Test device and determining method for stability of liquid accelerating agent

A technology for testing devices and accelerators, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve the problems of lack of clear requirements for the stability of liquid accelerator products, destruction of complexation balance or hydrolysis balance, and repeatability of measurement results To achieve the effect of shortening the test cycle, accelerating the crystallization rate, and shortening the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

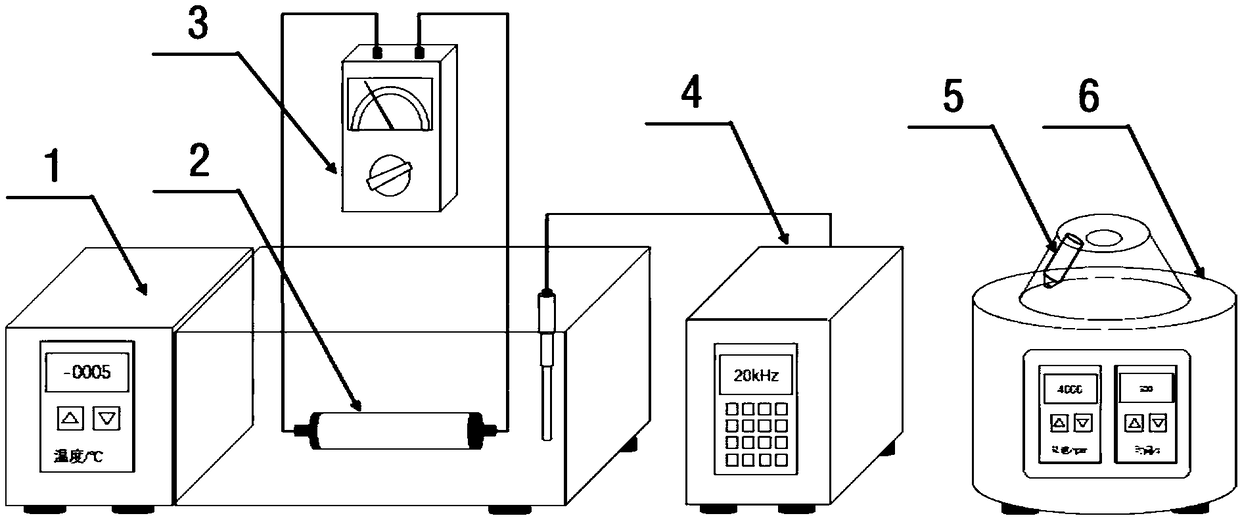

[0033] The present embodiment provides a kind of assay method of liquid quick-setting agent stability, and assay step is as follows:

[0034] (1) Select a certain quality of a light yellow, clear and transparent liquid quick-setting agent A, and pack it into the electrophoresis glass column 2;

[0035] (2) Place the electrophoretic glass column 2 with the sample A in the oil bath of the low-temperature oil bath 1 whose temperature is set to -10°C, and apply a DC voltage of 20V with the DC power supply 3 through the conductive joint at both ends, Place the oscillating end of the ultrasonic disperser 4 in the oil bath of the low-temperature oil bath box 1, set the oscillating frequency of the ultrasonic disperser 4 to 20 kHz, and keep it for 8 hours;

[0036] (3) The step of extracting a certain mass (2) The mass of the sample after processing m 1 , put into centrifuge rotor 5 and put into centrifuge 6 and centrifuge at 3000r / min speed for 10min, weigh the supernatant liquid ma...

Embodiment 2

[0040] This embodiment provides a method for measuring the stability of a liquid quick-setting agent. Compared with Example 1, the difference is that the temperature of the oil bath in the low-temperature oil bath box 1 in step (2) is set to 0°C, and the two ends are connected by conductive The connector is loaded with a DC power supply 3 and a DC voltage of 60V is applied, the oscillating end of the ultrasonic disperser 4 is placed in the oil bath of the low-temperature oil bath box 1, the oscillation frequency of the ultrasonic disperser 4 is set to 19.5kHz, and kept for 12h.

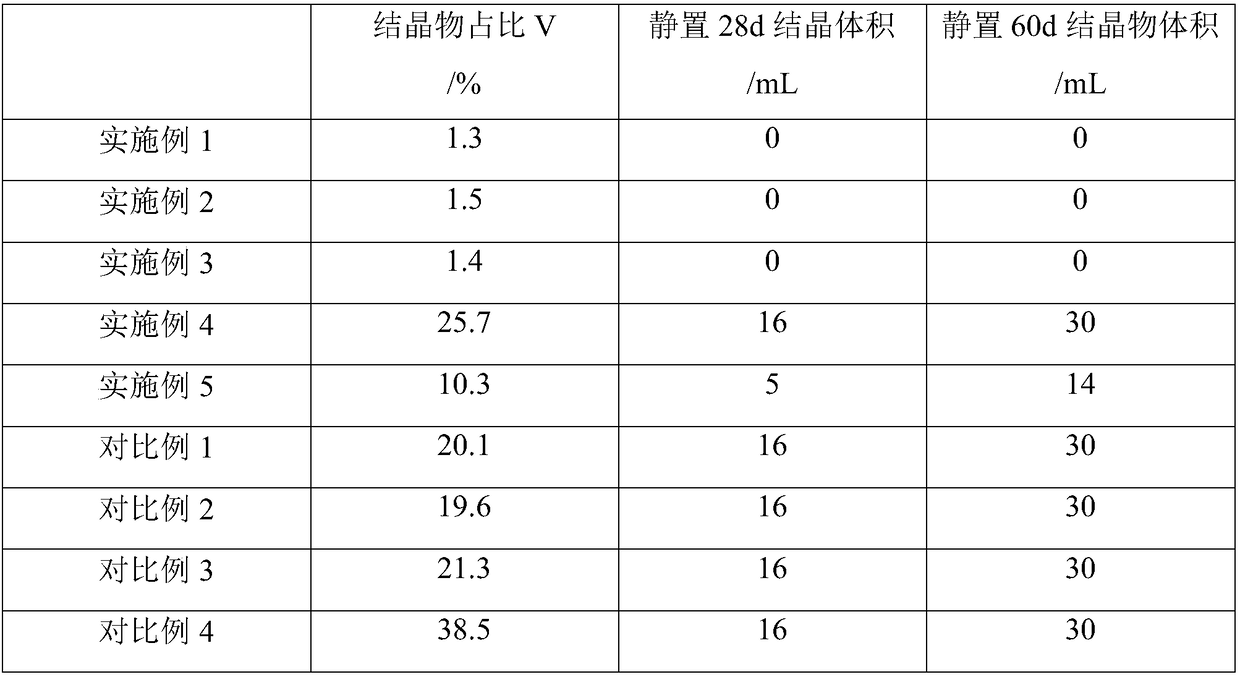

[0041] The test results are shown in Table 1, and Table 1 also shows the volume data of the crystals at the bottom of the sample at 28d and 60d measured by the static method (at 5°C).

Embodiment 3

[0043] This embodiment provides a method for measuring the stability of the liquid quick-setting agent. Compared with Example 1, the difference is that in step (3), the centrifuge 6 is centrifuged at a speed of 2000r / min for 5min.

[0044] The test results are shown in Table 1, and Table 1 also shows the volume data of the crystals at the bottom of the sample at 28d and 60d measured by the static method (at 5°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com