A Method for Suppressing Odd Harmonic Vibration of Magnetic Suspension Rotor Based on Hybrid Odd Repeat Controller

A magnetic levitation rotor and repetitive controller technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of attenuation of harmonic current suppression effect of repetitive controllers, sensitivity to unconsidered changes, and dynamic performance of the control system Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

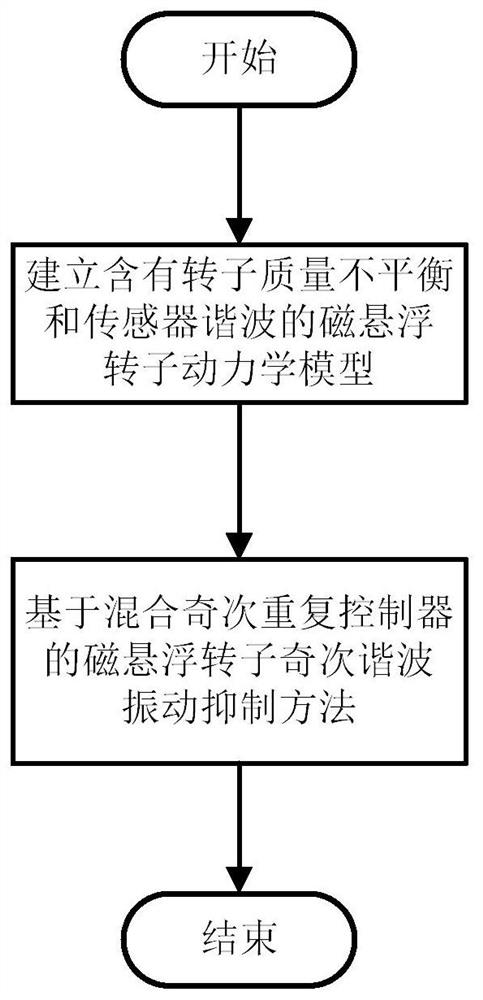

[0070] Such as figure 1 As shown, the implementation process of an odd-order harmonic vibration suppression method for a maglev rotor system based on a hybrid odd-order repetitive controller is: firstly, a maglev rotor dynamics model containing rotor mass imbalance and sensor harmonics is established; then a Odd-order harmonic vibration suppression method for maglev rotor system based on hybrid odd-order repetitive controller;

[0071] Step (1) Build a maglev rotordynamics model with mass imbalance and sensor harmonics

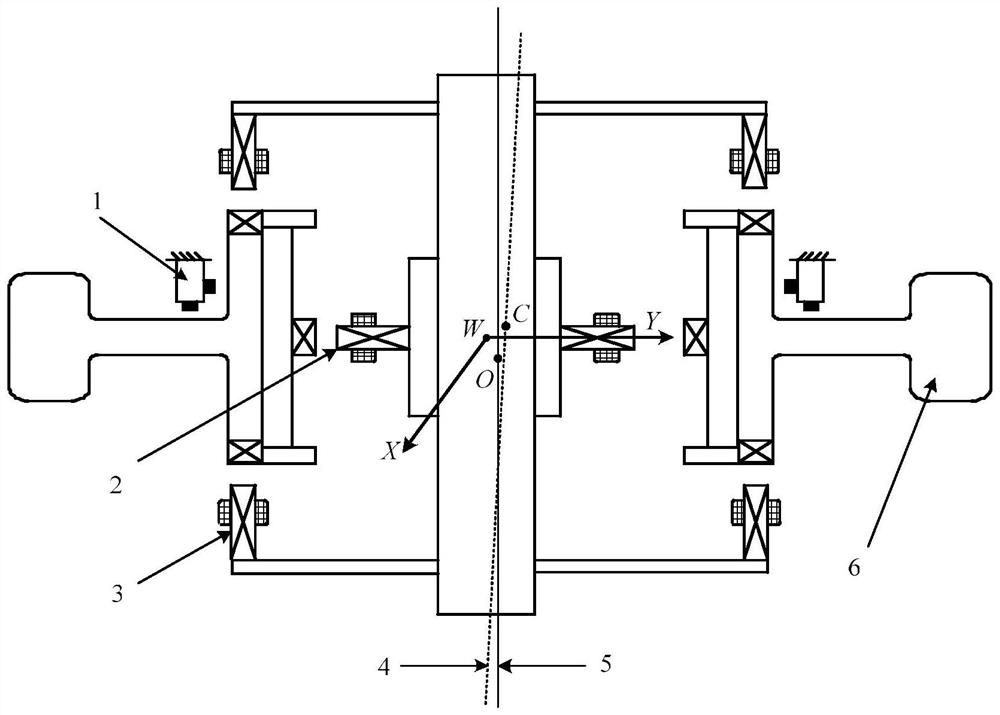

[0072] The schematic diagram of the magnetic levitation rotor system is as follows: figure 2 As shown, it includes a displacement sensor 1, a radial magnetic bearing coil 2, an axial magnetic bearing coil 3, a magnetic levitation rotor inertial axis 4, a magnetic levitation rotor geometric axis 5, and a magnetic levitation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com