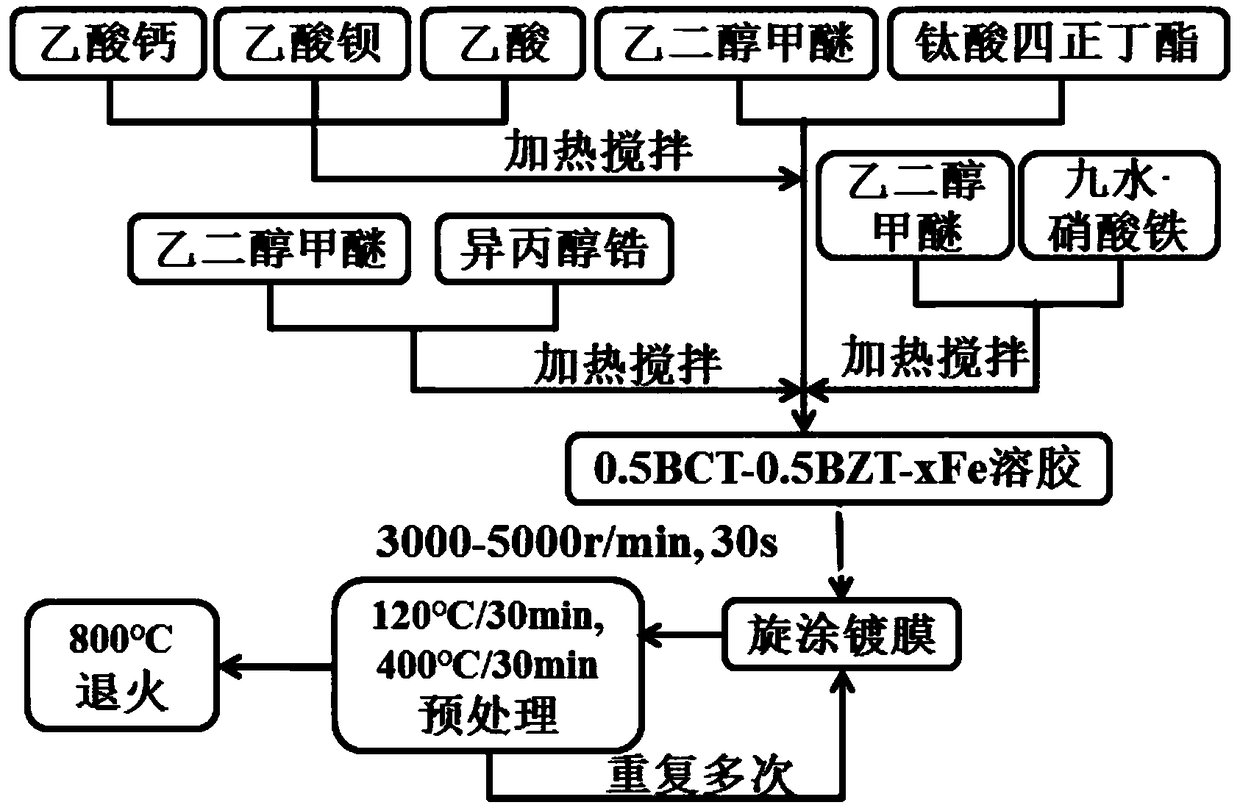

[0041] The present embodiment provides a kind of sol-gel method to prepare the method for high electrical card effect 0.5BCT-0.5BZT-Fe film material, comprises the following steps:

[0042] (1) Pt / Ti / SiO 2 Immerse the / Si substrate in acetone, absolute ethanol, and deionized water respectively, then use an ultrasonic cleaner for 15-35 minutes and dry it with an infrared lamp;

[0043] (2) According to the molar ratio of metal ions Ba:Ca:Zr:Ti:Fe is 0.85:0.15:0.1-x:0.9:x, wherein the value range of x is 0.0~0.03, weigh barium acetate and calcium acetate dissolved in Add a certain amount of acetic acid, and stir at 40-70°C until all are dissolved to obtain solution A; weigh tetra-n-butyl titanate, zirconium isopropoxide and iron nitrate nonahydrate, dissolve them in ethylene glycol methyl ether, and Stir at 40-70°C until they are all dissolved, then mix the three solutions to obtain solution B, mix solution A and solution B, use ethylene glycol methyl ether as a diluent to adju...

Embodiment 2

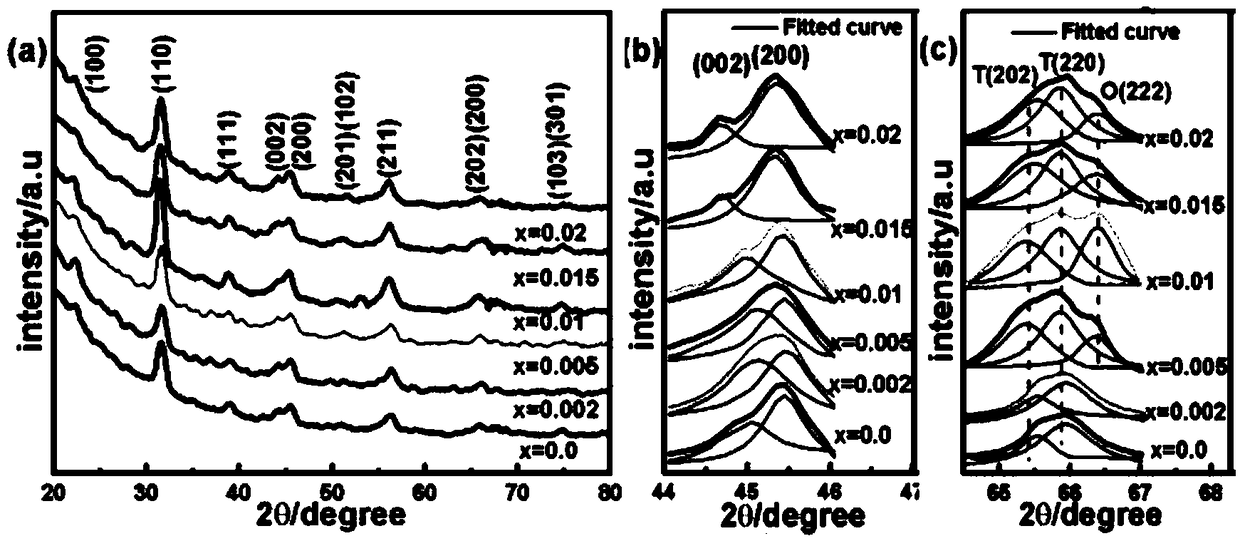

[0050] Utilize the same preparation method of embodiment 1, prepare the 0.5BCT-0.5BZT-xFe of different Fe dosages, as Figure 4 As shown, it shows that the introduction of Fe makes the 0.5BZT-0.5BCT-xFe thin film (0.005≤x≤0.02) coexist at room temperature with three ordered structures of tetragonal phase-trigonal phase-orthorhombic phase, and makes the phase transition temperature of the system drop Near room temperature and broadened the dielectric peak, showing the characteristics of a diffuse phase transition. In a wide temperature range, polar and nonpolar regions coexist, and at a lower electric field, a field-induced phase transition can occur, thereby enhancing the electrocardiographic effect. For electric card materials, the improvement of the electric card effect and the reduction of the phase transition temperature to about room temperature are the needs of practical applications.

Embodiment 3

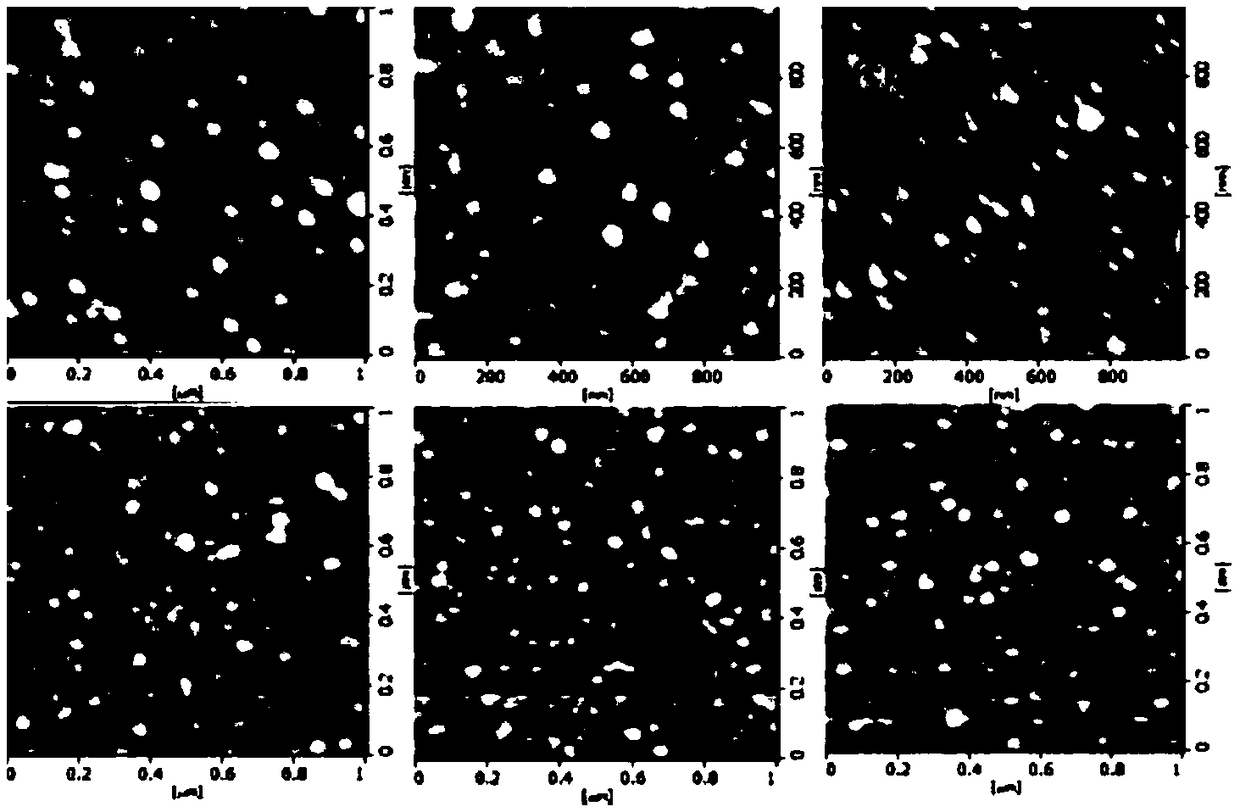

[0052] This example demonstrates the ferroelectric properties of the 0.5BCT-0.5BZT-xFe thin film material. Such as Figure 5 As shown, the 0.5BZT-0.5BCT-xFe films all exhibit good hysteresis loops. The film has the best ferroelectric properties when x=0.01, P max =25μC / cm 2 , P r =14μC / cm 2 ,E c =170kV / cm, it has a large polarization value at a lower electric field, and a large polarization value is a prerequisite for an improved electric card effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com